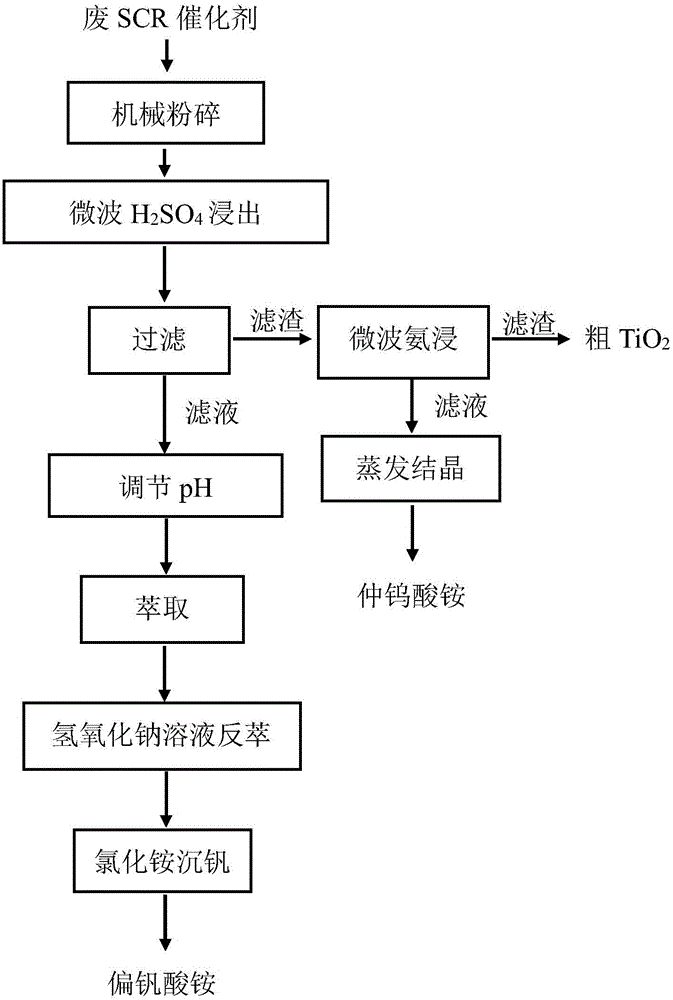

Comprehensive recycling method for waste SCR catalysts

A technology of SCR catalyst and extractant, applied in the field of comprehensive recovery and utilization of waste SCR catalyst, can solve the problems of high energy consumption and increase production cost, and achieve the effects of low energy consumption, reduced recovery cost and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

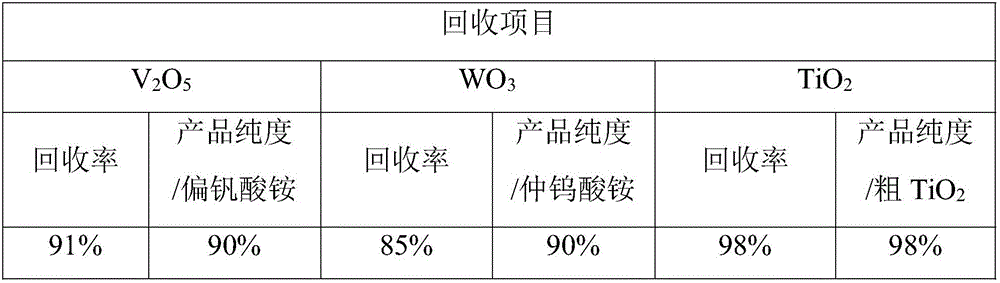

Embodiment 1

[0032] The waste SCR catalyst is mechanically crushed until it passes through a 20-mesh sieve; the crushed waste SCR catalyst is sent to a concentration of 6M H 2 SO 4 In the solution, microwave leaching is carried out at a temperature of 100°C, the microwave power is 1200W, the liquid-solid ratio is 1:1, and the leaching time is 6h; the acid leaching solution and leaching residue are obtained through solid-liquid separation, and the leaching residue is fed into ammonia with a concentration of 25%. In the aqueous solution, microwave leaching is carried out at a temperature of 100°C, the microwave power is 1200W, the liquid-solid ratio is 1:2, and the leaching time is 6h; after solid-liquid separation, the leaching solution containing ammonium paratungstate is obtained, and ammonium paratungstate can be obtained by evaporation and crystallization, and the filter residue is crude TiO 2 Adding acid to the pickling solution to adjust the pH to 10, using 5,8-diethyl-7-hydroxyl-6-do...

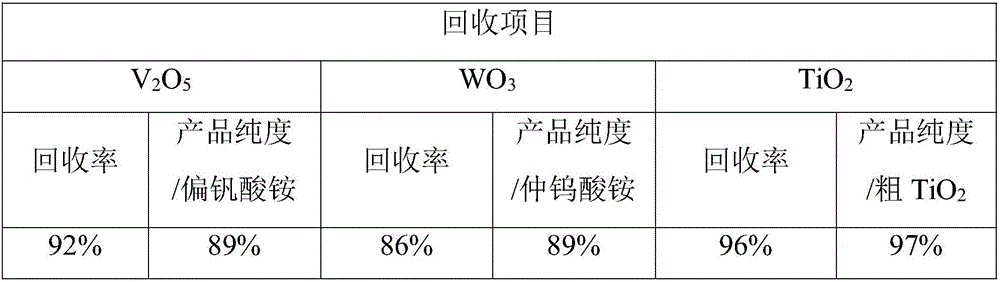

Embodiment 2

[0037] Mechanically pulverize the spent SCR catalyst until it passes through a 20-mesh sieve; send the pulverized spent SCR catalyst into H2O with a concentration of 10M 2 SO 4In the solution, microwave leaching was carried out at a temperature of 200°C, the microwave power was 600W, the liquid-solid ratio was 10:1, and the leaching time was 5h; the acid leaching solution and leaching slag were obtained through solid-liquid separation, and the leaching slag was fed into ammonia with a concentration of 10%. In the aqueous solution, microwave leaching is carried out at a temperature of 60°C, the microwave power is 600W, the liquid-solid ratio is 10:1, and the leaching time is 2 hours; after solid-liquid separation, the leaching solution containing ammonium paratungstate is obtained, and ammonium paratungstate can be obtained by evaporation and crystallization, and the filter residue is crude TiO 2 Adding acid to the pickling solution to adjust the pH to 4, using 5,8-diethyl-7-hy...

Embodiment 3

[0042] Carry out mechanical pulverization to waste SCR catalyst, to pass through 20 mesh sieves; Send the waste SCR catalyst after pulverization into the concentration of 5M H 2 SO 4 In the solution, microwave leaching was carried out at a temperature of 110°C, with a microwave power of 800W, a liquid-solid ratio of 20:1, and a leaching time of 4 hours; the acid leaching solution and leaching residue were obtained through solid-liquid separation, and the leaching residue was fed into ammonia with a concentration of 25%. In the aqueous solution, microwave leaching is carried out at a temperature of 90°C, the microwave power is 600W, the liquid-solid ratio is 5:1, and the leaching time is 2 hours; after solid-liquid separation, the leaching solution containing ammonium paratungstate is obtained, and ammonium paratungstate can be obtained by evaporation and crystallization, and the filter residue is crude TiO 2 Adding acid to the pickling solution to adjust the pH to 7, using 5,8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com