Contacting passivation crystalline silicon solar cell structure and preparation method

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of high recombination at the opening and only battery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

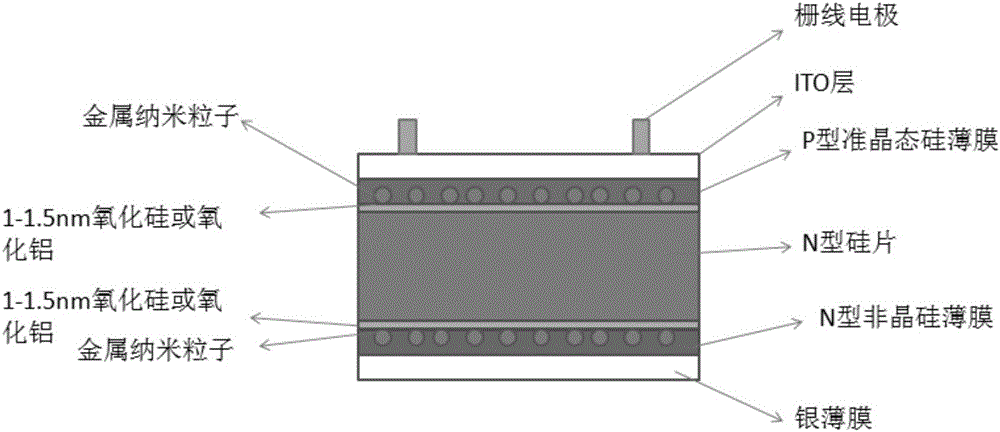

Embodiment 1

[0036] 1. Polish the 180um P-type silicon wafer on both sides, and then perform RCA cleaning

[0037] 2. Double-sided aluminum oxide film is prepared by ALD with a thickness of 1-1.5nm; hot nitric acid oxidation or ultraviolet ozone treatment can also be used to form a silicon oxide film of 1-1.5nm.

[0038] 3. A 50nm gold thin film is prepared by thermal evaporation on both sides of the silicon wafer, and then annealed at 400 degrees to form metal nanoparticles. The annealing process can also enhance the passivation effect of the passivation film.

[0039] 4. Prepare an N-type quasi-crystalline silicon film on the light-receiving surface with a thickness of 10nm; the method used is PECVD. The quasi-crystalline silicon film is a film between amorphous and microcrystalline close to the microcrystalline silicon phase, which can be adjusted by adjusting The preparation process is obtained, and then the 70nm ITO film is prepared by electron beam evaporation or sputtering, and fina...

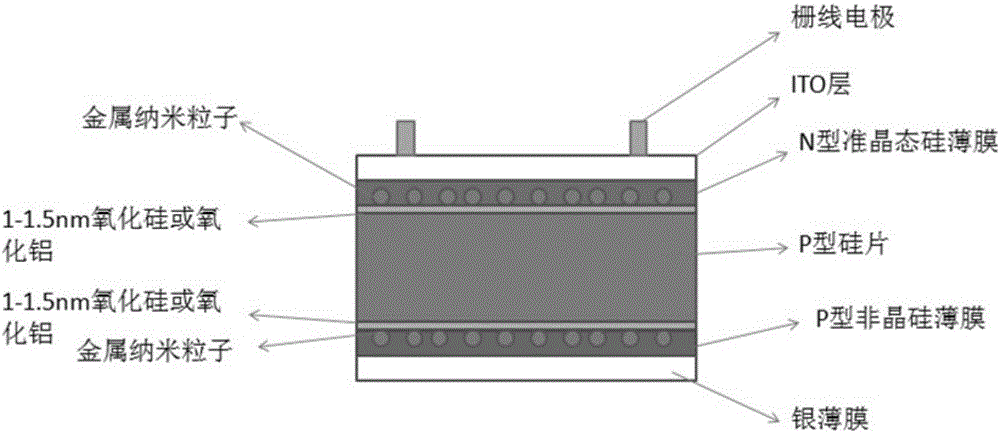

Embodiment 2

[0042] 1. Polish the 180um N-type silicon wafer on both sides, and then perform RCA cleaning.

[0043] 2. Double-sided aluminum oxide film is prepared by ALD, with a thickness of 1-1.5nm. It can also be oxidized with hot nitric acid, or treated with ultraviolet and ozone to form a silicon oxide film of 1-1.5nm.

[0044] 3. A 100nm gold film is prepared by thermal evaporation on both sides of the silicon wafer, and then annealed at 400 degrees to form metal nanoparticles. The annealing process can also enhance the passivation effect of the passivation film.

[0045] 4. Prepare a P-type quasi-crystalline silicon film on the light-receiving surface with a thickness of 15nm. The method used is PECVD. The quasi-crystalline silicon film is a film between amorphous and microcrystalline close to the microcrystalline silicon phase. It can be obtained by adjusting the preparation process, and then the 80nm ITO film is prepared. The method used is electron beam evaporation. Or sputterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com