High-reliability environmental-friendly aluminium alloy power cable

A power cable and reliability technology, applied to power cables with shielding/conducting layers, insulated cables, cables, etc., can solve problems such as cable pollution, and achieve low release of harmful gases, low corrosion, and high visibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

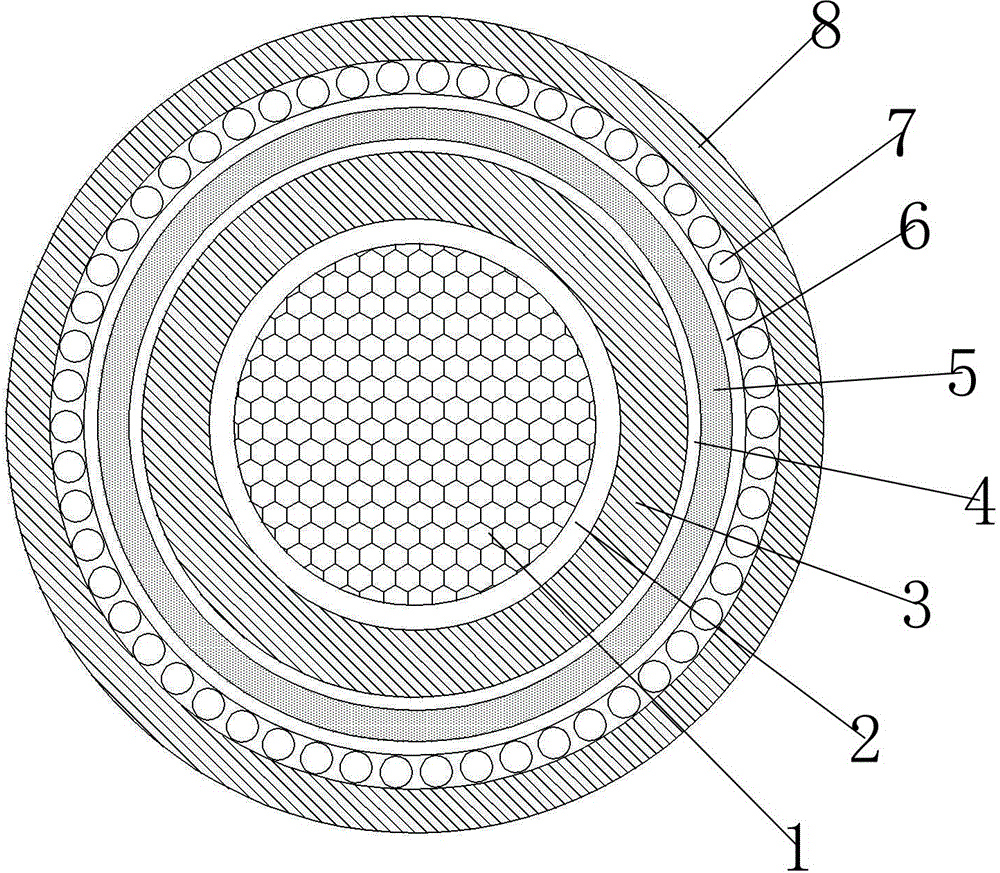

[0016] Embodiment 1: as figure 1 As shown, the high-reliability environment-friendly aluminum alloy power cable includes an 8030 aluminum alloy conductor 1, a polyimide tape wrapping layer 2 wrapped outside the 8030 aluminum alloy conductor 1, and an extruded polyimide tape wrapping layer The insulating layer 3 of the outer 2, the copper-plastic composite tape shielding the wrapping layer 4 wrapped outside the insulating layer 3, the filling layer 5 wrapping the copper-plastic composite tape shielding the wrapping layer 4, and the synthetic mica wrapped outside the filling layer 5 Wrapping layer 6 with inner lining, steel wire armor layer 7 wrapped with synthetic mica tape lining wrapping layer 6, outer sheath 9 extruded outside steel wire armor layer 7; filling layer is made of mesh PP filling rope and 3M 8882 elastic insulating waterproof resin composition. The weight ratio of mesh PP filling rope to 3M 8882 elastic insulating and waterproof resin is 5:4; 3M 8882 elastic in...

Embodiment 2

[0023] Embodiment 2: High-reliability environment-friendly aluminum alloy power cable, the structure is the same as Embodiment 1, the difference is that the cable material used for the insulating layer and the outer sheath is made by the following steps:

[0024] (1) Add 1.2 kg of diacetyl tartaric acid mono-diglycerides and 3 kg of cocoamine polyoxyethylene ether (AC-1203) to ten times the weight of pure water and stir evenly, then add nanometer yttrium aluminate with an average particle size of 40nm 1.5 kg, 4 kg of nano-silicon carbide with an average particle size of 40nm, and 4 kg of hydroxyapatite with an average particle size of 20um, mix well, oscillate ultrasonically for 100 minutes, and dry at 40-50°C;

[0025] (2) Mix 10 kg of 800-mesh light calcium carbonate, 16 kg of 1500-mesh dolomite powder, 20 kg of 2000-mesh magnesium hydroxide, and 2.5 kg of LD-B-1 aluminate coupling agent from Yangzhou Lida Resin Co., Ltd. Uniform;

[0026] (3) Heat the internal mixer to 90-...

Embodiment 3

[0028] Embodiment 3: High-reliability environment-friendly aluminum alloy power cable, the structure is the same as Embodiment 1, the difference is that the cable material used for the insulating layer and the outer sheath is made by the following steps:

[0029] (1) Add 1 kg of diacetyl tartaric acid mono-diglycerides and 2 kg of cocoamine polyoxyethylene ether (AC-1203) to ten times the weight of pure water and stir evenly, then add nanometer yttrium aluminate with an average particle size of 40nm 1 kg, 3 kg of nano-silicon carbide with an average particle size of 40nm, and 3 kg of hydroxyapatite with an average particle size of 20um, mix well, oscillate ultrasonically for 100 minutes, and dry at 40-50°C;

[0030] (2) 8 kg of light calcium carbonate of 800 mesh, 14 kg of dolomite powder of 1500 mesh, 18 kg of magnesium hydroxide of 2000 mesh, 2 kg of LD-B-1 aluminate coupling agent of Yangzhou Lida Resin Co., Ltd., mixed Uniform;

[0031] (3) Heat the internal mixer to 110-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com