Method for preparing deodorizing bamboo pulp cellulose nonwoven fabrics through spun-bond mode

A technology of cellulose and cellulose content, applied in the direction of single-component cellulose rayon, wet spinning, non-woven fabrics, etc., can solve the problems of bamboo fiber without deodorization and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

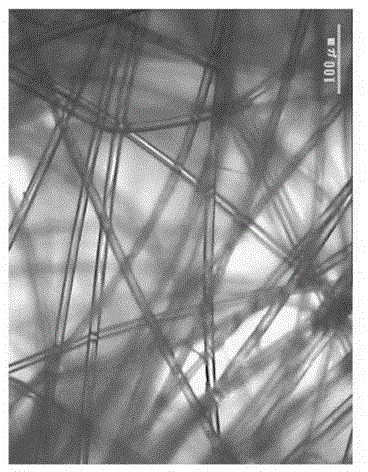

[0022] In order to further illustrate the production process and efficacy of the present invention, the illustrations and various test examples are hereby described in detail as follows:

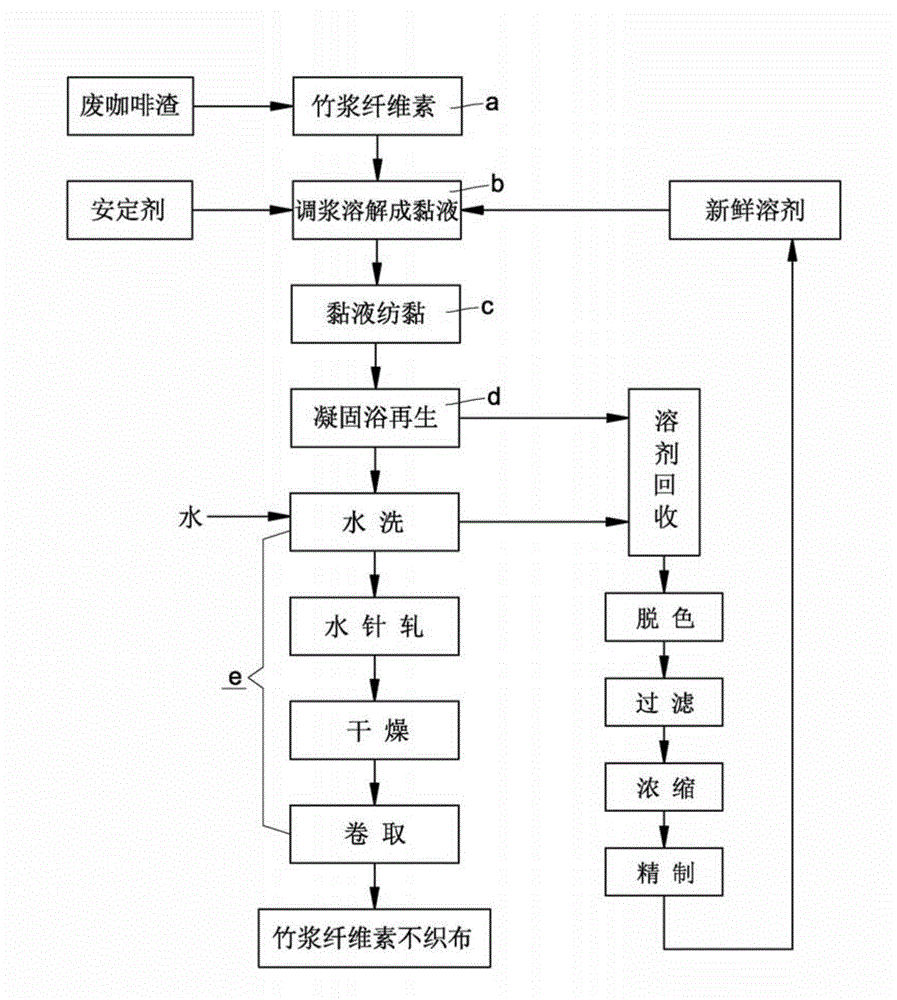

[0023] see Figure 1 to Figure 5 Shown, the present invention prepares the method for the bamboo pulp cellulose nonwoven fabric with deodorizing function with spun-bonded mode, and its step comprises:

[0024] a. Add waste coffee residue (Coffee residue) to bamboo pulp (Bamboo pulp) as a raw material; the waste coffee residue is first ground at a high speed into 500nm-900nm (nanometer) micro-particles and then added to bamboo pulp. The bamboo pulp is selected α-bamboo pulp cellulose with a cellulose content of more than 50%, the cellulose polymerization degree (degree ofpolymerization, referred to as DP) is between 350 and 750;

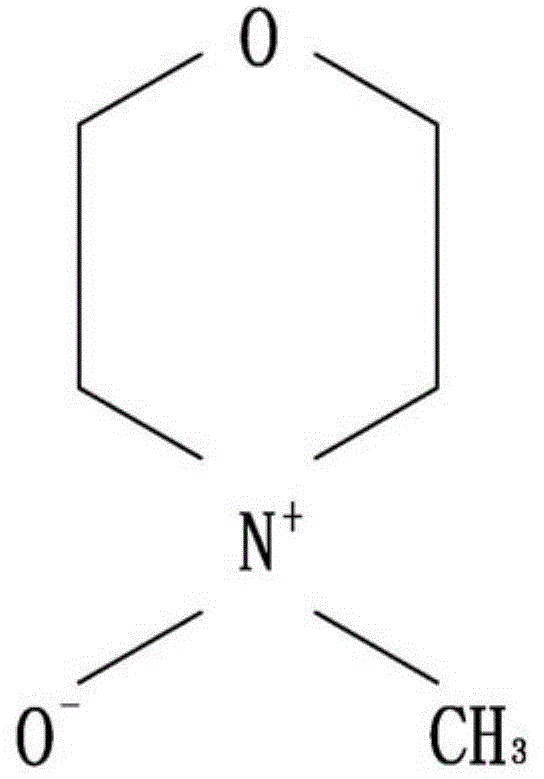

[0025]b. Add methylmorpholine N-oxide (N-methylmorpholine N-oxide, NMMO for short, its chemical structure is as follows figure 2 Shown) and phenyl oxazolam (1,3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base weigh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com