Agaricus bisporus and hippophae rhamnoides instant tea and preparation method thereof

A bisporus mushroom sand and instant tea technology, which is applied in the direction of tea substitutes, etc., can solve the problems of unacceptable to consumers, heavy old taste, green flavor, etc., and achieve the effect of improving bad flavor, delicious taste, and sufficient color and fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

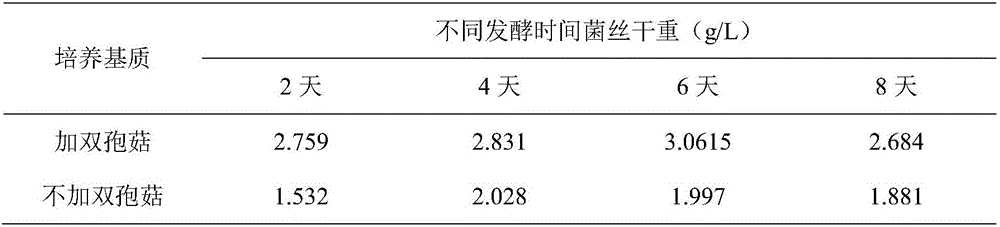

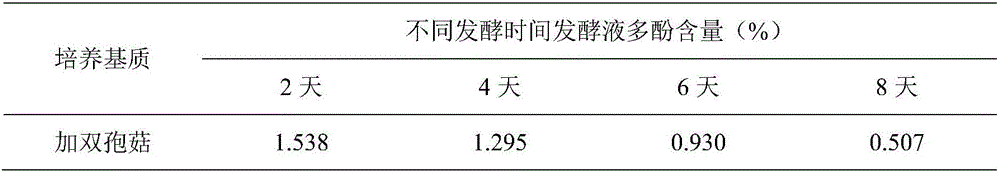

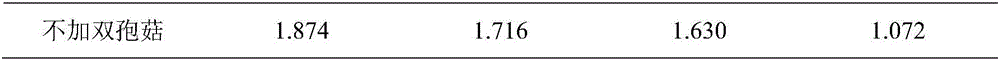

Examples

Embodiment 1

[0035] A bisporus seabuckthorn instant tea, the preparation raw materials mainly include seabuckthorn leaves and bisporus, and the specific processing steps are as follows:

[0036] Seabuckthorn leaf pretreatment: Take 200 kg of sun-dried seabuckthorn leaves, put them into an extraction tank after being pulverized by a pulverizer, add 2600 kg of demineralized water at 75°C, that is: the ratio of material to liquid is 1:13, soak at 95°C Extract for 50 minutes;

[0037] Filter seabuckthorn leaves: first pass the soaked solution through a 40-mesh filter to remove residues, and then pass through a 100-mesh filter to remove the residues to obtain seabuckthorn leaf water extract.

[0038] Agaricus bisporus pulping: take the dried Agaricus bisporus to remove the rotten part, accurately weigh 10 kg of the processed dried Agaricus bisporus, wash it, and add 200 kg of demineralized water at 90°C after beating with a beater, that is, the ratio of material to liquid is 1:20. Soak and ext...

Embodiment 2

[0071] A bisporus seabuckthorn instant tea, the preparation raw materials mainly include seabuckthorn leaves and bisporus mushroom, and the specific processing steps are as follows:

[0072] Seabuckthorn leaf pretreatment: Take 200 kg of sun-dried seabuckthorn leaves, crush them with a pulverizer, put them into an extraction tank, add 2000 kg of demineralized water at 95°C, that is, the ratio of material to liquid is 1:10, and soak at 95°C Extract for 40 minutes;

[0073] Filter seabuckthorn leaves: first pass the soaked solution through a 40-mesh filter to remove residues, and then pass through a 100-mesh filter to remove the residues to obtain seabuckthorn leaf water extract.

[0074] Agaricus bisporus pulping: Take the dried Agaricus bisporus to remove the rotten part, accurately weigh 10 kg of the processed dried Agaricus bisporus, wash it, and add 100 kg of demineralized water at 80°C after beating with a beater, that is, the ratio of material to liquid is 1:10. Soak and...

Embodiment 3

[0086] A bisporus seabuckthorn instant tea, the preparation raw materials mainly include seabuckthorn leaves and bisporus mushroom, and the specific processing steps are as follows:

[0087] Seabuckthorn leaf pretreatment: Take 150 kg of sun-dried seabuckthorn leaves, crush them with a pulverizer, put them into an extraction tank, add 3,750 kg of demineralized water at 95°C, that is, the ratio of material to liquid is 1:25, and soak at 95°C Extract for 40 minutes;

[0088] Filter seabuckthorn leaves: first pass the soaked solution through a 40-mesh filter to remove residues, and then pass through a 100-mesh filter to remove the residues to obtain seabuckthorn leaf water extract.

[0089] Agaricus bisporus pulping: Take the dried Agaricus bisporus to remove the rotten part, accurately weigh 10 kg of the processed dried Agaricus bisporus, wash it, and add 100 kg of demineralized water at 85°C after beating with a beater, that is, the ratio of material to liquid is 1:10. Soak an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com