Efficient and low-pollution phosphorous-slurry recycling method

A sludge phosphorus recovery and low pollution technology, applied in the field of phosphorus chemical industry, can solve the problems of difficult monitoring of equipment safety, reduced safety performance, and non-standard phosphorus content, etc., and achieve good recovery effect, low operating cost, and optimized process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

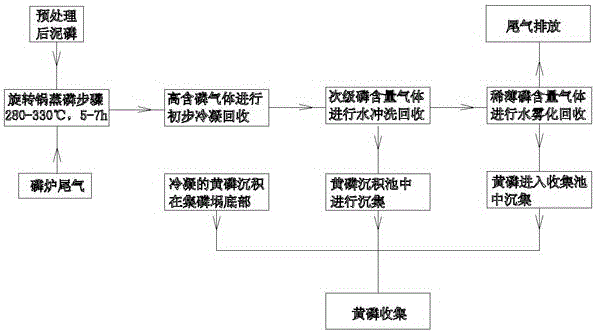

[0031] Such as figure 1 As shown, a kind of highly efficient and low-pollution mud phosphorus recovery method described in this embodiment comprises the following process steps:

[0032] ① Phosphorus steaming steps:

[0033] First, the mud phosphorus is sent to the transition tank by the mud water pump for pretreatment. The pretreatment is to separate the mud phosphorus mixed with water in the sealed transition tank to remove the easily separated water and reduce the Energy consumption in the dry steaming link; then put the mud phosphorus into the rotary pot, use the exhaust gas of the phosphorus furnace to heat outside the rotary pot, heat to 280-330°C and keep it for 5-7 hours, the yellow phosphorus in the mud phosphorus will gradually volatilize into Phosphorus vapor, phosphorus vapor enters the condensation recovery process through the pipeline;

[0034] ②Condensation recovery steps:

[0035] Primary condensation recovery for high phosphorus-containing gases:

[0036] ...

Embodiment 2

[0042] A high-efficiency and low-pollution mud phosphorus recovery method described in this embodiment, its steps are basically the same as those described in Example 1, the difference is that in order to improve the safety performance of the atomization recovery step, an atomization tower is installed to adjust its internal The pressure regulating valve is used to open the pressure relief when the internal pressure of the atomization tower is too high to ensure the safety of the equipment.

Embodiment 3

[0044] A high-efficiency and low-pollution mud phosphorus recovery method described in this embodiment, its steps are basically the same as those described in Example 1, the difference is that in order to improve the recovery rate of phosphorus in the lower part of the atomization tower after condensation, a The cooling layer that increases the liquid stroke is used for the cooling of the gas phase material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com