A method for strengthening the calcification of converter vanadium slag to extract vanadium

A converter vanadium slag and vanadium slag technology, applied in the field of metallurgy, can solve the problems of low vanadium leaching rate and reduced production efficiency in the calcification vanadium extraction process, and achieve the advantages of mature mechanical activation strengthening process, improved leaching rate, and improved oxidative roasting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

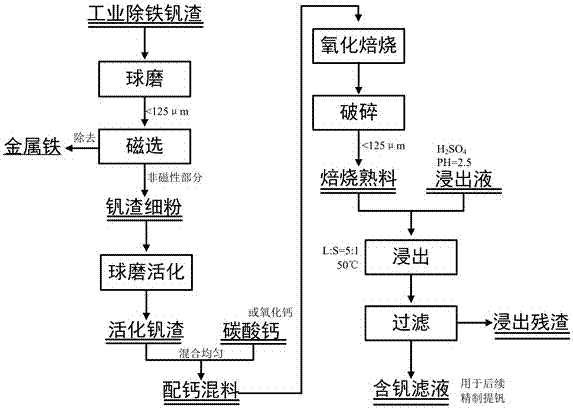

[0031] A method for strengthening the calcification of converter vanadium slag to extract vanadium, referring to figure 1 The shown technological process includes the following steps:

[0032] 1) The vanadium-containing slag after industrial iron selection is used as raw material, crushed and screened in a ball mill or pulverizer until the particle size is less than 125 microns, and then magnetically separated by a dry-type magnetic separator to obtain a vanadium slag fine powder. The vanadium slag fine powder particle size Distributed at 1.7-125 microns, the average particle size is 46 microns, and the specific surface area is about 0.2m 2 / g. .

[0033] 2) Put the fine powder of vanadium slag obtained in step 1) into a high-energy ball mill. According to the mass ratio of material to ball 5:1, the speed of the ball mill is 400rpm, and the ball mill is 80min to obtain activated vanadium slag. The particle size distribution of activated vanadium slag is 0.04-45 microns, the...

Embodiment 2 to 10

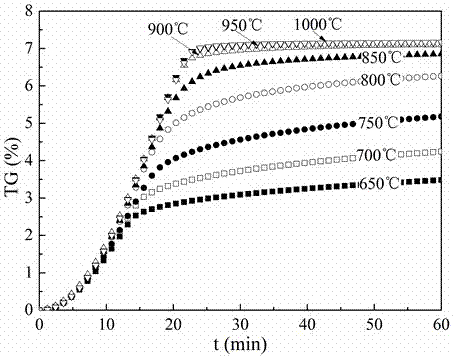

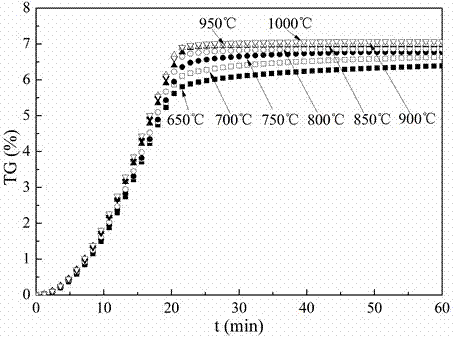

[0039] The same method as in Example 1 was adopted, except that the ball milling time in step 2) was different and the calcination temperature in step 4) was different. The ball milling and roasting parameters and leaching effects of Examples 2 to 10 are shown in Table 1 in detail. The thermogravimetric curves of isothermal oxidation roasting of unmilled vanadium slag fine powder mixed with calcium mixture and 80min ball milled activated vanadium slag mixed with calcium mixture are as follows figure 2 and image 3 shown.

[0040] Ball milling, roasting parameters and leaching rate of table 1 embodiment 2 to 10

[0041]

Ball milling time (min)

Calcination temperature (℃)

Roasting time (min)

Leaching rate (%)

Example 2

80

750

60

79.60

Example 3

80

850

60

86.32

Example 4

80

900

60

81.68

Example 5

40

800

60

91.25

Example 6

20

800

60

90.40

Example 7

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com