Special-type high-strength wear-resistant water-based epoxy paint and preparation method thereof

A technology of water-based epoxy resin and epoxy paint, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems of poor wear resistance, insufficient strength and impact resistance of water-based epoxy paint, and achieve moderate hardness, The effect of long application period and good complementary coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

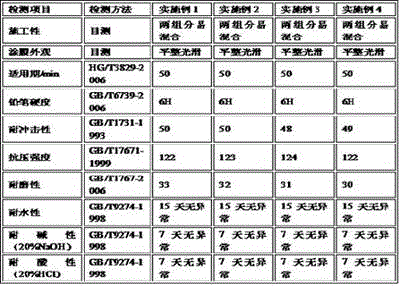

Examples

Embodiment 1

[0043] Step 1: Put 87.0g of water-based epoxy resin and 10.0g of reactive diluent into the reaction kettle;

[0044] Step 2: Under stirring conditions, slowly raise the temperature to 60°C, keep it at (60±2)°C for 1 hour, and then cool down to 40°C;

[0045] Step 3: After filtering with a 180-mesh silk screen, the first component of the water-based epoxy paint is obtained;

[0046] Step 4: Add 21.3g of deionized water, 33.0g of water-based amine curing agent I, and 11.0g of water-based amine curing agent II into the container, and stir evenly;

[0047] Step 5: Add 10g of tungsten carbide, 5g of spodumene, 15.0g of titanium dioxide, 0.2g of carbon black, 8.0g of silicon micropowder, and 8.0g of precipitated barium sulfate into the container under stirring conditions, stir for 30 minutes after adding, and then Use a sand mill to disperse to a fineness of ≤25 μm to prepare a slurry;

[0048] Step 6: Add 3.0 g of functional resin, 0.3 g of defoamer, and 0.2 g of wetting and leve...

Embodiment 2

[0051] Step 1: Put 80.0g of water-based epoxy resin and 15.0g of water-soluble reactive diluent into the reaction kettle;

[0052] Step 2: Under stirring conditions, slowly raise the temperature to 60°C, keep it at (60±2)°C for 1 hour, and then cool down to 40°C;

[0053] Step 3: After filtering with a 180-mesh silk screen, the first component of the water-based epoxy paint is obtained;

[0054] Step 4: Add 25.0g of deionized water, 33.0g of water-based amine curing agent I, and 11.0g of water-based amine curing agent II into the container, and stir evenly;

[0055] Step 5: Add 8g of tungsten carbide, 5g of spodumene, 1.0g of titanium dioxide, 3.0g of iron oxide yellow, 1.5g of phthalocyanine green, 12.0g of silicon micropowder, and 12.0g of precipitated barium sulfate into the container under stirring conditions. Stir for 30 minutes after completion, and then use a sand mill to disperse to a fineness of ≤25 μm to prepare a slurry;

[0056] Step 6: Add functional resin 3.0, ...

Embodiment 3

[0059] Step 1: Put 90.0g of water-based epoxy resin and 10.0g of water-soluble diluent into the reaction kettle;

[0060] Step 2: Under stirring conditions, slowly raise the temperature to 60°C, keep it at (60±2)°C for 1 hour, and then cool down to 40°C;

[0061] Step 3: After filtering with a 180-mesh silk screen, the first component of the water-based epoxy paint is obtained;

[0062] Step 4: Add 20.0 deionized water, 30.0 water-based amine curing agent I, and 10.0 water-based amine curing agent II into the container, and stir evenly;

[0063]Step 5: Under stirring conditions, add 10g of tungsten carbide, 4g of spodumene, 1.0g of titanium dioxide, 1.0g of iron oxide yellow, 1.0g of phthalocyanine green, 5.0g of silicon micropowder, and 5.0g of precipitated barium sulfate into the container, and add Stir for 30 minutes after completion, and then use a sand mill to disperse to a fineness of ≤25 μm to prepare a slurry;

[0064] Step 6: Add 5.0 g of functional resin, 0.1 g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com