Composition, preparation method and application for improving pearlescent effect of pearlescent pigment

A pearlescent pigment and composition technology, which is applied to the wet preparation of dyed pigments, inorganic pigment processing, chemical instruments and methods, etc. Low equipment requirements, simple preparation method, and improved effect of pearlescent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

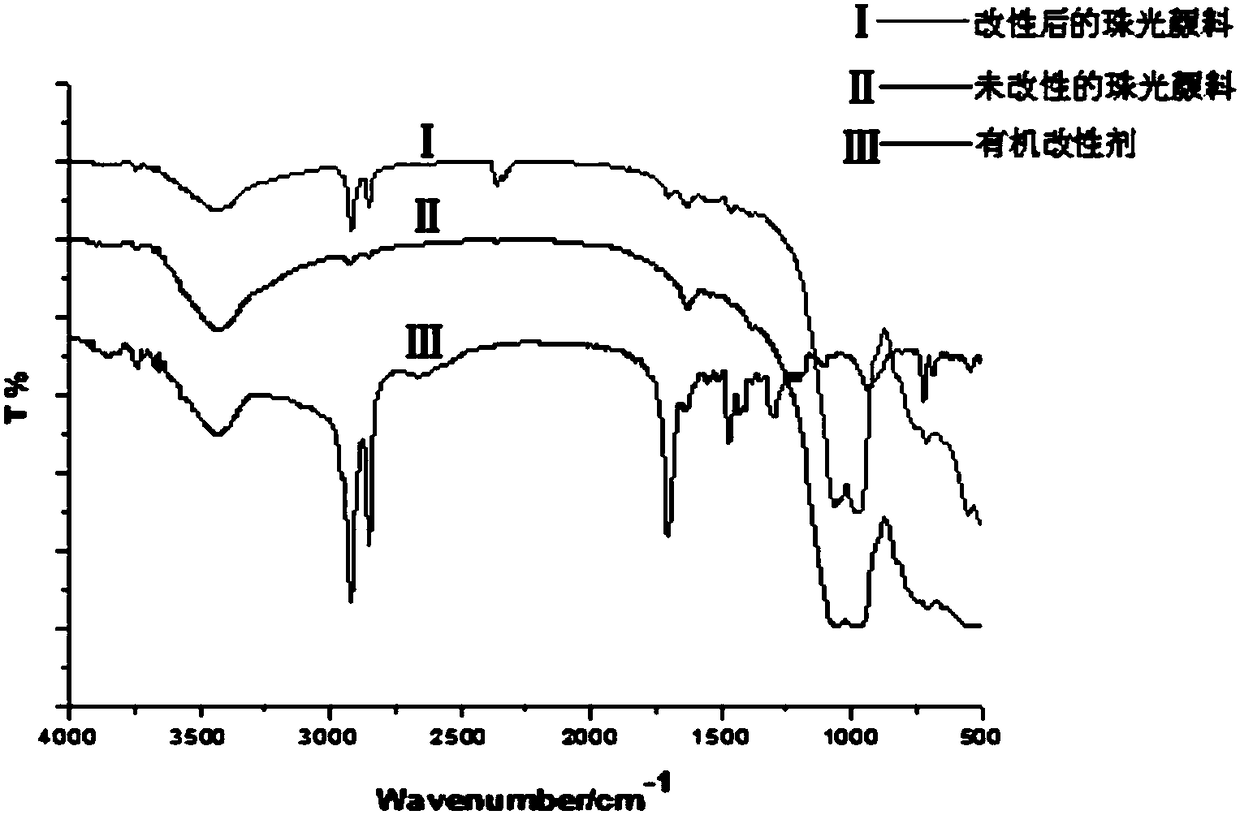

Method used

Image

Examples

Embodiment 1

[0027] Weigh 60g of golden yellow mica titanium pearlescent pigment, put it in a 500ml three-neck flask, add 180ml of absolute ethanol, stir and disperse in a water bath and heat up to 70°C, wherein the stirring speed is 800r / min, to obtain the first product 1; add 7.5g aqueous solution of silica clay additive (add 2.4g additive to 60ml deionized water, heat and stir to dissolve evenly, adjust pH=4 with glacial acetic acid), stir in water bath at 70°C for 0.5h to obtain the second product 1; slowly drop Add 0.5g of polydimethylsiloxane and 1.2g of stearic acid ethanol solution (1.2g of stearic acid is added to 60ml of absolute ethanol and heated to make it fully dissolved), and continue to stir at a constant temperature for 2h to obtain the third product 1; Product 1 was filtered under reduced pressure, the filter cake was dried at 60°C under normal pressure for 38 hours, and sieved with a 100-mesh sieve to obtain Product 1.

Embodiment 2

[0029] Weigh 55g of golden yellow mica titanium pearlescent pigment, place in a 500ml three-necked flask, stir to obtain the first product 2; add 4.0g of an aqueous solution of silica clay additive (2.2g of additive is added to 185ml of deionized water, heat and stir evenly and use Hydrochloric acid to adjust pH=3), stirring in a constant temperature water bath at 80°C for 0.5h to obtain the second product 2; add 2.0g titanate ethanol solution and 1.8g stearic acid ethanol solution, continue stirring for 1.5h, and stir under cooling for 20min to obtain the third product 2. The third product 2 was filtered under reduced pressure, and the filter cake was vacuum-dried at 120° C. for 1 hour, and sieved with a 150-mesh sieve to obtain product 2.

Embodiment 3

[0031] Weigh 15g of golden yellow mica titanium pearlescent pigment, place it in a 250ml three-necked flask, and stir to obtain the first product 3; add 1.0g of silica clay additive aqueous solution (1.0g of additive is added to 50ml of deionized water, and the pH is adjusted with glacial acetic acid =4 heated and stirred evenly), the feed liquid was placed in a water bath at a constant temperature of 90° C. and stirred for 1.5 h to obtain the second product 3; then 0.5 g of cetyltrimethylammonium bromide and 0.5 g of stearic acid ethanol solution (0.5 Add 20 ml of absolute ethanol to 1 g of stearic acid), continue to stir for 1 h to obtain the third product 3; filter the third product 3 under reduced pressure, dry the filter cake at 70°C under normal pressure for 30 h, and sieve with a 150-mesh sieve to obtain Product 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com