Preparation method of co-doped graphene gel by bonding of metal and nitrogen

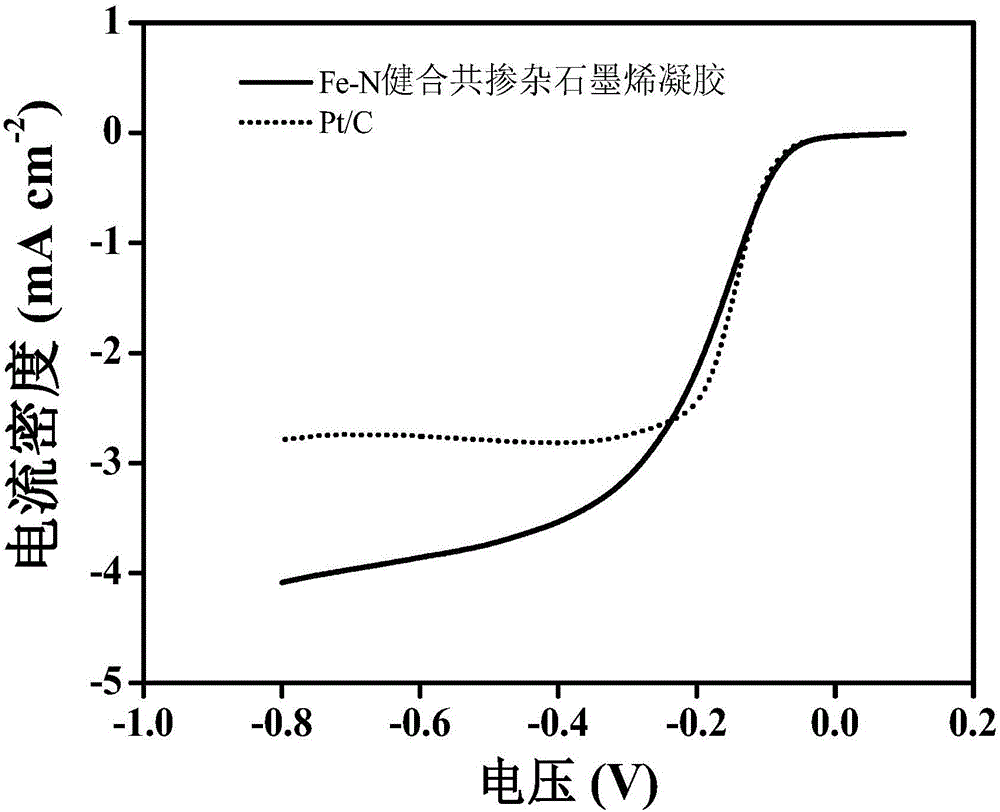

A graphene gel and co-doping technology, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems that hinder the commercialization of fuel cells, the scarcity of Pt resources, and the high cost of batteries, and achieve excellent electrocatalytic performance and methanol resistance Good performance and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

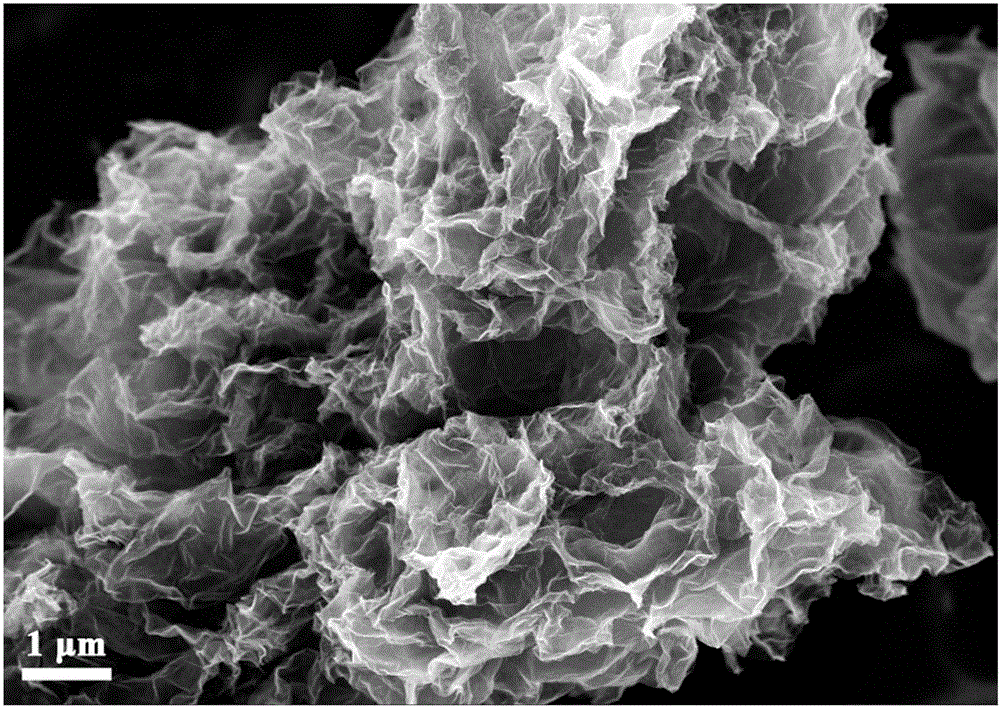

[0026] (1) Using the improved Hummers method, add 120mL of concentrated sulfuric acid and 13.3mL of concentrated phosphoric acid to a 500mL container in turn, stir, slowly heat up to 50°C in a water bath, add 1g of graphite powder, 6g of potassium permanganate, stir for 12h, and the solution Pour it onto ice cubes containing 10 mL of hydrogen peroxide solution, stir and cool to room temperature, and filter unreacted solids. Centrifugal washing to neutrality, drying to obtain graphene oxide;

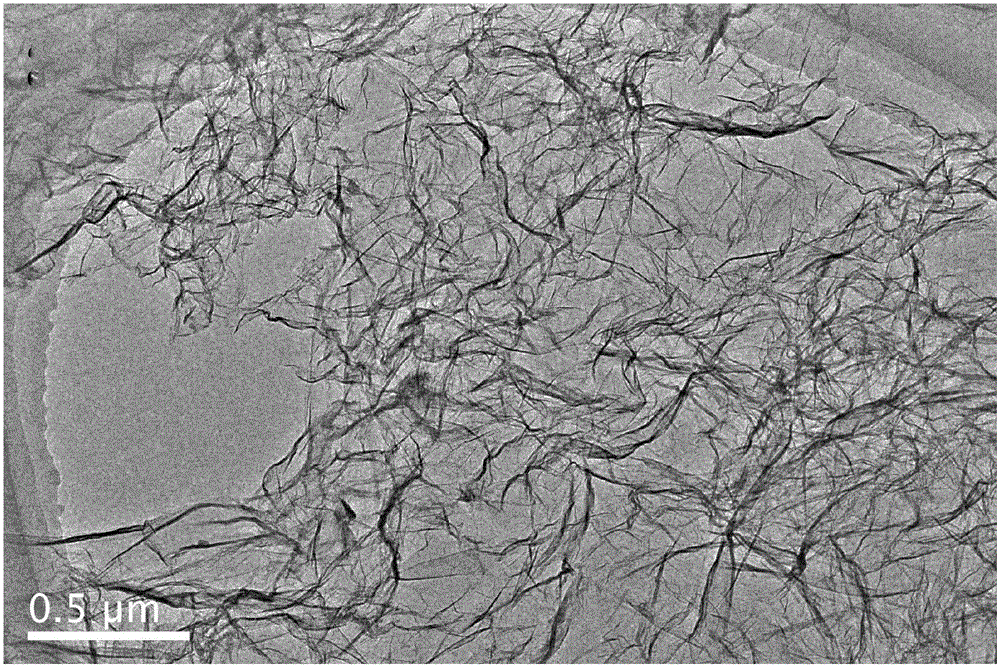

[0027] (2) Weigh 0.15g of GO, add 15mL of double distilled water, sonicate for 2min, add 1mL of formaldehyde, 0.35g of melamine, 40mg of ferric nitrate, stir gently; at 120°C, hydrothermally react for 12h. The resulting solid is freeze-dried to obtain a xerogel supported by a cross-linking agent;

[0028] (3) Heat the xerogel to 300°C at a heating rate of 5°C / min in a tube furnace under an argon atmosphere, then raise the temperature to 550°C at a heating rate of 10°C / min, and keep it wa...

Embodiment 2

[0030] (1) The preparation method of graphene oxide is the same as embodiment 1.

[0031] (2) Weigh 0.015g GO, add 15mL of double distilled water, sonicate for 2min, add 1mL of formaldehyde, 0.15g of phenol, 40mg of cobalt nitrate, stir gently; at 140°C, hydrothermal reaction for 12h. The obtained solid is freeze-dried to obtain a xerogel supported by a cross-linking agent;

[0032] (3) Heat the xerogel to 300°C at a heating rate of 5°C / min in a tube furnace under an argon atmosphere, then raise the temperature to 650°C at a heating rate of 10°C / min, and keep it warm for 6 hours. Remove the product after the temperature has dropped to room temperature.

Embodiment 3

[0034] (1) The preparation method of graphene oxide is the same as embodiment 1.

[0035] (2) Weigh 0.15g GO, add 15mL double-distilled water, sonicate for 2min, add 2mL formaldehyde, 0.7g urea, 40mg nickel nitrate, stir gently; at 160°C, hydrothermal reaction for 12h. drying the obtained solid at 80°C to obtain a xerogel supported by a crosslinking agent;

[0036] (3) Heat the dry gel up to 300°C at a heating rate of 5°C / min in a tube furnace under a nitrogen atmosphere, then raise the temperature to 750°C at a heating rate of 10°C / min, and keep it warm for 6 hours, then wait for Remove the product after the temperature has dropped to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com