A method for preparing algae powder by drying cyanobacteria without peculiar smell

A technology with no peculiar smell and cyanobacteria, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as polluting the atmospheric environment and reducing the quality of algae powder, so as to reduce losses and reduce the production of cyanobacteria odorous molecules. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In order to obtain 1 ton of algae powder with a moisture content of 7%, the algae mud with a moisture content of 60%, 70%, 80%, and 90% were dried at a drying temperature of 280°C. After testing, it was found that the consumed The algae mud is 2.325t, 3.1t, 4.65t, 9.33t, the evaporated water is 1.325t, 2.1t, 3.65t, 8.33t, the material residence time is 6s, 15s, 25s, 50s, and the protein content is 48%. . After treatment, the measured odor concentration is 260, 950, 1200, 2000, and the tail gas is discharged through the 30m height exhaust pipe, which meets the GB14554-93 "Emission Standard of Odor Pollutants".

Embodiment 2

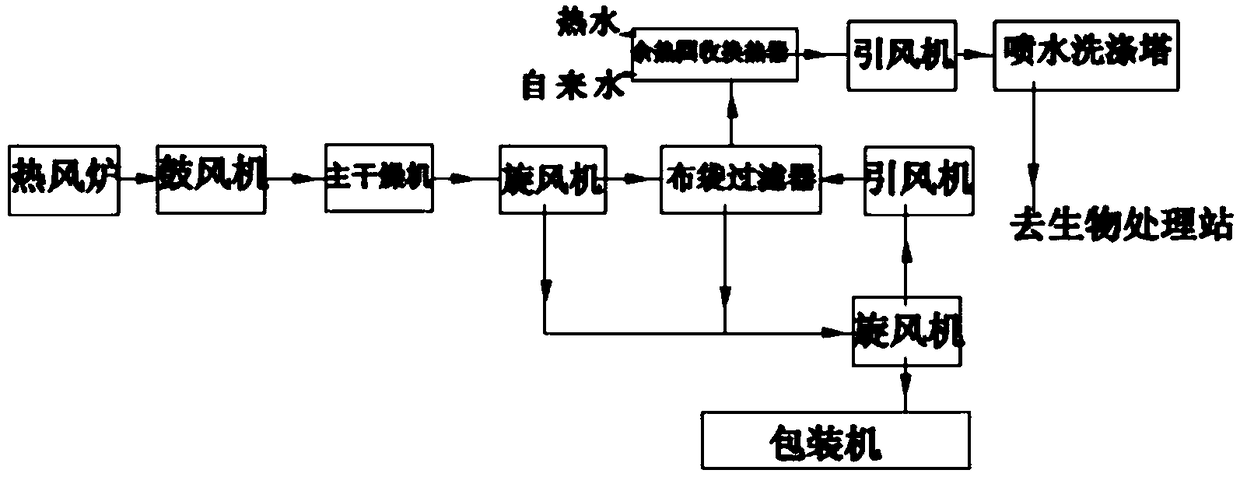

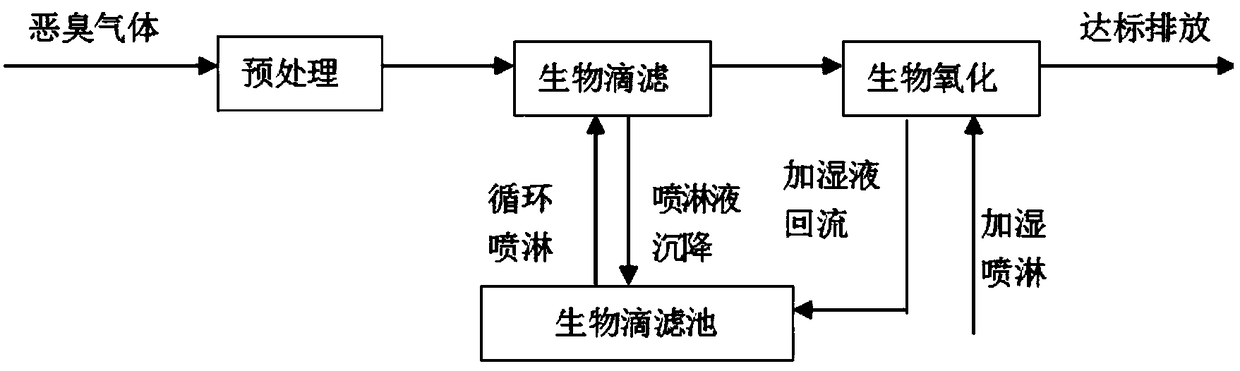

[0035] 10 tons of blue-green algae materials with a moisture content of 85% are pumped into the drying main machine for drying, and the hot flue gas is sent into the main machine by the blower. The drying temperature is set at 260 ° C, and the blue-green algae is dried, heat-transferred, and mass-transferred in it. , and finally, after being collected and dedusted by the first-stage cyclone fan and bag filter, the material enters the material cooling and packaging system through the closed fan, and the tail gas generated enters the biological deodorization system for treatment.

[0036] By setting the residence time of the material to be 30s, the moisture content is 8%, the protein content is 40%, and the ash content is 30% through testing the dried material.

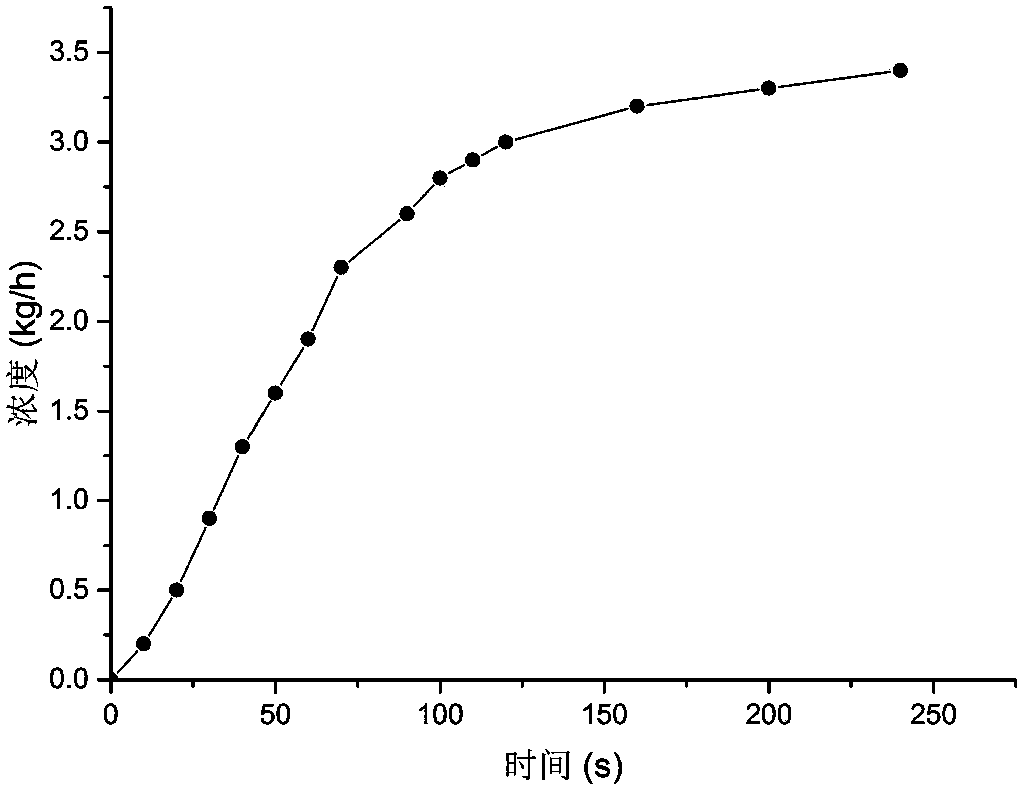

[0037] For the tail gas measurement after drying, the dimethyl disulfide produced is taken as the detection item, and the concentration is 0.5kg / h in the 30m exhaust pipe. The gas emission standard complies with GB14554-...

Embodiment 3

[0039] Similarly, 10 tons of cyanobacteria with a moisture content of 85% were dried, the drying temperature was set at 240°C, and the material residence time was set at 100s. By testing the dried material, the moisture content was 10%, and the protein content was 25%. %, the ash content is 40%.

[0040] The tail gas produced after drying is also measured with dimethyl disulfide as the detection item in a 30m exhaust pipe. The concentration is 1.9kg / h, and the gas emission does not meet the GB14554-93 "Emission Standard of Odor Pollutants".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com