Method for preparing composite shellfish toxin adsorbent by coating porous shell particles with chitosan

A technology of shell particles and shellfish toxins, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of unavailable aquatic raw materials, high use costs, and high prices, and reduce preparation costs and use The effect of cost, strong absorption capacity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

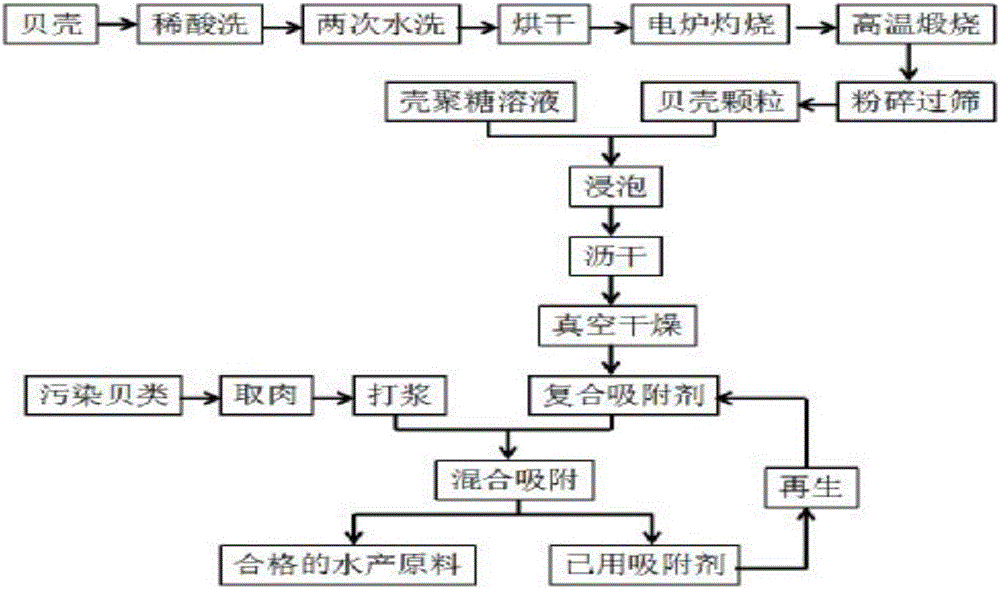

Method used

Image

Examples

Embodiment 1

[0023] Weigh the oyster shell, wash the surface with 0.5% dilute hydrochloric acid, rinse it with clean water, dry it with hot air at 100°C, burn it on an electric furnace for 30 minutes, then place it in a muffle furnace at 600°C for 2 hours, cool it, crush it, and pass it for 20 minutes. Mesh sieve to prepare shell particles. Weigh chitosan, dissolve in 1% glacial acetic acid solution, prepare 1% chitosan solution, mix shell particles with chitosan solution according to the ratio of material to liquid 1:5, stir well, soak for 60min, and separate the shells Granules, drain the solution, vacuum degree ≤ 0.10MPa, vacuum drying at 60°C for 4 hours, to obtain a composite adsorbent. Shell the scallops contaminated with paralytic shellfish toxin and take the meat, add 3 times the volume of water, make a pulp, pass through a 200-mesh sieve, put it in a hot and cold cylinder with stirring, add 0.05% of the slurry mass Composite adsorbent, room temperature Adsorption treatment was ca...

Embodiment 2

[0025] Weigh the scallop shell, wash the surface with 0.2% dilute sulfuric acid by volume, rinse it with clean water, dry it with hot air at 80°C, burn it on an electric furnace for 20 minutes, and then calcinate it in a muffle furnace at 700°C for 2 hours. After cooling, crush it. Pass through a 20-mesh sieve to prepare shell particles. Weigh chitosan, dissolve in 1% glacial acetic acid solution, prepare 1.5% chitosan solution, mix shell particles with chitosan solution according to the ratio of material to liquid 1:3, stir well, soak for 40min, and separate shells Granules, drain the solution, vacuum degree ≤ 0.10MPa, vacuum drying at 65°C for 3 hours, to obtain a composite adsorbent. Shell the scallops polluted with paralytic shellfish toxin, add 4 times the volume of water, make a pulp, pass through a 200-mesh sieve, place in a hot and cold cylinder with stirring, add 0.1% of the slurry mass Composite adsorbent, room temperature Adsorption treatment was carried out under ...

Embodiment 3

[0027] Weigh the clam shell, wash the surface with 0.3% dilute acetic acid, rinse it with clean water, dry it with hot air at 70°C, burn it on an electric furnace for 60 minutes, then place it in a muffle furnace at 600°C for 3 hours, cool it, crush it, and pass it for 20 minutes. Mesh sieve to prepare shell particles. Weigh chitosan, dissolve it in 1% glacial acetic acid solution, prepare 3% chitosan solution, mix shell particles with chitosan solution according to the ratio of solid to liquid 1:10, stir evenly, soak for 90min, and separate the shells Granules, drain the solution, vacuum degree ≤ 0.10MPa, vacuum drying at 70°C for 6 hours, to obtain a composite adsorbent. Shell the scallops contaminated with paralytic shellfish toxin, add 5 times the volume of water, make a slurry, pass through a 200-mesh sieve, place in a hot and cold cylinder with stirring, add 0.07% of the slurry mass Composite adsorbent, room temperature Adsorption treatment was carried out under stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com