Composition or compound bacterial agent for treating waste drilling mud

A technology of compound bacterial agent and drilling mud, which is applied in the direction of biological sludge treatment, microbial-based methods, bacteria, etc., and can solve problems such as refractory treatment, large biological toxicity, and harm to the soil ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

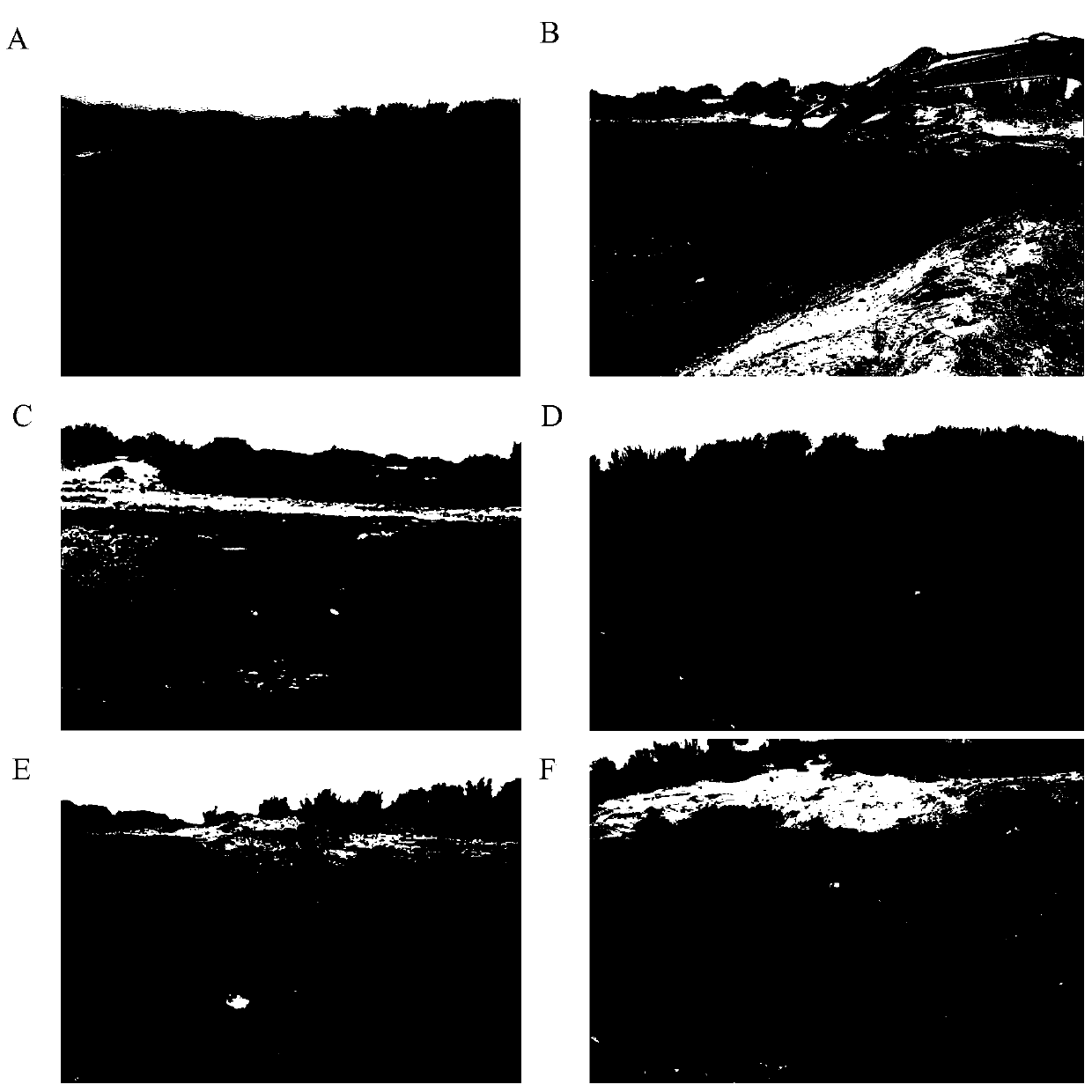

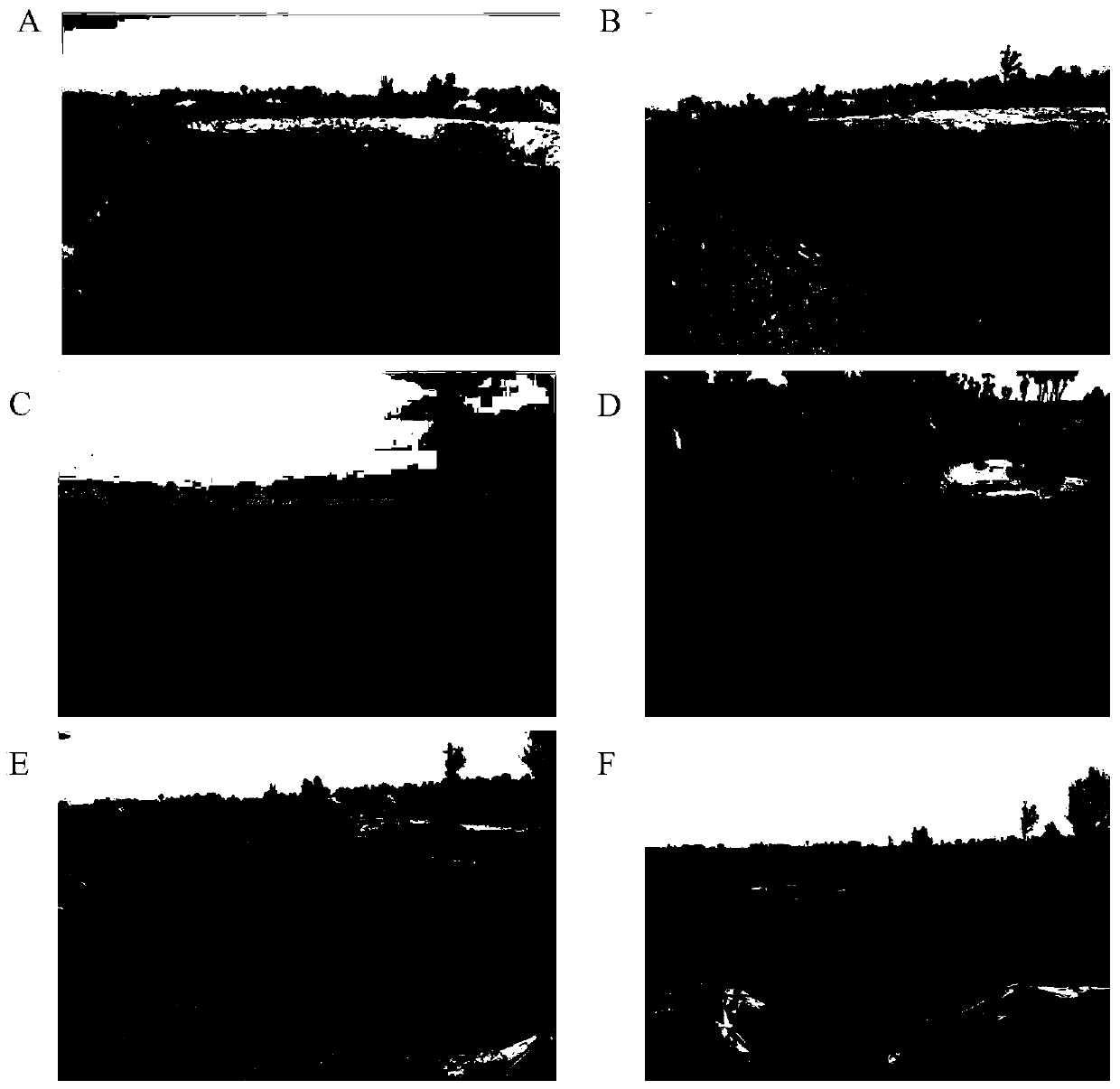

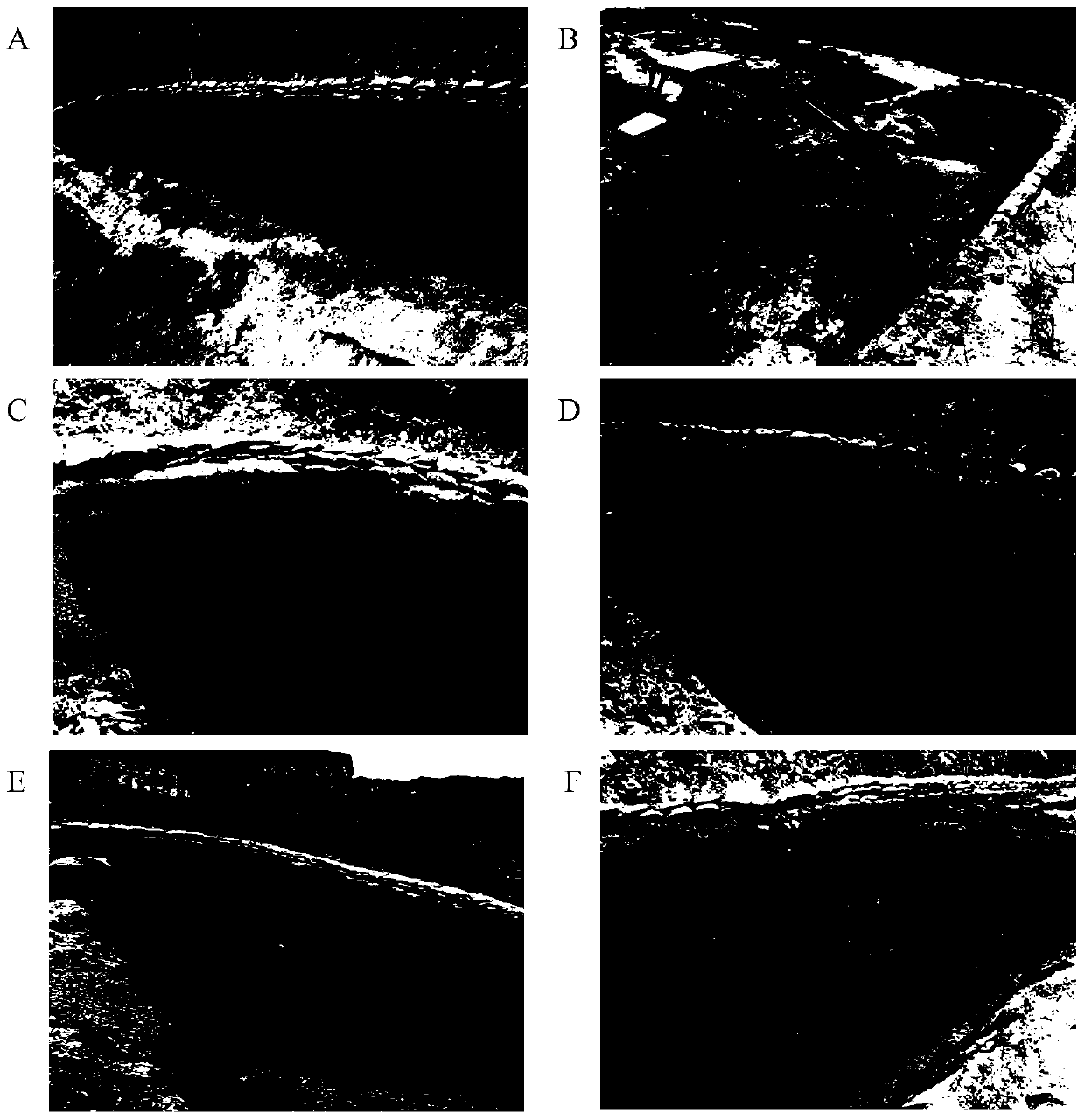

Image

Examples

preparation example Construction

[0059] On the other hand, the present application also relates to a preparation method of a composite bacterial agent, comprising:

[0060] Bacillus subtilis (Bacillus subtilis), Pseudomonas stutzeri (Pseudomonas stutzeri) and John's Acinetobacter (Acinetobacter johnsonii) are cultured separately; The above combinations are mixed to obtain the composite microbial agent.

[0061] Optionally, the above culture is solid culture, semi-solid culture or liquid culture.

[0062] In some embodiments, in the preparation method of the compound microbial agent, the weight of the respective cultures of the bacterial strains is used for mixing. When mixing, the Bacillus subtilis culture, the Pseudomonas stutzeri culture and about The parts by weight of Acinetobacter subtilis culture are:

[0063] Bacillus subtilis culture 1~3

[0064] Pseudomonas stutzeri cultures 1-6

[0065] Acinetobacter johnsonii culture 1-6;

[0066] Optionally, the strain culture comprises a strain and a culture...

Embodiment 1

[0140] Example 1 Treatment of waste oil-based mud from shale gas wells

[0141] Harmless treatment of about 1,000 cubic meters of waste oil-based mud produced by a shale gas well.

[0142] The shale gas well site is located on the edge of the Mu Us Desert, surrounded by sand dunes and a few farmlands. It has been drilled and handed over for nearly a year. The waste liquid from the upper layer of the mud pool has basically evaporated naturally. There is no obvious seepage in the pool. In the air-dried layer of 2-3 cm, the water content of the mixed waste under the air-dried layer is 80-90%, the pH value is 13, and the physical state is viscose. Before the treatment, the ambient temperature was 30°C, and the temperature in the mud pool was 17°C. Add the compound bacterial agent into the waste mud pool and stir it before treatment. During the treatment, the ambient temperature was 12-30°C, and the treatment monitoring time was 30 days. During this period, there were two rain pro...

Embodiment 2

[0166] Example 2 Treatment of oil well waste oil-based mud

[0167] Harmless treatment of about 800 cubic meters of waste oil-based mud produced by an oil well.

[0168] The oil well site is located on the edge of the village, and the surrounding landforms are all plowed farmland. The drilling has just been completed, and the pH value of the bottom mud is 13-14, and the physical state is viscose. 18°C, and the bottom mud is 8-10°C. After stirring, the water content of the waste mud is more than 90%, the pH value is 11-12, the temperature is 15-16°C, and the physical state is dilute colloid. The composite bacterial agent is added into the waste mud pool and then stirred for treatment. During the treatment, the ambient temperature is 16-28°C, and the treatment monitoring time is 35 days.

[0169] 1) Shake flask culture: Inoculate Bacillus subtilis, Pseudomonas stutzeri and Acinetobacter johnsoni into beef extract peptone liquid medium for shake flask culture, all cultured at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com