Waterproof putty for building inner wall and preparation method thereof

A water-resistant putty, a technology in buildings, used in filling slurry and other directions, can solve the problems of unstable chemical properties, low bonding strength, poor water resistance, etc., to achieve good water resistance and gloss, strong adhesion, dryness short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

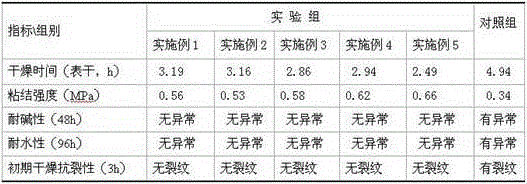

Examples

Embodiment 1

[0043] Example 1 Water-resistant putty for building interior walls is prepared from the following raw materials (23 kg for each part): 10 parts of polyvinyl alcohol, 12 parts of hydroxypropyl methylcellulose, 90 parts of heavy calcium carbonate, and 12 parts of paraffin wax , 8 parts of micropowder silica gel, 10 parts of polyvinyl chloride, 18 parts of kaolin, 11 parts of talcum powder, 1.3 parts of high-carbon alcohol fatty acid ester compound, 2.5 parts of diatomaceous earth, 1.8 parts of benzoic acid, and 1.2 parts of lignin.

[0044] The preparation steps of water-resistant putty for building interior walls are as follows:

[0045] (1) Crush the polyvinyl alcohol, put it in the reaction tank, add 3 times the mass of water, add micropowder silica gel after standing for 2 hours, heat to 56°C, keep warm for 2 hours, stir evenly, filter, cool to room temperature, and dry , ground and passed through an 80-mesh sieve;

[0046] (2) Put heavy calcium carbonate and paraffin in a ...

Embodiment 2

[0051] Example 2 The water-resistant putty for building interior walls is prepared from the following raw materials (14 kg for each part): 16 parts of polyvinyl alcohol, 20 parts of hydroxypropyl methylcellulose, 103 parts of heavy calcium carbonate, and 18 parts of paraffin , 13 parts of micropowdered silica gel, 16 parts of polyvinyl chloride, 24 parts of kaolin, 15 parts of talcum powder, 1.6 parts of higher alcohol fatty acid ester complex, 3.2 parts of diatomaceous earth, 2.2 parts of benzoic acid, and 1.6 parts of lignin.

[0052] The preparation steps of water-resistant putty for building interior walls are as follows:

[0053] (1) Crush polyvinyl alcohol, put it in a reaction tank, add 5 times the mass of water, add micropowder silica gel after standing for 3 hours, heat to 62°C, keep warm for 4 hours, stir evenly, filter, cool to room temperature, and dry , ground, passed through a 120-mesh sieve, and set aside;

[0054] (2) Put heavy calcium carbonate and paraffin i...

Embodiment 3

[0059] Example 3 Water-resistant putty for building interior walls is prepared from the following raw materials (15 kg for each part): 12 parts of polyvinyl alcohol, 15 parts of hydroxypropyl methylcellulose, 95 parts of heavy calcium carbonate, and 14 parts of paraffin , 10 parts of micronized silica gel, 12 parts of polyvinyl chloride, 20 parts of kaolin, 12 parts of talcum powder, 1.4 parts of higher alcohol fatty acid ester complex, 2.7 parts of diatomaceous earth, 1.9 parts of benzoic acid, and 1.3 parts of lignin.

[0060] The preparation steps of water-resistant putty for building interior walls are as follows:

[0061] (1) Crush the polyvinyl alcohol, put it in the reaction tank, add 3.5 times the mass of water, add micropowder silica gel after standing for 2.3 hours, heat to 58°C, keep warm for 2.5 hours, stir evenly, filter, cool to room temperature, and dry , ground, passed through a 90-mesh sieve, and set aside;

[0062] (2) Put heavy calcium carbonate and paraffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com