Vinylene carbonate-based lithium ion battery polymer electrolyte and preparation method as well as application thereof

A polyvinylene carbonate-based lithium and polyvinylene carbonate-based technology is applied in the application field of room temperature all-solid-state lithium-ion batteries, and can solve the problems of low discharge specific capacity, low ionic conductivity, low mechanical strength, etc. High ionic conductivity, easy availability of materials, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

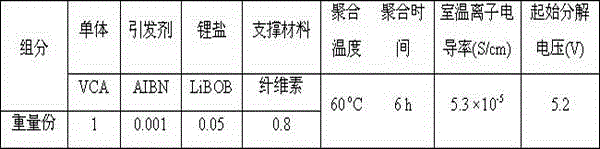

[0041] The LiBOB / VCA solution was prepared in a glove box filled with argon, and after adding AIBN to the LiBOB / VCA solution, the solution was injected into a lithium battery with cellulose as a support material. The battery is placed in 60 o After heating at C for 6 hours, VCA polymerized in situ inside the battery to obtain a polymer, and at the same time compounded with support materials and lithium salts to obtain a polymer electrolyte for lithium-ion batteries.

[0042] The mass fraction of AIBN in the LiBOB / VCA solution was 0.1%.

[0043] The ratio of raw materials used to prepare polymer electrolytes for lithium-ion batteries is shown in Table 1. The ion conductivity of polymer electrolytes for lithium-ion batteries prepared at room temperature is 5.3×10 -5 S / cm, the initial decomposition voltage is 5.2V.

[0044] Table 1:

[0045]

Embodiment 2

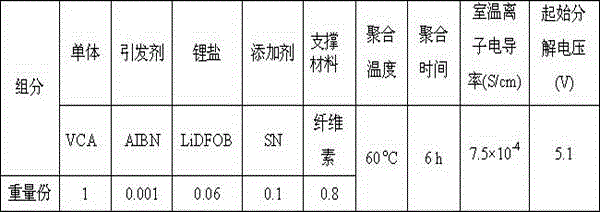

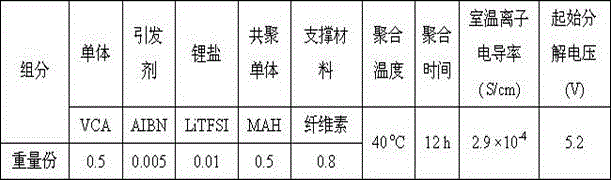

[0047] MAH was added to VCA in an argon-filled glove box to prepare a LiTFSI / VCA-MAH solution. After adding AIBN to the LiTFSI / VCA-MAH solution, the solution was injected into a lithium battery with cellulose as a support material. The battery is placed in 40 o After heating at C for 12 hours, VCA-MAH polymerized in situ inside the battery to obtain a copolymer, and at the same time compounded with support materials and lithium salts to obtain a lithium-ion battery polymer electrolyte.

[0048] The mass ratio of VCA and MAH was 5:5, and the mass fraction of AIBN in LiTFSI / VCA-MAH solution was 0.5%.

[0049] The ratio of raw materials used to prepare polymer electrolytes for lithium-ion batteries is shown in Table 2. The ion conductivity of polymer electrolytes for lithium-ion batteries prepared at room temperature is 2.9 × 10 -4 S / cm, the initial decomposition voltage is 5.2V.

[0050] Table 2:

[0051]

Embodiment 3

[0053] Preparation of LiClO by adding VAc to VCA in an argon-filled glove box 4 / VCA-VAc solution, to LiClO 4 After adding AIBN to the VCA-VAc solution, the solution was injected into a lithium battery supported by glass fiber. The battery is placed in 60 o After heating at C for 8 hours, VCA-VAc polymerized in situ inside the battery to obtain a copolymer, and at the same time compounded with support materials and lithium salts to obtain a lithium-ion battery polymer electrolyte.

[0054] Wherein the mass ratio of VCA and MAH is 8:2, AIBN is in LiClO 4 The mass fraction in VCA-VAc solution is 0.8%.

[0055] The ratio of raw materials used to prepare polymer electrolytes for lithium-ion batteries is shown in Table 3. The ion conductivity of polymer electrolytes for lithium-ion batteries prepared at room temperature is 1.7×10 -4 S / cm, the initial decomposition voltage is 4.6V.

[0056] table 3:

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com