Optical fingerprint recognition device and forming method thereof

A fingerprint identification and optical technology, applied in the field of image processing, can solve the problems of long optical path, low output, inability to apply portable electronic devices, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

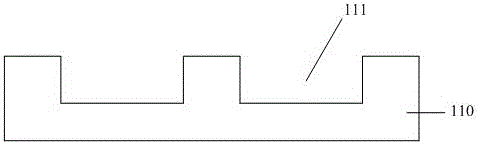

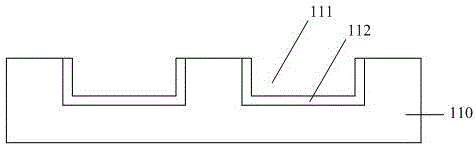

[0027] Figure 1-Figure 10 It is a schematic diagram of the process of forming the optical fingerprint identification device according to Embodiment 1 of the present invention.

[0028] Such as Figure 1-Figure 3 As shown, a silicon substrate 110 is provided, and a groove array 111 is formed on the silicon substrate 110 . Preferably, a silicon dioxide layer, silicon nitride layer or titanium layer 112 is formed on the groove array 111 as a stop layer for subsequent etching.

[0029] Such as Figure 4-Figure 6 As shown, a light-transmitting substrate 120 and an image sensor chip 130 are provided. After bonding the light-transmitting substrate 120 and the image sensor chip 130, the backside of the image sensor chip 130 is thinned, and then the light-transmitting substrate 120 is formed on the light-transmitting substrate 120 by a gradual light flux lithography method. A lens array 150 corresponding to a photosensitive array (not shown) of the image sensor chip 130 is formed. ...

Embodiment 2

[0034] Figure 11-Figure 18 It is a schematic diagram of the process of the forming method of the optical fingerprint identification device according to the second embodiment of the present invention.

[0035] Such as Figure 11 As shown, a silicon substrate 210 is provided. Preferably, a silicon dioxide layer, a silicon nitride layer or a titanium layer 211 is formed on the silicon substrate 210 as a stop layer for subsequent etching.

[0036] Such as Figure 12-Figure 14 As shown, a light-transmitting substrate 220 and an image sensor chip 230 are provided. After bonding the light-transmitting substrate 220 and the image sensor chip 230, the backside of the image sensor chip 230 is thinned, and then the light-transmitting substrate 220 is formed on the light-transmitting substrate 220 by a gradual light flux lithography method. A lens array 250 corresponding to a photosensitive array (not shown) of the image sensor chip 230 is formed. Preferably, the protective film 251 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com