A preparing method of a sodium ion battery cathode material Na3V2(PO4)3/C

A technology for sodium ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor ion conductivity, high cost, and complicated steps, achieve uniform particles, avoid material agglomeration, and save steps when the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 2.5mmol V 2 o 5 , 3.75 mmol Na 2 CO 3 , 7.5mmol NH 4 h 2 PO 4 , 3.75mmol citric acid and 0.8mmol PVP were dissolved in 120ml deionized water, and stirred evenly; the above solution was heated and stirred at 80°C for 8h, evaporated to form a sol, transferred to a petri dish, freeze-dried at -55°C for 7h, and ground get the precursor.

[0032] Place the above precursors in a mixed gas of hydrogen and argon (5% H 2 (v / v)) in a tube furnace, pre-calcined at 350 °C for 4 h, calcined at 800 °C for 12 h, and naturally cooled to obtain Na 3 V 2 (PO 4 ) 3 / C material.

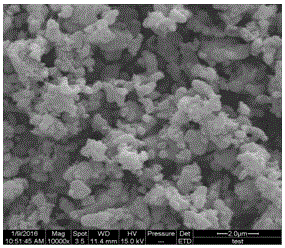

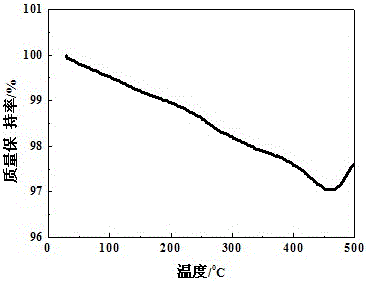

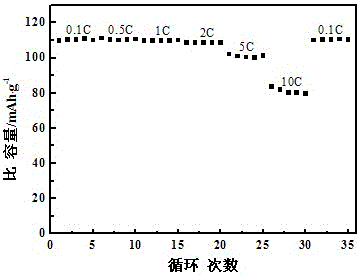

[0033] Depend on Figure 1~5 It can be seen that: Na 3 V 2 (PO 4 ) 3 The / C material has uniform particles, the particle size is between 1 and 2 μm, and the carbon content of the material is 3%. The material is used as a positive electrode material, acetylene black is used as a conductive agent, and PVDF is used as a binder to prepare a pole piece, wherein the mass ratio of active material:...

Embodiment 2

[0035] Weigh 2.5mmol V 2 o 5 , 7.5mmol NaOH, 7.5mmol NH 4 h 2 PO 4 , 2mmol ascorbic acid, 1mmol oxalic acid and 0.5mmol PEG were dissolved in 120ml deionized water, and stirred evenly; the above solution was heated and stirred at 70°C for 14h, evaporated to form a sol, transferred to a petri dish, and freeze-dried at -45°C for 12h. Grinding to obtain the precursor.

[0036] The above precursors were placed in an argon atmosphere tube furnace, pre-calcined at 400 °C for 3 h, calcined at 700 °C for 16 h, and naturally cooled to obtain Na 3 V 2 (PO 4 ) 3 / C material.

[0037] Na prepared in this example 3 V 2 (PO 4 ) 3 The particle size of the / C material is between 2 and 5 μm, and the carbon content of the material is 2.3%. The material is used as a positive electrode material, acetylene black is used as a conductive agent, and PVDF is used as a binder to prepare a pole piece, wherein the mass ratio of active material: conductive agent: binder is 70:20:10. A battery ...

Embodiment 3

[0039] Weigh 5mmol NH 4 VO 3 , 7.5mmol NaH 2 PO 4 , 5mmol sucrose and 1mmol CTAB were dissolved in 120ml deionized water, and stirred evenly; the above solution was heated and stirred at 75°C for 12h, evaporated to form a sol, transferred to a petri dish, freeze-dried at -50°C for 10h, and ground to obtain the precursor .

[0040] The above precursors were placed in a nitrogen atmosphere tube furnace, pre-calcined at 400 °C for 4 h, calcined at 850 °C for 8 h, and naturally cooled to obtain Na 3 V 2 (PO 4 ) 3 / C material.

[0041] Na prepared in this example 3 V 2 (PO 4 ) 3 The / C material has uniform particles, the particle size is between 1 and 3 μm, and the carbon content of the material is 4.6%. The material is used as a positive electrode material, acetylene black is used as a conductive agent, and PVDF is used as a binder to prepare a pole piece, wherein the mass ratio of active material: conductive agent: binder is 70:20:10. The battery is assembled with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com