A method for extracting pectin from waste sisal residue

A technology of sisal residue and pectin, which is applied in the field of plant component extraction, can solve the problems affecting later application and low molecular weight of pectin, and achieve the effects of low consumption, light color and low degree of esterification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

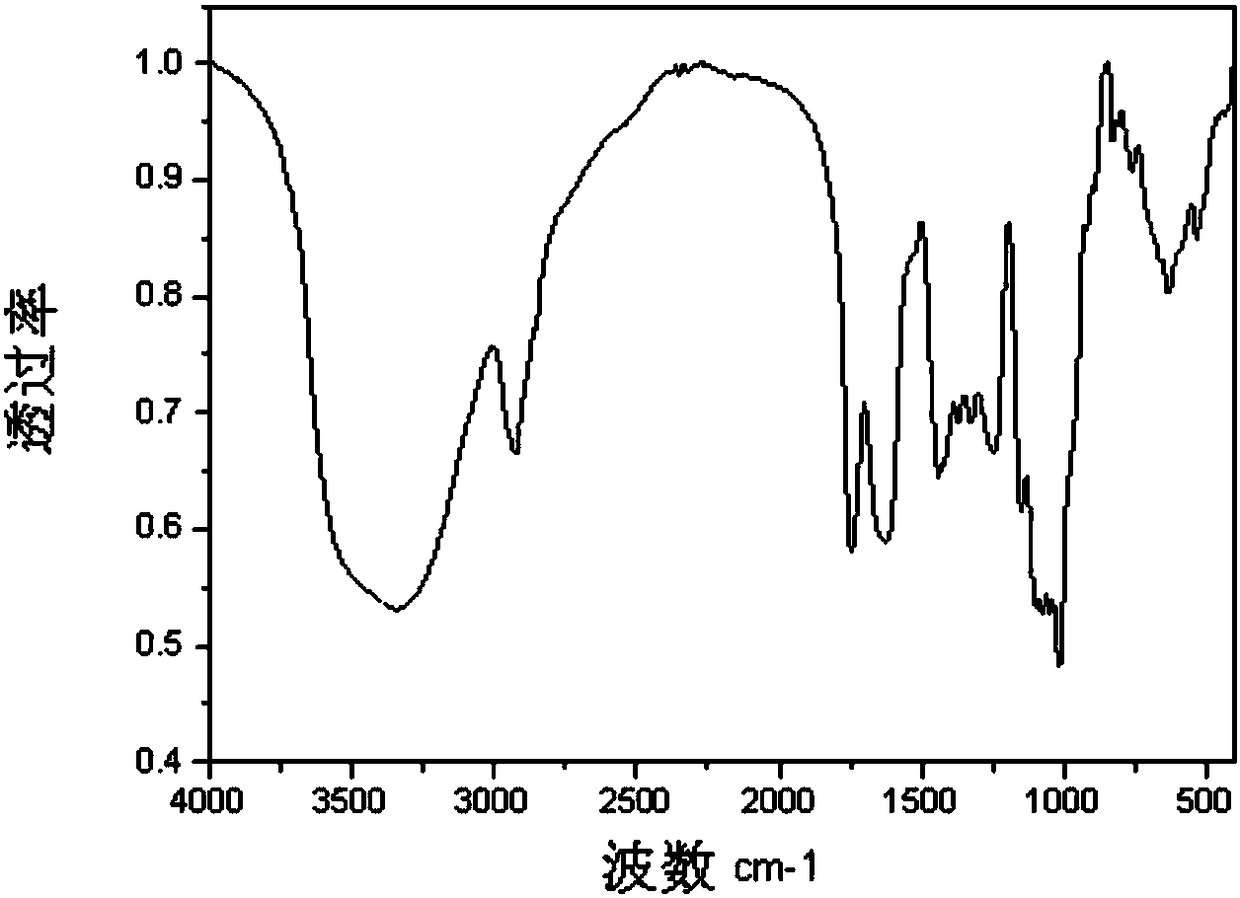

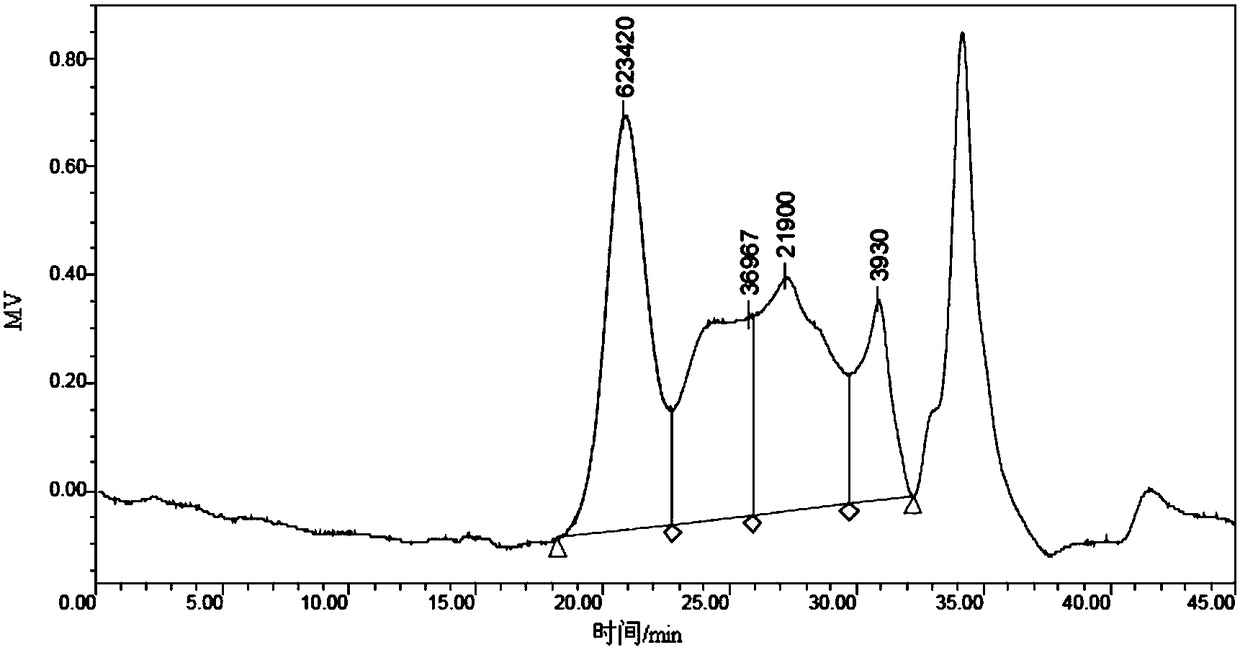

Embodiment 1

[0034] The sisal slag after fiber extraction was washed with clean water for several times, to remove impurities, and air-dried at 60°C for 10 hours. The dried sisal slag was mechanically pulverized with a Bailey micro-powder machine for 30 minutes, and the sisal slag fine powder was passed through the pores in turn. 2.0mm and 0.5mm sieves, sealed in a sample bag, and stored in a dry place at room temperature; mix the sisal residues in hot water at 85°C, stir well, let stand for 20min, rinse twice with clean water, and drum at 60°C Air-dry for 6 hours; take 100 g of dried sisal residue powder, put it in a Soxhlet extractor, use toluene-ethanol (2:1, V / V) as solvent, extract at 50°C for 4 hours to degrease, and then take out the sisal residue , air-dried at 60°C for 16 h; add 500 mL of 0.1 mol / L HAc-NaAc buffer solution (pH4. 0), after stirring evenly, add 40 μl of cellulose complex enzyme Celluclast 1.5L, shake and extract in a shaker water bath at 45°C for 18h, then heat the ...

Embodiment 2

[0037]The sisal slag after fiber extraction was washed with clean water for several times, to remove impurities, and air-dried at 60°C for 10 hours. The dried sisal slag was mechanically pulverized with a Bailey micro-powder machine for 30 minutes, and the sisal slag fine powder was passed through the pores in turn. 2.0mm and 0.5mm sieves, sealed in a sample bag, and stored in a dry place at room temperature; mix the sisal residues in hot water at 85°C, stir well, let stand for 20min, rinse twice with clean water, and drum at 60°C Air-dry for 6 hours; take 100 g of dried sisal residue powder, put it in a Soxhlet extractor, use toluene-ethanol (2:1, V / V) as solvent, extract at 50°C for 4 hours to degrease, and then take out the sisal residue , air-drying at 60°C for 16 hours; add 800mL of 0.1mol / L HAc-NaAc buffer solution (pH4. 0), after stirring evenly, add 85 μl of cellulose complex enzyme Celluclast 1.5L, shake and extract in a shaker water bath at 45°C for 18h, then heat th...

Embodiment 3

[0039] The sisal slag after fiber extraction was washed with clean water for several times, to remove impurities, and air-dried at 60°C for 10 hours. The dried sisal slag was mechanically pulverized with a Bailey micro-powder machine for 30 minutes, and the sisal slag fine powder was passed through the pores in turn. 2.0mm and 0.5mm sieves, sealed in a sample bag, and stored in a dry place at room temperature; mix the sisal residues in hot water at 85°C, stir well, let stand for 20min, rinse twice with clean water, and drum at 60°C Air-dry for 6 hours; take 100 g of dried sisal residue powder, put it in a Soxhlet extractor, use toluene-ethanol (2:1, V / V) as solvent, extract at 50°C for 4 hours to degrease, and then take out the sisal residue , air-dried at 60°C for 16 h; add 500 mL of 0.1 mol / L HAc-NaAc buffer solution (pH4. 0), after stirring evenly, add 40 μl of cellulose complex enzyme Celluclast 1.5L, shake and extract in a shaker water bath at 45°C for 18h, then heat the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com