Water-borne wood paint resin used outdoors and preparation method thereof

A water-based wood paint and resin technology, which is applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the surface properties of low surface energy (water resistance, oil resistance and stain resistance, can be extremely Low chemical resistance, difficult wetting, adhesion and aggregation, etc., to achieve good adhesion, improved anti-aging performance, excellent water repellency and even stain repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

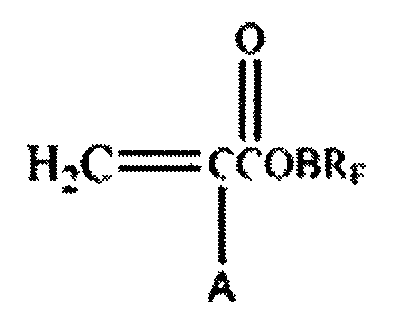

Method used

Image

Examples

Embodiment Construction

[0023] 1. Stir 30g of methyl methacrylate, 5.4g of butyl methacrylate, 2.3g of isobornyl methacrylate, 1.5g of OP-10, 1.5g of sodium dodecylsulfonate, and 130g of deionized water Pre-emulsification; after the emulsification is complete, add 40g of the pre-emulsion to the round bottom flask, react at 80°C until there is no reflux, and drop the remaining pre-emulsion within 1 hour; keep warm for 2 hours; 18.2g of methyl methacrylate, 3g of acrylic acid, acrylic acid 27.1 g of butyl ester, 2 g of ethyl acrylate, 28.7 g of 2-(perfluorohexyl) ethyl acrylate, and 2.3 g of hydroxypropyl acrylate are blended and added dropwise to the reaction solution within 2 hours; keep warm for 2 hours; cool down and add ammonia water Neutralize the pH to 7; filter to obtain the product.

[0024] 2. Put 1.2g of OP-10, 2.7g of sodium dodecylbenzenesulfonate, and 148g of deionized water into a round bottom flask, stir and heat up to 75°C; 3.1 g, 1.8 g of butyl methacrylate, and 2.5 g of 2-(perfluoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com