Functionalized ionic liquid-modified carbon nanotube and method for immobilizing lipase through carbon nanotube

A technology of ionic liquids and carbon nanotubes, applied in the direction of fixing on or in inorganic carriers, fixing on/in organic carriers, nanotechnology, etc., can solve the problem of weak binding force between enzyme molecules and carriers, immobilization Reduce efficiency and stability, pollute catalytic reaction products and other problems, achieve simple apparent activity and repeated use effect, improve enzymatic properties, and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Purification and oxidation of carbon nanotubes: take 1 g of original carbon nanotubes and stir in 2.6M nitric acid solution for 24 hours under reflux. Add 10 mg of purified carbon nanotubes to 40 ml of concentrated nitric acid and concentrated sulfuric acid mixture, ultrasonicate for 3 hours, add water to dilute, filter and wash until neutral, vacuum dry overnight, grind for later use, and obtain carboxylated carbon nanotubes (MWCNTs-COOH).

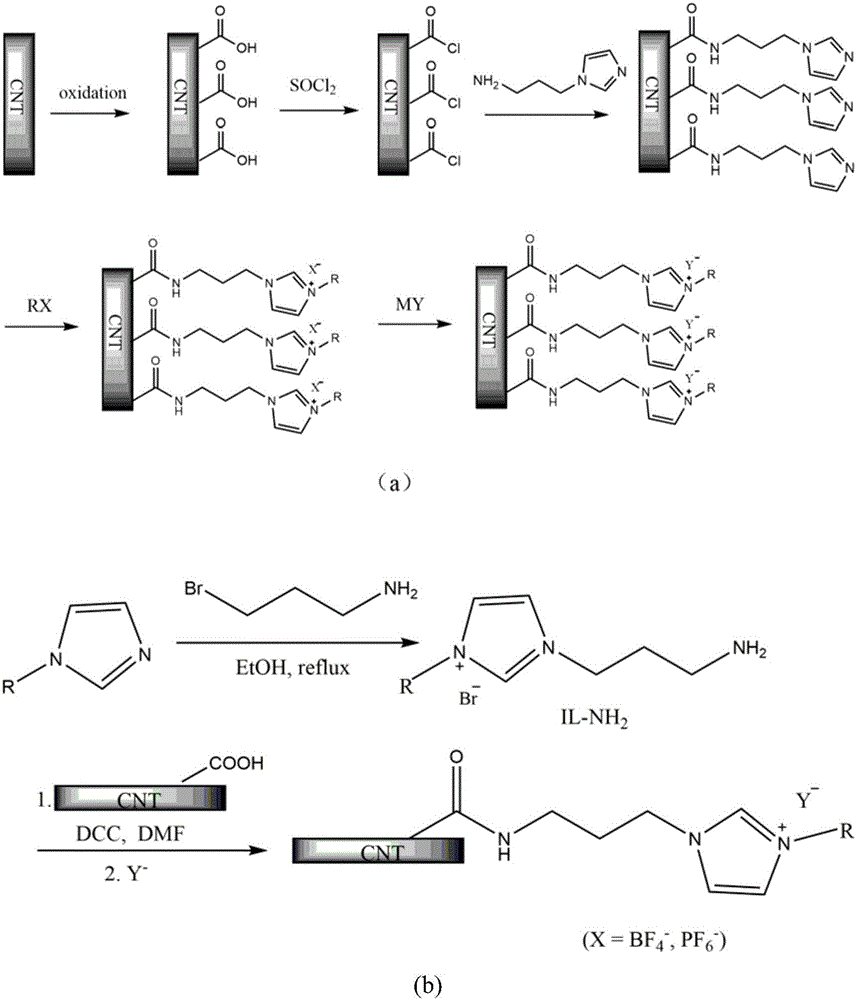

[0049](2) Preparation of functionalized ionic liquid-modified carbon nanotube immobilized enzyme carrier: a certain molar ratio of 1-methylimidazole and 3-bromopropylamine hydrobromide was mixed in absolute ethanol solvent and refluxed for 24 hours. The reaction product was dissolved with a small amount of water after removal of solvent and volatile unreacted substances, and potassium hydroxide was added to adjust the pH to 8.0. The resulting solution was distilled off under reduced pressure to remove most of the water, then dr...

Embodiment 2

[0062] 1) Purification and oxidation of carbon nanotubes: same as described in Example 1.

[0063] 2) Preparation of functionalized ionic liquid-modified carbon nanotube-immobilized enzyme carrier: a certain molar ratio of 1-ethylimidazole and 3-bromopropylamine hydrobromide was mixed in absolute ethanol solvent, and refluxed for 24 hours. The reaction product was dissolved with a small amount of water after removal of solvent and volatile unreacted substances, and potassium hydroxide was added to adjust the pH to 8.0. The resulting solution was distilled off under reduced pressure to remove most of the water, then dried in vacuo to constant weight, and the product was extracted with a mixed solvent of ethanol-tetrahydrofuran, the filtrate was collected and distilled under reduced pressure to recover the solvent, and then dried in vacuo to constant weight to obtain a yellow viscous liquid 1-(1 -aminopropyl)-3-ethylimidazolium bromide (IL-NH 2 ). MWCNTs-COOH, IL-NH 2 1. DCC ...

Embodiment 3

[0067] 1) Purification and oxidation of carbon nanotubes: same as described in Example 1.

[0068] 2) Preparation of functionalized ionic liquid-modified carbon nanotube-immobilized enzyme carrier: a certain molar ratio of 1-butylimidazole and 3-bromopropylamine hydrobromide was mixed in absolute ethanol solvent, and refluxed for 24 hours. The reaction product was dissolved with a small amount of water after removal of solvent and volatile unreacted substances, and potassium hydroxide was added to adjust the pH to 8.0. The resulting solution was distilled off under reduced pressure to remove most of the water, then dried in vacuo to constant weight, and the product was extracted with a mixed solvent of ethanol-tetrahydrofuran, the filtrate was collected and distilled under reduced pressure to recover the solvent, and then dried in vacuo to constant weight to obtain a yellow viscous liquid 1-(1 -aminopropyl)-3-butylimidazolium bromide (IL-NH 2 ). MWCNTs-COOH, IL-NH 2 , DCC w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com