Catalyst for preparing succinic anhydride from maleic anhydride through low-temperature hydrogenation and preparation method and application of catalyst

A technology for producing succinic anhydride and catalysts, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large amount of precious metal usage, high reaction pressure, and increased cost, and achieve a wide range of solvent choices , mild reaction conditions, high hydrogenation activity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

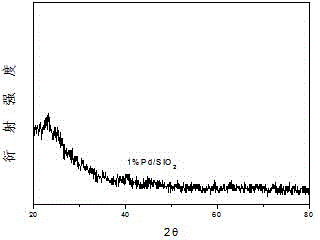

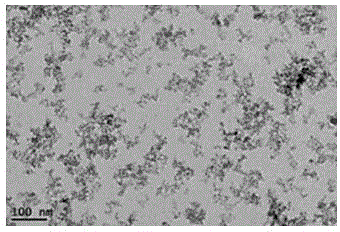

[0021] Take a certain amount of SiO 2 In the muffle furnace air atmosphere, the temperature was raised to 500 °C for 2 h at 20 °C / min, and then cooled to room temperature; 50 mmol / L chloropalladium acid aqueous solution and a certain amount of distilled water were weighed and impregnated on the above-mentioned roasted carrier, and the palladium loading was controlled as 1 wt%, the volume ratio of the carrier to the palladium solution was 1:4, ultrasonically dispersed for 2 h, and then dried in an oven at 80°C for 10 h; the hydrogen space velocity was 6000 ml / g / h under normal pressure for reduction treatment, the reduction process first The temperature was raised from room temperature to 120 °C at 5 °C / min and kept for 1 h, and then raised to 250 °C at 20 °C / min, then rapidly cooled to 200 °C and kept for 1 h, and then lowered to room temperature to obtain catalyst A. The ICP-AES test shows that the actual palladium loading is 0.97%, and the XRD and TEM characterization results...

Embodiment 2

[0023] Take a certain amount of Al 2 o 3 The preparation process of the carrier is roughly the same as that of Example 1, but during the reduction process, the temperature is raised to 250 °C at 20 °C / min and then kept for 0.5 h, and then rapidly lowered to 200 °C and kept for 1 h to obtain catalyst B.

Embodiment 3

[0025] Take a certain amount of activated carbon carrier and heat it up to 300°C for 2 h in a tube furnace nitrogen atmosphere at 5°C / min. The rest is the same as in Example 1 to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com