Method for preparing polytetrafluoroethylene (PTFE) nanofiber porous membrane by virtue of PEO template scarification method

A polytetrafluoroethylene and nanofiber technology, used in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of unfavorable product performance, defects, high viscosity, and achieve excellent thermal stability, excellent chemical resistance, The effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

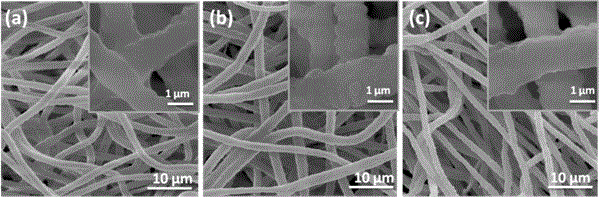

[0069] A PTFE nanofiber porous membrane prepared by the PEO template sacrifice method, wherein the mass ratio of PEO to PTFE in the spinning mixture is 3:100, prepared by the following steps:

[0070] (1) Dissolve PEO powder B-1 in water at 40 °C, stir and mix for 3 hours to prepare a PEO aqueous solution with a mass fraction of 4 wt%, cool to room temperature and there are no bubbles in the solution, then add PTFE emulsion A-1, and stir Mix for 1 hour to obtain spinning mixture;

[0071] (2) Spin the spinning mixture obtained in step (1) using electrospinning technology, the voltage during the electrospinning is 20kV, the distance from the spinning nozzle to the opposite electrode collecting substrate is 20cm, and the spinning The flow rate is 0.002mm / s;

[0072] (3) Collect the PEO / PTFE nascent composite nanofiber membrane obtained after electrospinning in step (2), then place it in an oven and dry it at 70°C for 1 hour;

[0073] (4) Heat the dried composite nanofiber memb...

Embodiment 2

[0076] A PTFE nanofiber porous membrane, which is prepared by using the PEO template sacrifice method, wherein the mass ratio of PEO to PTFE in the spinning mixture is 3:100, and the preparation method is the same as that of Example 1, except that step (4): The composite nanofiber membrane dried in step (3) was heated at 380 °C for 10 min to decompose and remove PEO, and at the same time, PTFE nanoparticles were melt-bonded, and finally a continuous PTFE nanofiber porous membrane was obtained.

[0077] Performance characterization: the tensile strength of the PTFE nanofiber porous membrane is 14.52MPa, the elastic modulus is 65.89MPa, and the elongation at break is 658.40%; the PTFE nanofiber porous membrane is placed at 7.14 mol / L -1 h 2 SO 4 After being treated at 100 °C for 12 h, the tensile strength was 14.46 MPa, the elastic modulus was 66.78 MPa, and the elongation at break was 642.12 %; the PTFE nanofiber porous membrane was placed in a 6 mol / L -1 After being treated...

Embodiment 3

[0080] A PTFE nanofiber porous membrane, which is prepared by using the PEO template sacrifice method, wherein the mass ratio of PEO to PTFE in the spinning mixture is 3:100, and the preparation method is the same as that of Example 1, except that step (4): The composite nanofiber membrane dried in step (3) was heated at 400 °C for 10 min to decompose and remove PEO, and at the same time, PTFE nanoparticles were melt-bonded, and finally a continuous PTFE nanofiber porous membrane was obtained.

[0081] Performance characterization: the tensile strength of the PTFE nanofiber porous membrane is 11.21 MPa, the elastic modulus is 66.13MPa, and the elongation at break is 545.31%; the PTFE nanofiber porous membrane is placed at 7.14 mol / L -1 h 2 SO 4 After being treated at 100 °C for 12 h, the tensile strength was 10.97 MPa, the elastic modulus was 67.26 MPa, and the elongation at break was 529.33%; the PTFE nanofiber porous membrane was placed in a 6 mol / L -1 After being treated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com