Preparation method for polyvinylidene fluoride (PVDF) porous film

A technology of polyvinylidene fluoride and porous film, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of separation and treatment of oil/water mixture limited by the preparation of polymer separation membranes, and achieve low cost and high raw material Ease of availability, good mechanical strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

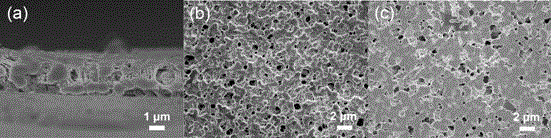

[0029] (1) Preparation of polymer precursor solution: 0.6 g of polyvinylidene fluoride (PVDF) powder was added to 10 mL of dimethylformamide (DMF) solvent, and stirred for 30 min to form a concentration of 6% PVDF / DMF translucent solution. Add 0.168 g (8 mmol) citric acid monohydrate (CAM) particles to 10 mL of the above solution, and stir for another 30 min to form a transparent mixed solution before use.

[0030] (2) Forming of the film: prepare a glass plate of fixed size (8×8×8 cm) in advance, first clean it ultrasonically with acetone for 20 min, then rinse it with deionized water and ethanol in turn, and finally dry it before use. Take 2 mL of the above-prepared CAM / PVDF / DMF precursor solution with a plastic straw, drop it on the cleaned glass substrate, spread the solution completely by casting method, and place it in an oven at 60 °C obliquely. After 30 min, the PVDF film containing CAM grains was solidified and formed on the glass substrate.

[0031] (3) The detach...

Embodiment 2

[0035] (1) Preparation of polymer precursor solution: 0.6 g of polyvinylidene fluoride (PVDF) powder was added to 10 mL of dimethylformamide (DMF) solvent, and stirred for 30 min to form a concentration of 6% PVDF / DMF translucent solution. Add 0.126g (6mmol) citric acid monohydrate (CAM) particles to 10 mL of the above solution, and stir for another 30 min to form a transparent mixed solution before use.

[0036] (2) Forming of the film: prepare a glass plate of fixed size (8×8×8 cm) in advance, first clean it ultrasonically with acetone for 20 min, then rinse it with deionized water and ethanol in turn, and finally dry it before use. Take 2 mL of the above-prepared CAM / PVDF / DMF precursor solution with a plastic straw, drop it on the cleaned glass substrate, spread the solution completely by casting method, and place it in an oven at 60 °C obliquely. After 30 min, the PVDF film containing CAM grains was solidified and formed on the glass substrate.

[0037] (3) The detachme...

Embodiment 3

[0040] (1) Preparation of polymer precursor solution: 0.4 g of polyvinylidene fluoride (PVDF) powder was added to 10 mL of dimethylformamide (DMF) solvent, and stirred for 30 min to form a concentration of 4% PVDF / DMF translucent solution. Add 0.126 g (6 mmol) of citric acid monohydrate (CAM) particles to 10 mL of the above solution, and stir for another 30 min to form a transparent mixed solution before use.

[0041] (2) Forming of the film: Prepare a glass plate of fixed size (8×8×8 cm) in advance, first clean it ultrasonically with acetone for 20 min, then rinse it with deionized water and ethanol in turn, and finally dry it before use. Take 2 mL of the above-prepared CAM / PVDF / DMF precursor solution with a plastic straw, drop it on the cleaned glass substrate, spread the solution completely by casting method, and place it in an oven at 60 °C obliquely. After 30 min, the PVDF film containing CAM grains was solidified and formed on the glass substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com