Regenerated liquid capable of effectively recovering activity of sintered vanadium-based SCR catalyst

A technology of SCR catalyst and regeneration liquid, which is applied in the field of regeneration liquid for effectively restoring the activity of sintered vanadium-based SCR catalyst, can solve the problems of acceleration performance, increased regeneration cost, reduced catalytic activity, etc. Cost, effect of restoring catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

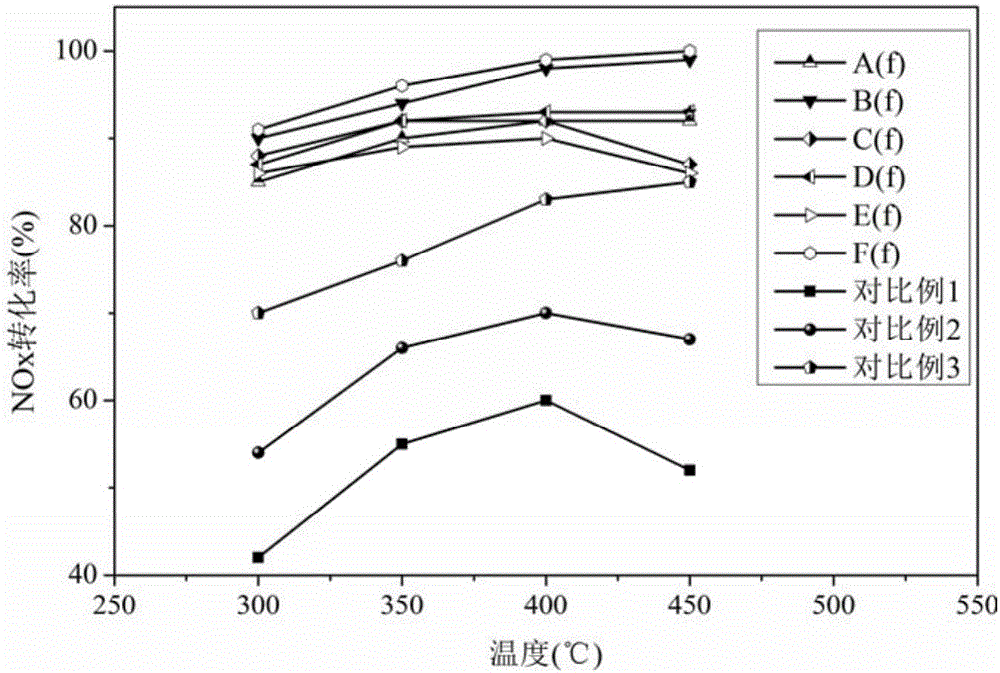

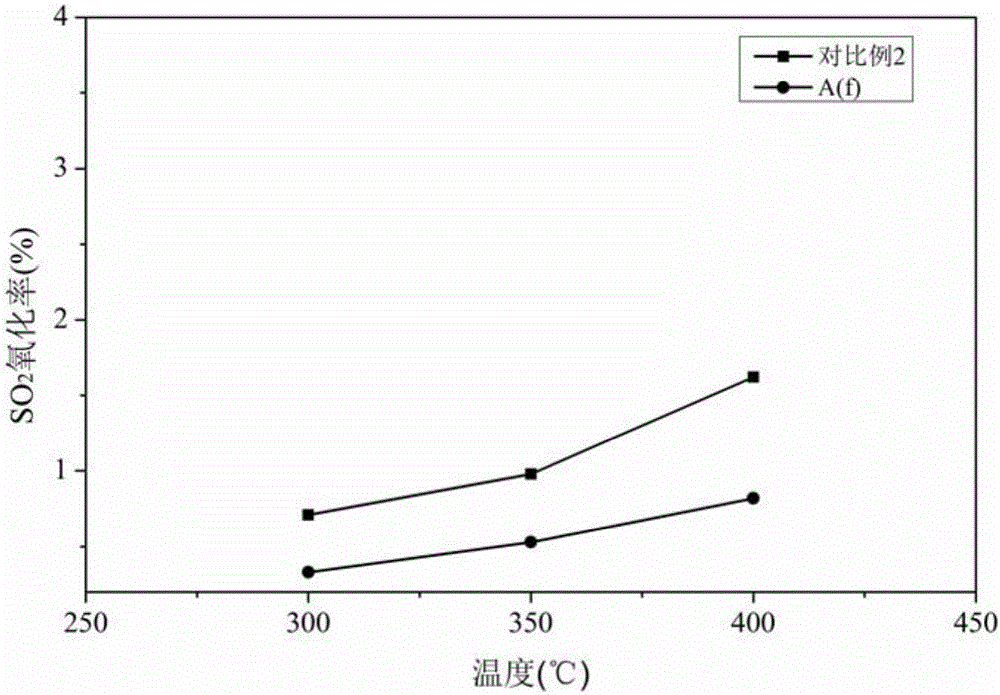

Embodiment 1

[0023] Dissolve 3 parts of ammonium thiosulfate, 1.5 parts of ammonium fluoride, and 0.6 parts of ammonium adipate in 100 parts of deionized water, and then add 1.7 parts of ammonium metavanadate (NH 4 VO 3 ), 3 parts of ammonium metatungstate, 10 parts of metatitanic acid and 5 parts of silica sol were stirred and dissolved to obtain the regeneration solution.

[0024] The vanadium-based SCR catalyst deactivated by sintering is blown with compressed air to remove dust, pickled with sulfuric acid, then immersed in the prepared regeneration solution for half an hour, dried at 70°C for 2 hours, and dried at 150°C for 2 hours to obtain fresh The regenerated catalyst A(f).

Embodiment 2

[0026] Dissolve 2 parts of ammonium thiosulfate, 1 part of ammonium fluoride, and 0.1 part of ammonium adipate in 100 parts of deionized water, then add 3 parts of vanadyl oxalate, 5 parts of tungsten trioxide, 40 parts of metatitanic acid and 3 Parts of silica sol were stirred and dissolved to obtain regeneration solution.

[0027] The sintered deactivated vanadium-based SCR catalyst was removed according to the method described in Example 1, then immersed in the regeneration solution prepared in this example for half an hour, dried at 70°C for 2 hours, and dried at 150°C for 2 hours to obtain fresh Catalyst B(f) is regenerated.

Embodiment 3

[0029] Dissolve 4 parts of ammonium thiosulfate, 2 parts of ammonium fluoride, and 1 part of triethylene glycol in 100 parts of deionized water, then add 2 parts of ammonium metavanadate, 3 parts of ammonium metatungstate, and 15 parts of titanium Silica powder and 15 parts of silica sol were stirred and dissolved to obtain regeneration solution.

[0030] The sintered deactivated vanadium-based SCR catalyst was removed according to the method described in Example 1, then immersed in the regeneration solution prepared in this example for half an hour, dried at 70°C for 2 hours, and dried at 150°C for 2 hours to obtain fresh Catalyst C(f) is regenerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com