Multifunctional nano-composite sewage purification film and preparation method and application thereof

A sewage purification and nanocomposite technology, applied in chemical instruments and methods, energy wastewater treatment, water/sewage treatment, etc., can solve the problem of underutilization of light energy, and achieve the goals of avoiding loss, improving utilization rate, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of photothermal evaporation film

[0035] According to the formulation requirements, HAuCl 4 The solution is added to boiling deionized water, stirred for 1 minute, and then trisodium citrate solution is added, and then stirred continuously for 20 minutes to obtain nano-gold particles with a particle diameter of 10-100 nm, and then the prepared gold solution is centrifugally concentrated. Use anodic aluminum oxide AAO as the base film, place it on a suction filtration device, pour 25ml of concentrated gold solution into it, and use an air pump to carry out vacuum filtration until it is drained.

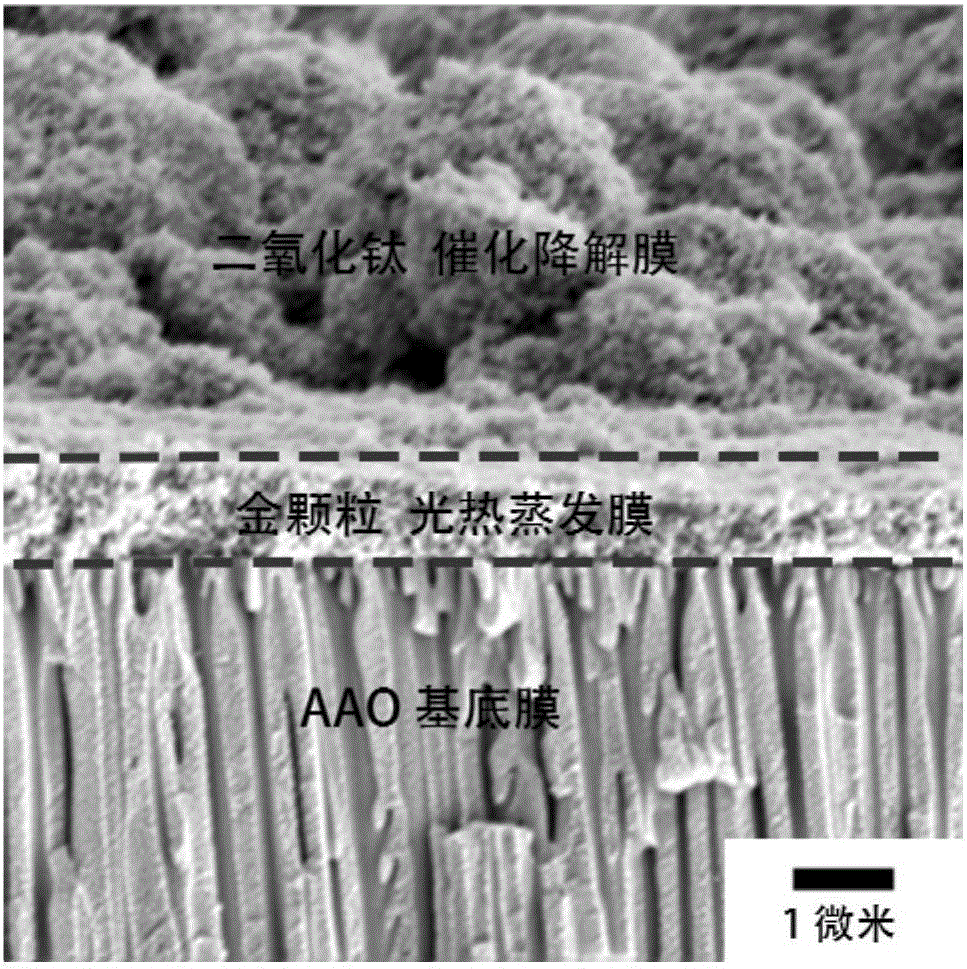

[0036] (2) Preparation of catalytic degradation membrane

[0037] On the basis of the previous step, continue to pour 1ml of titanium dioxide solution (particle size is ~ 25nm), carry out decompression suction filtration, then dry naturally to get such figure 1 TiO shown 2 -Au-AAO system nano-multifunctional sewage purification film.

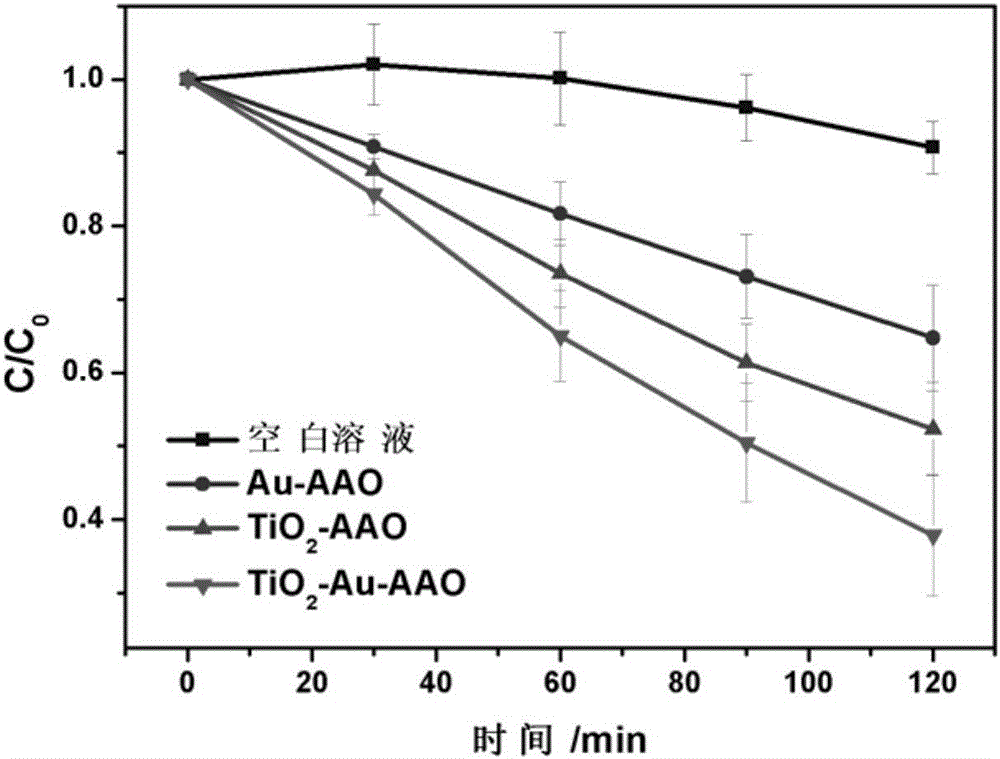

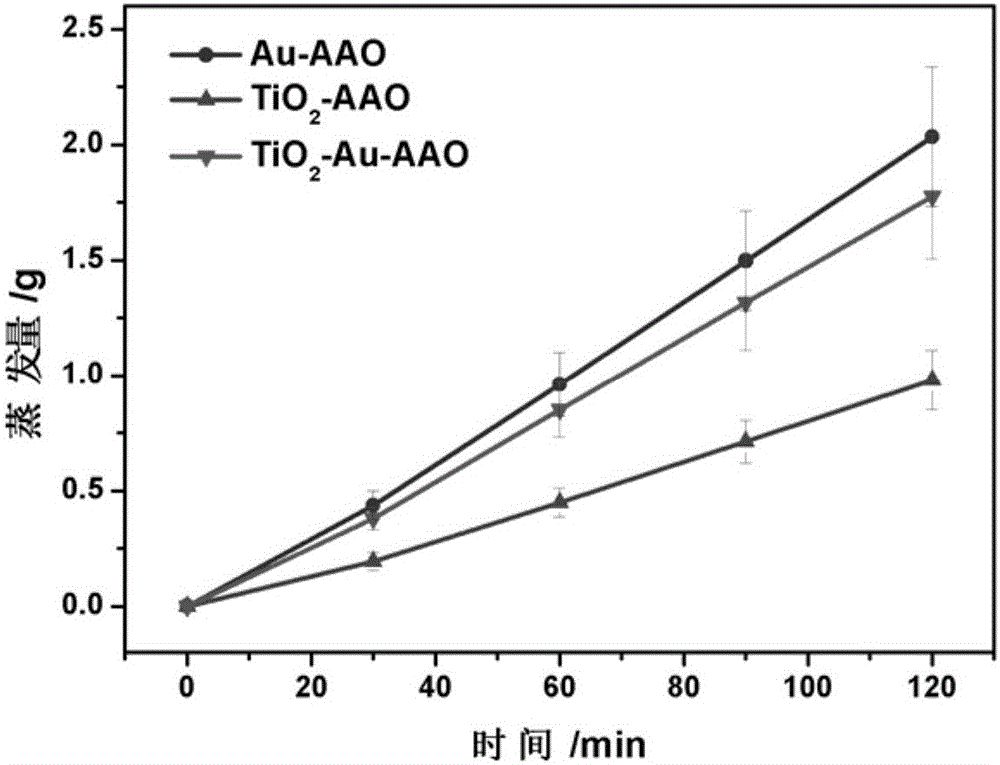

[0038] (3) Purify sewa...

Embodiment 2

[0043] A novel multifunctional nanocomposite sewage purification membrane and a preparation method thereof, the method comprising the following steps:

[0044] (1) Preparation of photothermal evaporation film: Anodic aluminum oxide AAO film with a certain porous nanostructure is used as a substrate, and a layer of nano-silver particles with photothermal conversion characteristics is deposited on the substrate template to prepare a photothermal evaporation film. Specifically: uniformly disperse spherical silver particles with a particle size of 1-50nm having photothermal conversion characteristics into water to obtain a solution with a weight concentration of 1%-30%, and deposit it on the AAO basement film by vacuum filtration A layer of silver particle thin film is obtained photothermal evaporation film.

[0045] (2) Preparation of catalytic degradation film: on the basis of the above-mentioned photothermal evaporation film, continue to deposit titanium dioxide particles with ...

Embodiment 3

[0048] The base film with a certain porous structure is a glass fiber filter membrane; the material with photothermal conversion characteristics is gold particles; the nano photocatalyst material with catalytic degradation performance is nano zinc oxide particles; photothermal evaporation The preparation of the film is made by the coating process: uniformly disperse the gold particles with light-to-heat conversion properties into water (weight concentration is 1%-30%), and form a light-heat on the surface of the glass fiber filter membrane through a controllable spin coating device. Evaporation film: on the basis of the above-mentioned photothermal evaporation film, spherical titanium dioxide particles with a particle size of 20nm having catalytic degradation properties are uniformly dispersed in water (weight concentration is 1%-30%), and continue to pass through a controllable spin coating device On the basis of the photothermal evaporation film, a layer of nanometer zinc oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com