Inverted blue light quantum-dot thin film electroluminescence device and manufacturing method thereof

A technology for electroluminescent devices and quantum dots to emit light, which can be used in the manufacture of semiconductor/solid-state devices, electric solid-state devices, electrical components, etc., and can solve problems such as restricting and restricting luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

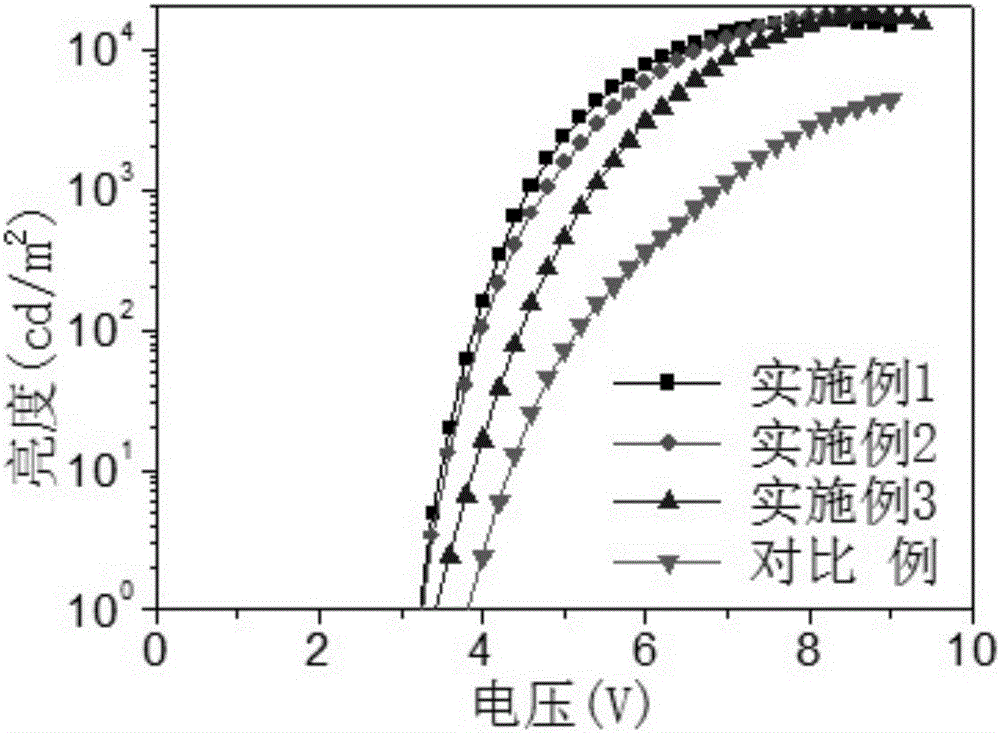

Embodiment 1

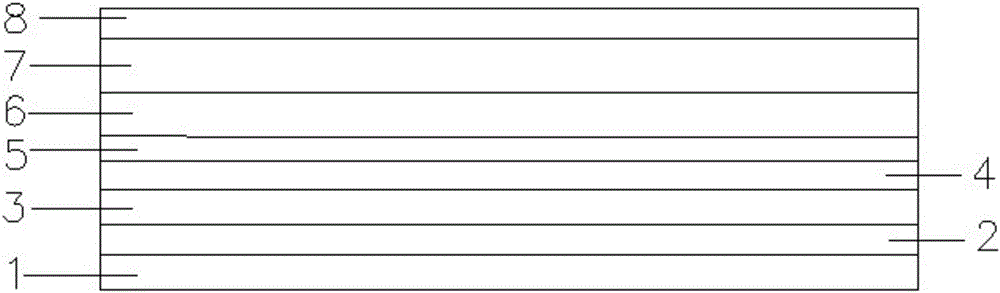

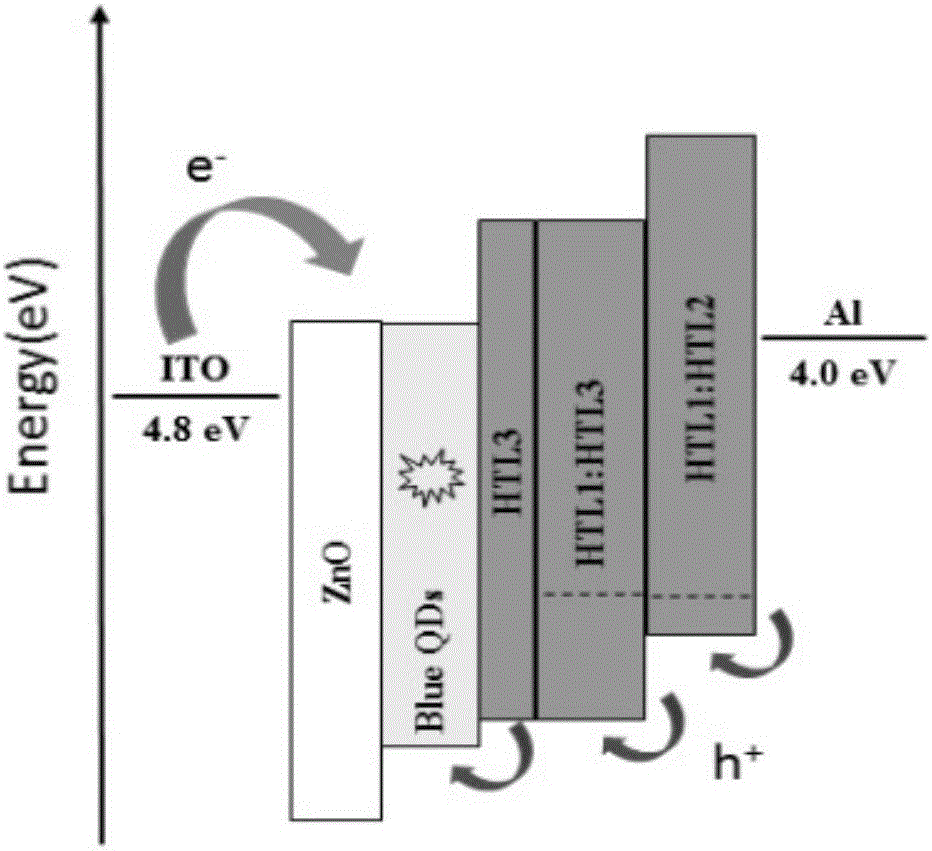

[0044] Substrate 1 was first ultrasonically treated with detergent, acetone, ethanol and isopropanol for 15 min each. Then a layer of ITO conductive film with a thickness of 150nm was sputtered on the substrate 1, and then UV-ozone was performed for 15 minutes. Next, the ZnO electron transport layer 3 was prepared in a glove box filled with nitrogen and extremely low in water and oxygen content by solution spin coating, using 20 mg / ml of ZnO nanoparticle ethanol solution at a speed of 1500 rpm (Resolutions per minute, rpm), Annealed at 150°C for 30min, with a thickness of 40nm. Then prepare the quantum dot light-emitting layer, using 20mg / ml blue CdSe@ZnS quantum dot toluene solution, rotating at 2000rpm, annealing at 150°C for 30min, with a thickness of 20nm. The device was then transferred to a pressure of 10 -4 In the high vacuum chamber under Pa, 8nm BCPPA is vacuum-evaporated sequentially as the third hole transport layer; the 15nm doping material is MoO with a mass rat...

Embodiment 2

[0046] Substrate 1 was first ultrasonically treated with detergent, acetone, ethanol and isopropanol for 15 min each. Then a layer of ITO conductive film with a thickness of 150nm was sputtered on the substrate 1, and then UV-ozone was performed for 15 minutes. Next, the ZnO electron transport layer 3 was prepared in a glove box filled with nitrogen and extremely low in water and oxygen content by solution spin coating, using 20 mg / ml of ZnO nanoparticle ethanol solution at a speed of 1500 rpm (Resolutions per minute, rpm), Annealed at 150°C for 30min, with a thickness of 40nm. Then prepare the quantum dot light-emitting layer, using 20mg / ml blue CdSe@ZnS quantum dot toluene solution, rotating at 2000rpm, annealing at 150°C for 30min, with a thickness of 20nm. The device was then transferred to a pressure of 10 -4 In the high vacuum chamber under Pa, 8nm BCPPA is vacuum-evaporated sequentially as the third hole transport layer; the 20nm doping material is MoO with a mass rat...

Embodiment 3

[0048]Substrate 1 was first ultrasonically treated with detergent, acetone, ethanol and isopropanol for 15 min each. Then sputter a layer of ITO conductive film with a thickness of 200nm on the substrate, and then perform UV-ozone treatment for 15min. Next, the ZnO electron transport layer 3 was prepared in a glove box filled with nitrogen and extremely low in water and oxygen content by solution spin coating, using 20 mg / ml of ZnO nanoparticle ethanol solution at a speed of 1500 rpm (Resolutions per minute, rpm), Annealed at 150°C for 30min, with a thickness of 40nm. Then prepare the quantum dot light-emitting layer, using 20mg / ml blue CdSe@ZnS quantum dot toluene solution, rotating at 2000rpm, annealing at 150°C for 30min, with a thickness of 20nm. The device was then transferred to a pressure of 10 -4 In the high vacuum chamber under Pa, 10nm BCPPA is vacuum-evaporated sequentially as the third hole transport layer; the 20nm doping material is MoO with a mass ratio of 1:4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com