Catalyst for preparing MEK (Methyl Ethyl Ketone) by carrying out dehydrogenation on 2-butanol and preparation method and application thereof

A catalyst and a technology for sec-butanol, which are applied in the field of catalysts for preparing methyl ethyl ketone by dehydrogenation of sec-butanol and the field of preparation thereof, can solve the problems that it is difficult to meet the long-term operation of oxidation regeneration, affect the service life of the catalyst, increase the cost of catalyst preparation, etc. Selectivity, reducing catalyst carbon deposition, and improving the effect of methyl ethyl ketone selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] I. Catalyst preparation

[0024] Mix 45g of aluminum oxide, 5g of calcium oxide, 1g of magnesium oxide, and 1g of nickel oxide with a nitric acid solution with a mass concentration of 10% to form a ball, then extrude it, and dry it at a temperature of 40-70°C for 4 hours , and then calcined at 540° C. for 4 hours to obtain a catalyst carrier, and the carrier is made into particles with a length of 3-10 mm.

[0025] Weigh 41.10g of copper nitrate trihydrate and 3.84g of boric acid and dissolve them in absolute ethanol, heat and stir in a water bath until completely dissolved, and control the temperature of the water bath to 65±5°C. Immerse the equal volume of the prepared carrier particles in the ethanol solution for about 20 hours, dry at 40-70°C, and calcinate at 540°C for 4 hours to obtain catalyst A.

[0026] II. Catalyst Performance Evaluation

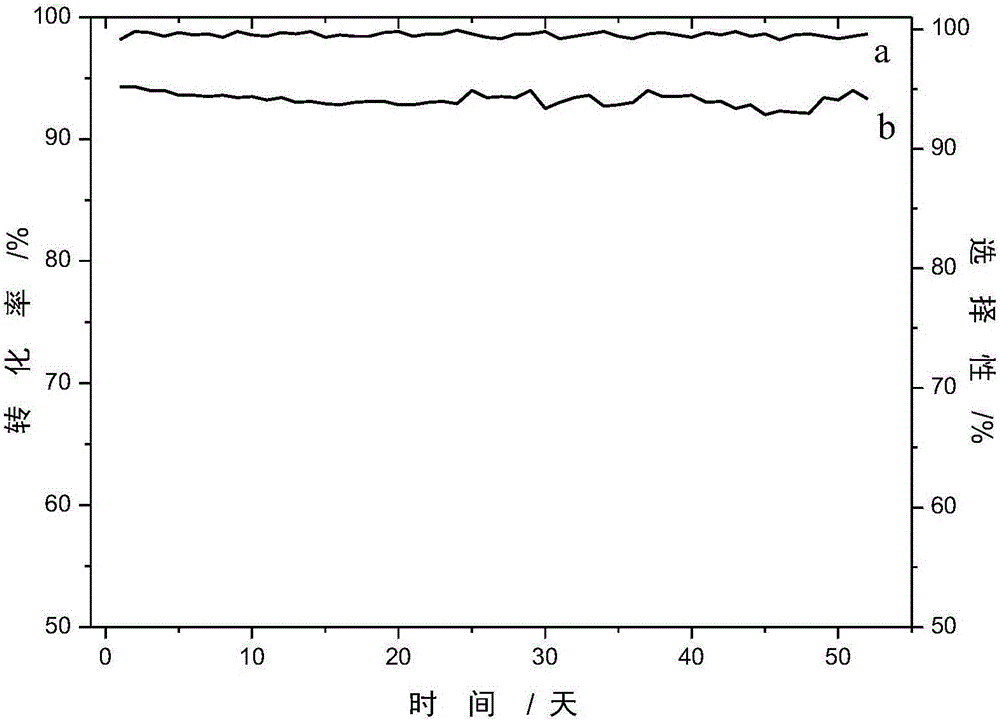

[0027] 10 g of catalyst A prepared above is used for the dehydrogenation of sec-butanol to produce methyl ethyl ketone, ...

Embodiment 2

[0030] I. Catalyst preparation

[0031] Mix 42.5g of aluminum oxide, 7.5g of calcium oxide, 1g of magnesium oxide, and 1g of nickel oxide with a nitric acid solution with a mass concentration of 10% to form a ball, then extrude it, and dry it at a temperature of 40-70°C 2 hours, and then calcined at 540° C. for 4 hours to obtain a catalyst carrier, and the carrier is made into particles with a length of 3-10 mm.

[0032] Weigh 41.10g of copper nitrate trihydrate and 3.84g of boric acid and dissolve them in absolute ethanol, heat and stir in a water bath until completely dissolved, and control the temperature of the water bath to 65±5°C. The carrier particles prepared above were immersed in the ethanol solution in an equal volume for about 20 hours, dried at 40-70°C, and calcined at 540°C for 4 hours to obtain catalyst B.

[0033] II. Catalyst Performance Evaluation

[0034] The dehydrogenation reaction process is the same as in Example 1, and the reaction results are: the co...

Embodiment 3

[0036] I. Catalyst preparation

[0037] Mix 35g of aluminum oxide, 15g of calcium oxide, 1g of magnesium oxide, and 1g of nickel oxide with a nitric acid solution with a mass concentration of 10% to form a ball, then extrude it, and dry it at a temperature of 40-70°C for 2 hours , and then calcined at 540° C. for 4 hours to obtain a catalyst carrier, and the carrier is made into particles with a length of 3-10 mm.

[0038] Weigh 41.10g of copper nitrate trihydrate and 3.84g of boric acid and dissolve them in absolute ethanol, heat and stir in a water bath until completely dissolved, and control the temperature of the water bath to 65±5°C. Immerse the equal volume of the prepared carrier particles in the ethanol solution for about 20 hours, dry at 40-70°C, and calcinate at 540°C for 4 hours to obtain catalyst C.

[0039] II. Catalyst Performance Evaluation

[0040] The dehydrogenation reaction process is the same as in Example 1, and the reaction results are: the conversion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com