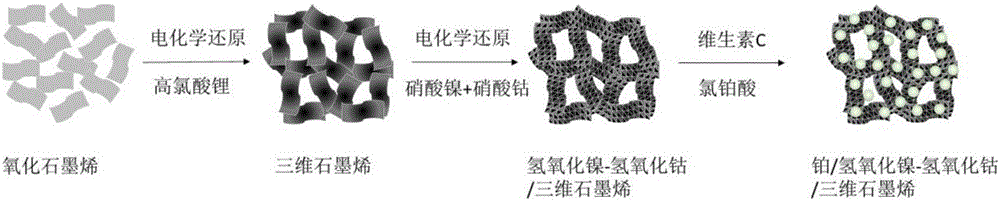

Preparation and application of platinum/nickel hydroxide-cobalt hydroxide/graphene three-dimensional composite catalyst

A technology of nickel hydroxide and cobalt hydroxide, applied in the field of nanomaterials, achieves the effects of low cost, avoiding the use of toxic reducing agents or dispersants, and low experimental operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Preparation of Composite Catalyst

[0052] According to the Hummers method, 325-mesh graphite was oxidized to graphite oxide, and a certain amount of graphite oxide was added to deionized water, and ultrasonically treated in an ultrasonic cleaning machine until the graphite oxide was uniformly dispersed, and the obtained concentration was 2 mg·mL. -1 ~4.5mg·mL -1 graphene oxide solution, and then add a certain amount of lithium perchlorate to obtain different concentrations of graphene oxide and a concentration of 0.1mol L -1 mixed solution of lithium perchlorate.

[0053] Connect the three-electrode system of reference electrode (calomel electrode), counter electrode (platinum wire electrode) and working electrode (conductive glass) on the electrochemical workstation, immerse in the mixed solution of graphene oxide and lithium perchlorate, in- Cyclic voltammetry scan in the range of 1.5V ~ 0.6V (sweep speed is 25mV s -1 ), scan 3 to 10 circles to prepare three-di...

Embodiment 2

[0065] 1. Preparation of Composite Catalyst

[0066] According to the Hummers method, 325-mesh graphite was oxidized to graphite oxide, and a certain amount of graphite oxide was added to deionized water, and ultrasonically treated in an ultrasonic cleaning machine until the graphite oxide was uniformly dispersed, and the obtained concentration was 2 mg·mL. -1 ~4.5mg·mL -1 graphene oxide solution, and then add a certain amount of lithium perchlorate to obtain different concentrations of graphene oxide and a concentration of 0.1mol L -1 mixed solution of lithium perchlorate.

[0067] Connect the three-electrode system of reference electrode (calomel electrode), counter electrode (platinum wire electrode) and working electrode (conductive glass) on the electrochemical workstation, immerse in the mixed solution of graphene oxide and lithium perchlorate, in- Cyclic voltammetry scan in the range of 1.5V ~ 0.6V (sweep speed is 25mV s -1 ), scan 3 to 10 circles to prepare three-di...

Embodiment 3

[0071] 1. Preparation of Composite Catalyst

[0072] According to the Hummers method, 325-mesh graphite was oxidized to graphite oxide, and a certain amount of graphite oxide was added to deionized water, and ultrasonically treated in an ultrasonic cleaning machine until the graphite oxide was uniformly dispersed, and the obtained concentration was 2 mg·mL. -1 ~4.5mg·mL -1 graphene oxide solution, and then add a certain amount of lithium perchlorate to obtain different concentrations of graphene oxide and a concentration of 0.1mol L -1 mixed solution of lithium perchlorate.

[0073] Connect the three-electrode system of reference electrode (calomel electrode), counter electrode (platinum wire electrode) and working electrode (conductive glass) on the electrochemical workstation, immerse in the mixed solution of graphene oxide and lithium perchlorate, in- Cyclic voltammetry scan in the range of 1.5V ~ 0.6V (sweep speed is 25mV s -1 ), scan 3 to 10 circles to prepare three-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com