Preparation of polysaccharide-base hydrogel and application of polysaccharide-base hydrogel as adsorbent to waste water treatment

A hydrogel and polysaccharide technology, which is applied in the fields of adsorption water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of application limitation, small adsorption capacity, low selectivity, etc. The effect of abundant reserves, enhanced swelling performance and good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

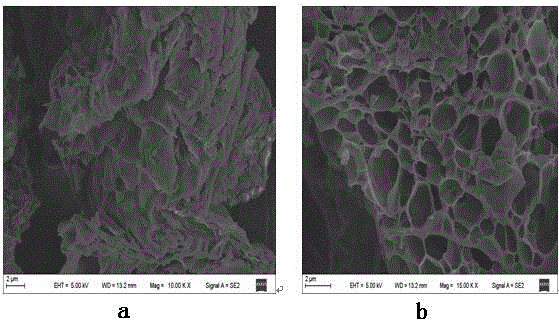

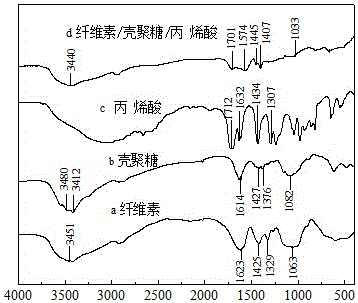

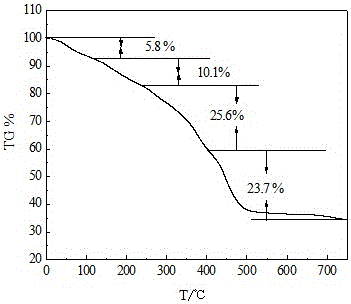

[0033] Dissolve 0.75g carboxymethylcellulose sodium (CMCNa) in 30mL deionized water; dissolve 0.25g chitosan (CTS) in 10mL0.1% acetic acid aqueous solution, after the dissolution is complete, slowly mix the two solutions and transfer them into 100mL three-port In the flask, stir magnetically at 30°C to make it evenly mixed; then add 10mL acrylic acid (AA), 3.2g polyethylene glycol (PEG), 0.1g N,N '-methylenebisacrylamide (MBA), 0.1 g ammonium persulfate (APS), N 2 After reacting at 60°C for 3 hours under protection, the temperature was raised to 90°C for 10 minutes to produce a gel; the product was cooled to room temperature, taken out and cut into pieces, neutralized with NaOH solution to make the neutralization degree reach 60%, and then deionized Wash with water, dehydrate with ethanol, dry in a vacuum oven at 40°C until constant weight, and grind to obtain CMC / CTS / AA / PEG hydrogel.

[0034] The swelling property of the hydrogel is 499g / g, and the adsorption capacity for me...

Embodiment 2

[0036] Dissolve 0.75g carboxymethylcellulose sodium (CMCNa) in 30mL deionized water, and 0.25g chitosan (CTS) in 10mL 0.1% acetic acid solution. After the dissolution is complete, slowly mix the two solutions and transfer them to a 100mL three-neck flask , stir magnetically at 30°C to make it evenly mixed. Then add 10 mL of acrylic acid (AA), 1.5 g of β-cyclodextrin (β-CD), 0.1 g N,N '-methylenebisacrylamide (MBA), 0.1 g ammonium persulfate (APS), N 2After reacting at 60°C for 3 hours under protection, the temperature was raised to 90°C for 10 minutes to produce gel. After the product was cooled to room temperature, it was taken out and cut into pieces, neutralized with NaOH solution to make the neutralization degree reach 60%, then washed with deionized water, dehydrated with ethanol, dried in a vacuum oven at 40°C to constant weight, and ground The CMC / CTS / AA / β-CD hydrogel was obtained.

[0037] The swelling property of the hydrogel is 640g / g, and the adsorption capacity ...

Embodiment 3

[0039] Dissolve 0.75g carboxymethylcellulose sodium (CMCNa) in 30mL deionized water, and 0.25g chitosan (CTS) in 10mL 0.1% acetic acid solution. After the dissolution is complete, slowly mix the two solutions and transfer them to a 100mL three-neck flask , stir magnetically at 30°C to mix evenly; then add 10mL acrylic acid (AA), 4g 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 0.1g N,N '-methylenebisacrylamide (MBA), 0.1 g ammonium persulfate (APS), N 2 After reacting at 60°C for 3 hours under protection, the temperature was raised to 90°C for 10 minutes to produce gel. After the product was cooled to room temperature, it was taken out and cut into pieces, neutralized with NaOH solution to make the neutralization degree reach 60%, then washed with deionized water, dehydrated with ethanol, dried in a vacuum oven at 40°C to constant weight, and ground The CMC / CTS / AA / AMPS hydrogel is obtained.

[0040] The swelling property of the hydrogel is 759g / g, and the adsorption capa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| swelling | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com