Method for preparing modified white carbon black

A white carbon black and modified technology, applied in the direction of fibrous filler, dyed low molecular organic compound treatment, dyed high molecular organic compound treatment, etc. Carbon black and coupling agent bond energy, complex process operability and other problems, to achieve the effect of low price, good dispersion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of modified white carbon black, comprising the steps of:

[0027] Step 1: Add white carbon black to the reaction kettle, vacuumize, heat to 130-150°C, and stir for 2-3 hours;

[0028] Step 2: Using an inert gas to raise the pressure to 4-6MPa, keep the temperature constant, and shear for 1-1.5 hours; and

[0029] Step 3: Spray the modifying agent, raise the temperature to 150-165°C, vacuumize and stir at the same time, react for 1-2 hours, dry and discharge.

[0030] (1) Source of material

[0031] Silica Rhodia

[0032] Modifier bis(triethoxysilylpropyl)tetrasulfide Degussa

[0033] Modifier γ-(2,3-Glycidoxy)propyltrimethoxysilane Shanghai Jingrong Biotechnology Co., Ltd.

[0034] Modifier Pentaerythritol Jinan Century Tongda Chemical Co., Ltd.

[0035] Rubber solution polystyrene butadiene rubber SSBR2557S Dushanzi Petrochemical Branch

[0036] Other additives are commonly used additives in the rubber industry.

[0037] (2) Analysis method ...

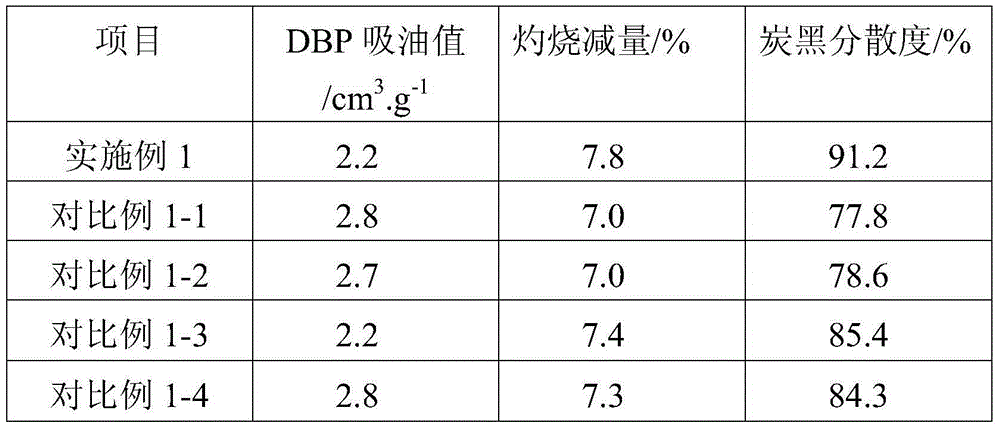

Embodiment 1

[0043] (1) Add 1000 grams of white carbon black into the grafting reactor, vacuumize, stir (speed 50r / min), heat to 135°C, and activate the white carbon black structure for 2 hours.

[0044] (2) Use inert gas to raise the pressure to 4MPa, keep the temperature at 140°C, and forcefully shear (shear rate 950r / min), and dissociate the structure for 1 hour.

[0045] (3) 80 grams of bis(triethoxysilylpropyl) tetrasulfide was sprayed slowly and uniformly in the form of a spray, stirred (speed 90r / min), heated to 155°C, and vacuumed at the same time, and the grafting reaction was carried out for 1.5 hours .

[0046] (4) After drying and cooling, graft-modified white carbon black is obtained.

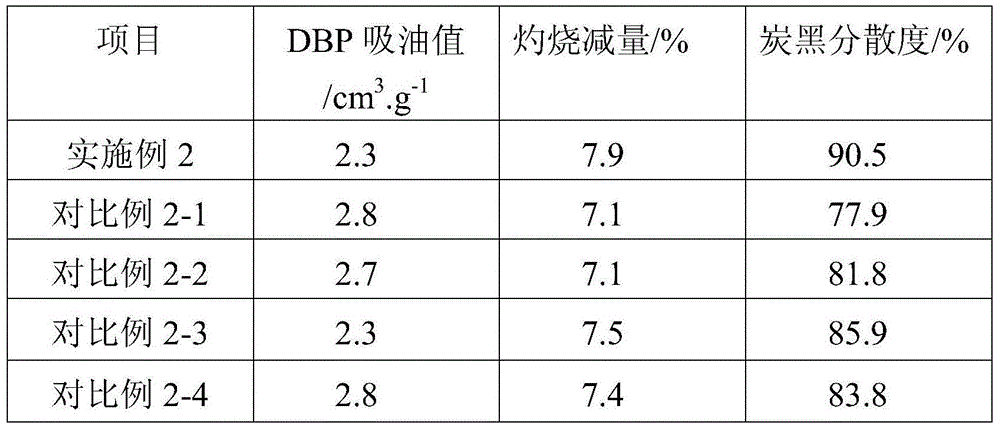

Embodiment 2

[0059] (1) Add 1000 grams of white carbon black into the grafting reactor, vacuumize, stir (speed 60r / min), heat to 135°C, and activate the white carbon black structure for 2 hours.

[0060] (2) Use inert gas to increase the pressure to 4MPa, keep the temperature at 140°C, and forcefully shear (shear rate 1100r / min), dissociate the structure for 1.5 hours.

[0061] (3) 120 grams of γ-(2,3-glycidyloxy)propyltrimethoxysilane was sprayed slowly and uniformly in the form of a spray, stirred (speed 90r / min), heated to 155°C, and vacuumed at the same time, The grafting reaction was carried out for 1.5 hours.

[0062] (4) Drying and cooling to obtain graft modified white carbon black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com