A method for preparing nano-silicon based on halloysite raw material

A technology of nano-silicon and nano-silicon dioxide, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the unfavorable large-scale production of nano-silicon materials, the inability to obtain nano-silicon materials, high Toxicity and other issues can be achieved to improve the nano-silicon morphology, uniform pore size distribution, and reduce the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Take 5g of halloysite and add it to 500mL of sulfuric acid solution with a concentration of 2mol / L, react at 100°C for 10h, filter and wash with water until neutral, and dry in an oven at 80°C to obtain the desired silica intermediate product .

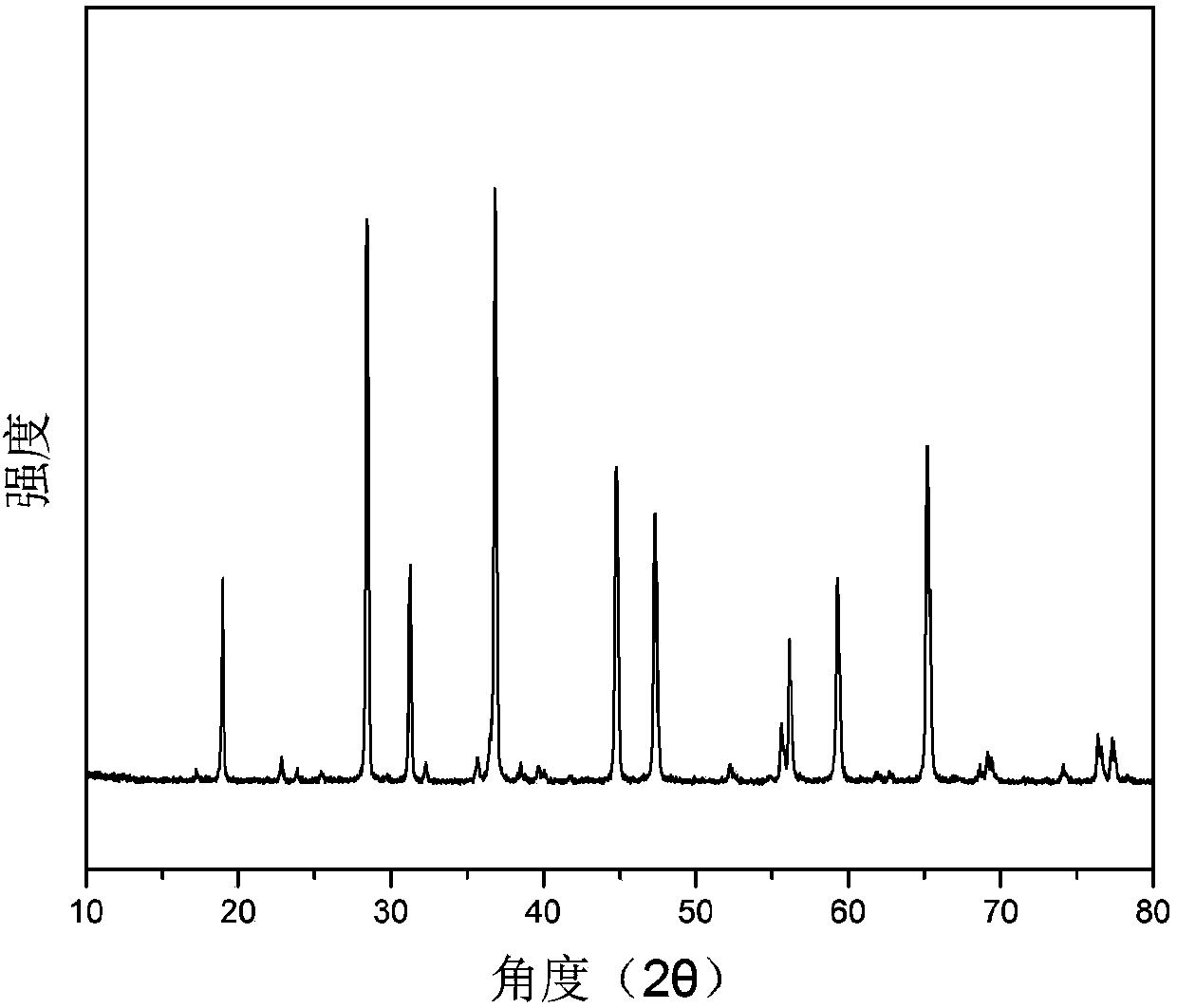

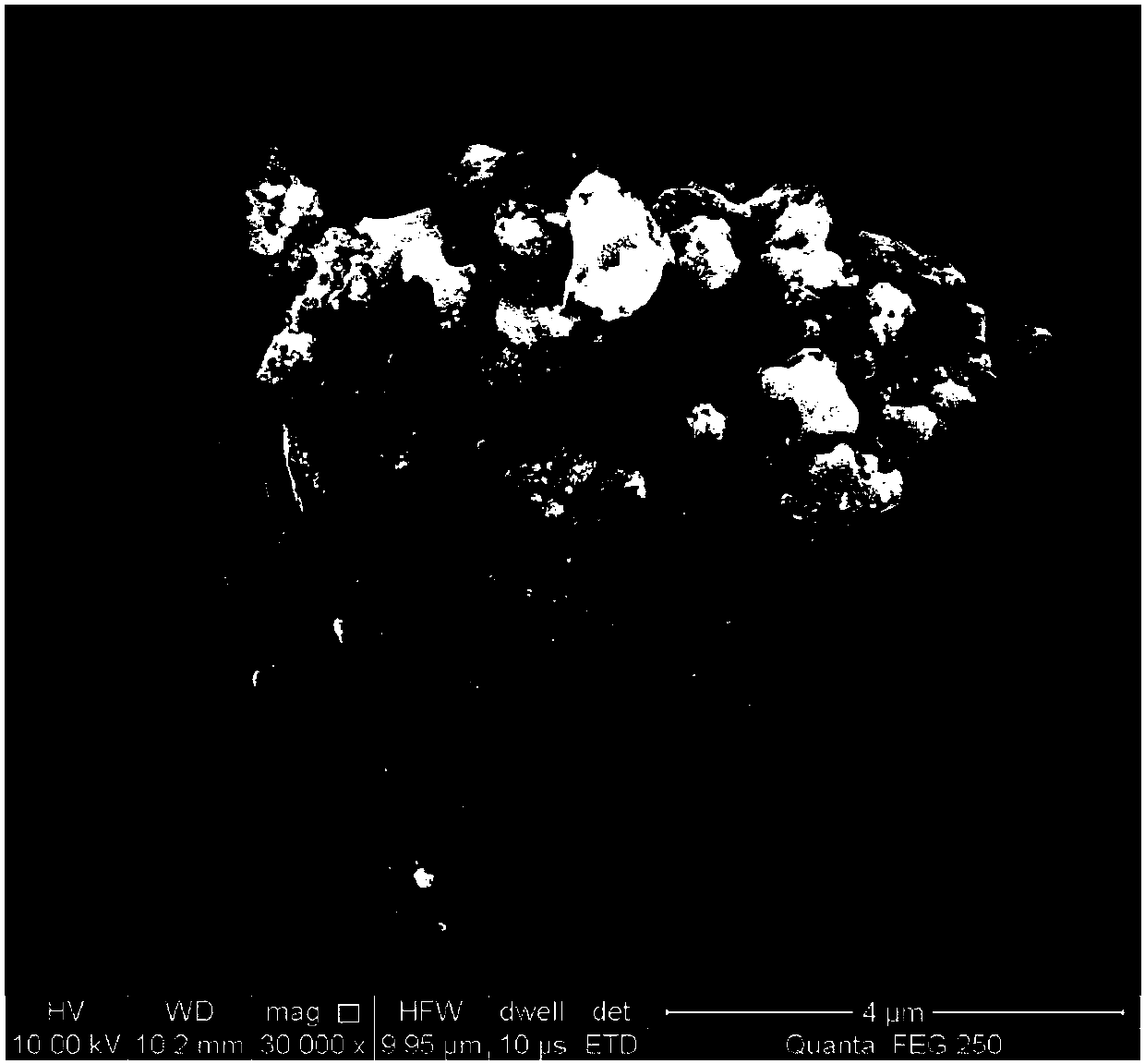

[0052] (2) Take the above 1g of silicon dioxide, mix it with 10g of sodium chloride, add 0.9g of metal magnesium powder, place it in a sealed tube furnace, raise the temperature to 700°C at 5°C / min and keep it for 10h under an argon atmosphere. After cooling, the product was treated in 1mol / L hydrochloric acid for 6h, filtered and then treated in 5wt% hydrofluoric acid for 0.5h, filtered and washed to neutrality, and dried at 80°C to obtain a nano-silicon material. The X-ray diffraction pattern is as follows Figure 4 As shown, the scanning electron microscope as Figure 5 As shown, the transmission electron microscope is shown as Figure 6 As shown, the pore size distribution is as Figure 7 As shown, the nitrogen adsor...

Embodiment 2

[0055] (1) Take 5g of halloysite and add it to 500mL of hydrochloric acid solution with a concentration of 1mol / L, react at 90°C for 12h, filter and wash with water until neutral, and dry in an oven at 80°C to obtain the desired silica intermediate product .

[0056] (2) Take the above 1g of silicon dioxide, mix it with 5g of sodium chloride and 5g of potassium chloride, then add 0.8g of metal magnesium powder, place it in a sealed tube furnace, and raise the temperature at 2°C / min to Insulate at 650°C for 10h, after cooling, the product is treated in 2mol / L hydrochloric acid for 6h, filtered and then treated in 10wt% hydrofluoric acid for 0.5h, filtered and washed with water until neutral, dried at 80°C to obtain the morphology of Example 1 The same nano-silicon material.

[0057] The prepared material was made into a negative electrode sheet of a lithium ion battery according to the method in Example 1, and a simulated battery was assembled. Under the current density of 20...

Embodiment 3

[0059] (1) Add 5g of halloysite to 300mL of sulfuric acid solution with a concentration of 3mol / L, react at 120°C for 5h, filter and wash with water until neutral, and dry in an oven at 80°C to obtain the desired silica intermediate product .

[0060] (2) Take the above 1g of silicon dioxide, mix it with 20g of potassium chloride, add 1g of metal magnesium powder, put it in a sealed tube furnace, heat it up to 1000°C at 10°C / min under an argon atmosphere and keep it warm for 6h, then cool The final product was treated in 1mol / L sulfuric acid for 12h, filtered and then treated in 5wt% hydrofluoric acid for 1h, filtered and washed with water until neutral, and dried at 80°C to obtain a nano-silicon material with the same appearance as Example 1.

[0061] The prepared material was made into a negative electrode sheet of a lithium ion battery according to the method in Example 1, and a simulated battery was assembled. Under the current density of 200mA / g, the prepared battery com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com