A kind of preparation method of lead oxide-carbon composite material

A technology of carbon composite materials and lead oxide, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of unsatisfactory hydrogen evolution suppression effect, achieve the effects of overcoming inconsistency, improving cycle life, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of lead oxide-carbon composite material provided by the invention comprises the following steps:

[0030] (1) For each gram of carbon material, add 300 ml of 0.05M to 0.5M lead oxide precursor solution, mix evenly and adjust the pH value between 8.5-9.0, and dry the solid phase after solid-liquid separation to obtain a raw material mixture;

[0031] The carbon material is one or more of activated carbon, carbon black, carbon nanotubes, and graphene oxide; the lead oxide precursor is a divalent lead ion solution, such as lead nitrate solution, lead acetate solution; the pH value can be adjusted Use ammonia water or strong alkali solution, such as potassium hydroxide solution, sodium hydroxide solution.

[0032] (2) calcining the raw material mixture obtained in step (1) at 500° C. to 800° C. for 2 hours under a protective gas atmosphere to obtain a lead oxide-carbon composite;

[0033] (3) The lead oxide-carbon composite obtained in the step (2), ...

Embodiment 1

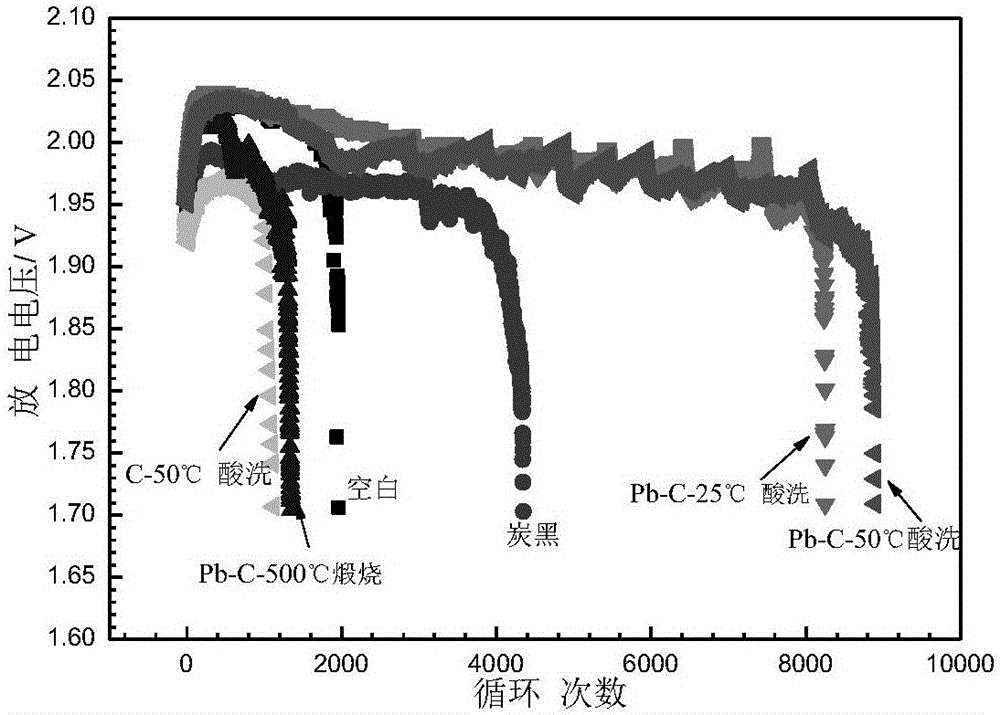

[0038] A preparation method of lead oxide-carbon composite material, comprising the following steps:

[0039] (1) For each gram of carbon material, add 300ml of 0.05M lead nitrate solution to mix evenly and adjust the pH value between 8.5-9.0, and dry the solid phase after solid-liquid separation to obtain the raw material mixture;

[0040] The carbon material is carbon black; the lead oxide precursor is lead nitrate solution; and ammonia water is used to adjust the pH value.

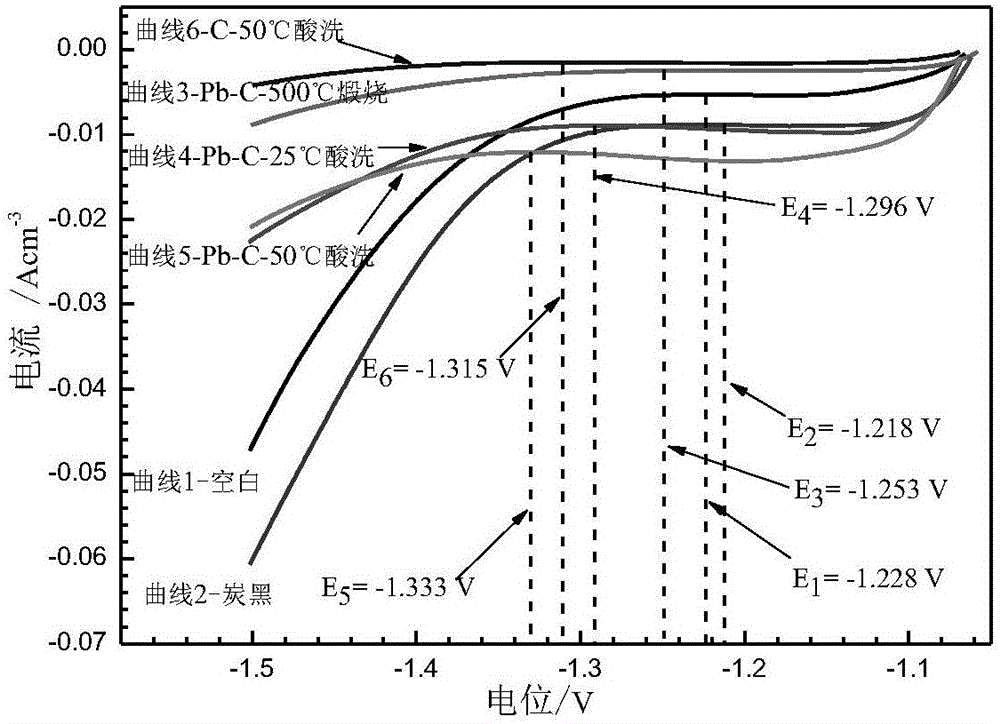

[0041] (2) calcining the raw material mixture obtained in step (1) at 500° C. for 2 hours under nitrogen to obtain a lead oxide-carbon composite;

[0042] (3) The lead oxide-carbon composite obtained in step (2) is fully washed by adding 100ml of hydrochloric acid solution with a hydrogen ion content of 5M at 25°C, rinsed until the pH value is neutral, and dried to obtain the obtained lead oxide-carbon composites.

[0043] The specific steps of full washing are as follows: use magnetic stirring for 30...

Embodiment 2

[0048] A preparation method of lead oxide-carbon composite material, comprising the following steps:

[0049] (1) For each gram of carbon material, add 300ml of 0.05M lead nitrate solution to mix evenly and adjust the pH value between 8.5-9.0, and dry the solid phase after solid-liquid separation to obtain the raw material mixture;

[0050] The carbon material is carbon black; the lead oxide precursor is lead nitrate solution; and ammonia solution is used to adjust the pH value.

[0051] (2) calcining the raw material mixture obtained in step (1) at 500° C. for 2 hours under nitrogen to obtain a lead oxide-carbon composite;

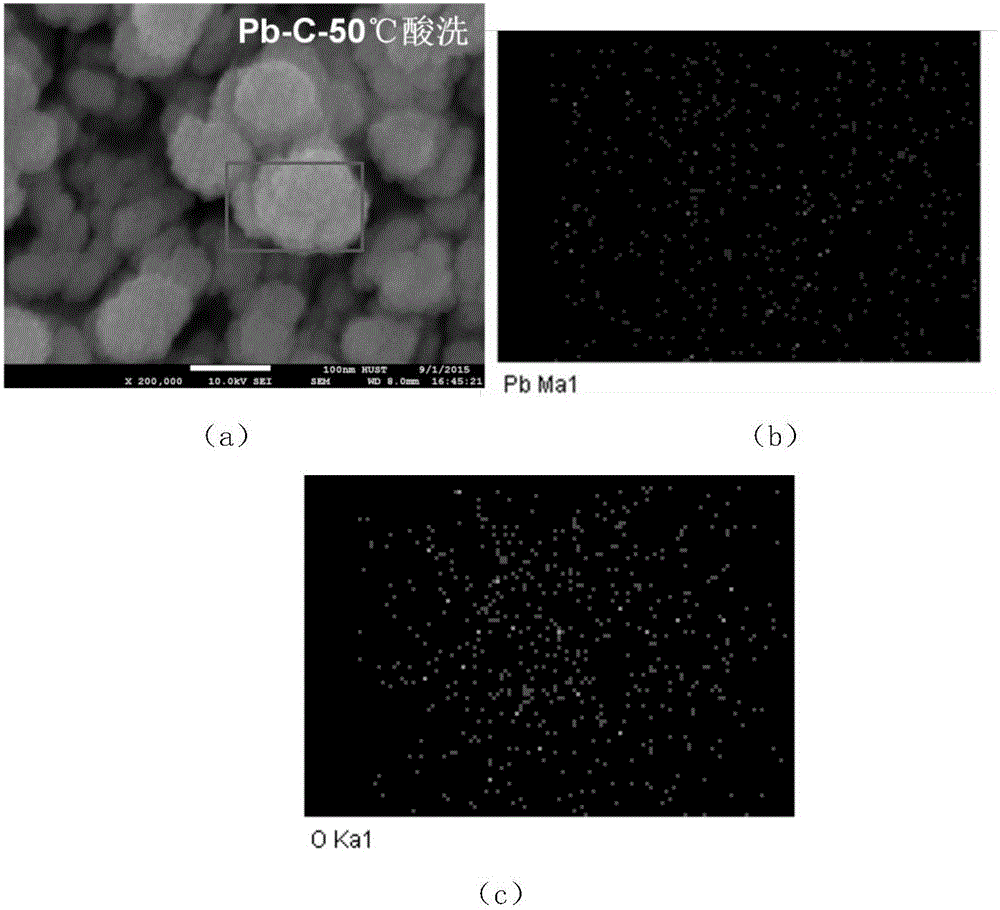

[0052] (3) The lead oxide-carbon composite obtained in step (2) is fully washed by adding 100ml of hydrochloric acid solution with a hydrogen ion content of 5M at 50°C, rinsed until the pH value is neutral, and dried to obtain the obtained lead oxide-carbon composites.

[0053] The specific steps of full washing are as follows: use magnetic stirring for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com