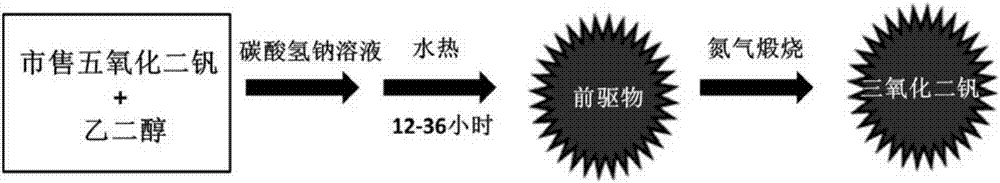

A kind of vanadium trioxide micro-nano particles and preparation method thereof

A vanadium trioxide micro-nano and micro-nano particle technology, applied in the nanometer field, can solve the problems of complex methods, waste acid production in products, and high cost of raw materials, and achieve the effects of wide application prospects, mild method conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

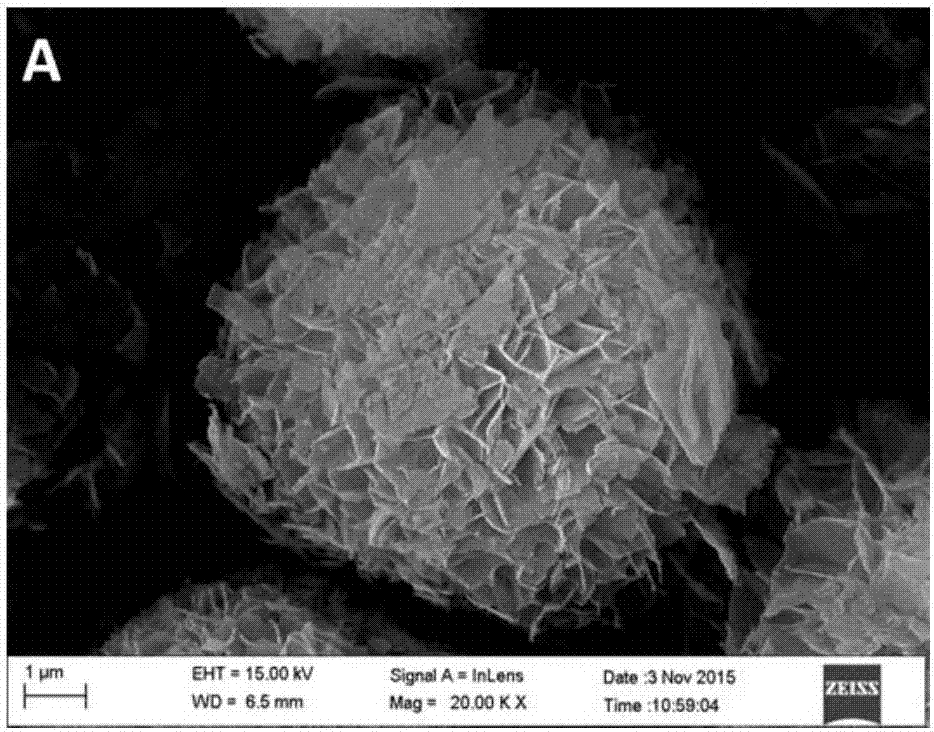

[0049] Follow the steps below to prepare micro-nanoparticles:

[0050] 1) Synthesis of flower-like vanadium oxide precursors formed by self-assembly of nanosheets:

[0051] 1.1) Add commercial vanadium pentoxide into the ethylene glycol solution, and vigorously stir in a water bath at 50° C. for 2 hours to make it evenly mixed to form a suspension A; the molar concentration of the suspension A is 0.075 mM;

[0052] 1.2) Add 1 mL of sodium bicarbonate solution to the suspension A to change the color of the suspension from brownish yellow to light yellow to form suspension B, wherein the molar concentration of the sodium bicarbonate solution is 1.5M;

[0053]1.3) Put the suspension B in an autoclave and heat it at 180°C for 12 hours. After standing at room temperature and cooling, the precursor containing black precipitate can be obtained;

[0054] 1.4) Centrifuge the product mixture solution containing precipitate formed in step 1.3) at a centrifugal speed of 2000-3000 rpm, wa...

Embodiment 2

[0058] Follow the steps below to prepare micro-nanoparticles:

[0059] 1) Synthesis of flower-like vanadium oxide precursors formed by self-assembly of nanosheets:

[0060] 1.1) Add commercial vanadium pentoxide into ethylene glycol solution, and vigorously stir in a water bath at 70° C. for 2 hours to make it evenly mixed to form a suspension A; the molar concentration of the suspension A is 0.3 mM;

[0061] 1.2) Add 10 mL of sodium bicarbonate solution to the suspension A to change the color of the suspension from brownish yellow to light yellow to form suspension B, wherein the molar concentration of the sodium bicarbonate solution is 1M;

[0062] 1.3) Put the suspension B into an autoclave and heat it at 260°C for 36 hours. After standing at room temperature and cooling, the precursor containing black precipitate can be obtained;

[0063] 1.4) Centrifuge the product mixed solution containing precipitate formed in step 1.3) at a centrifugal speed of 2000-3000 rpm, wash wit...

Embodiment 3

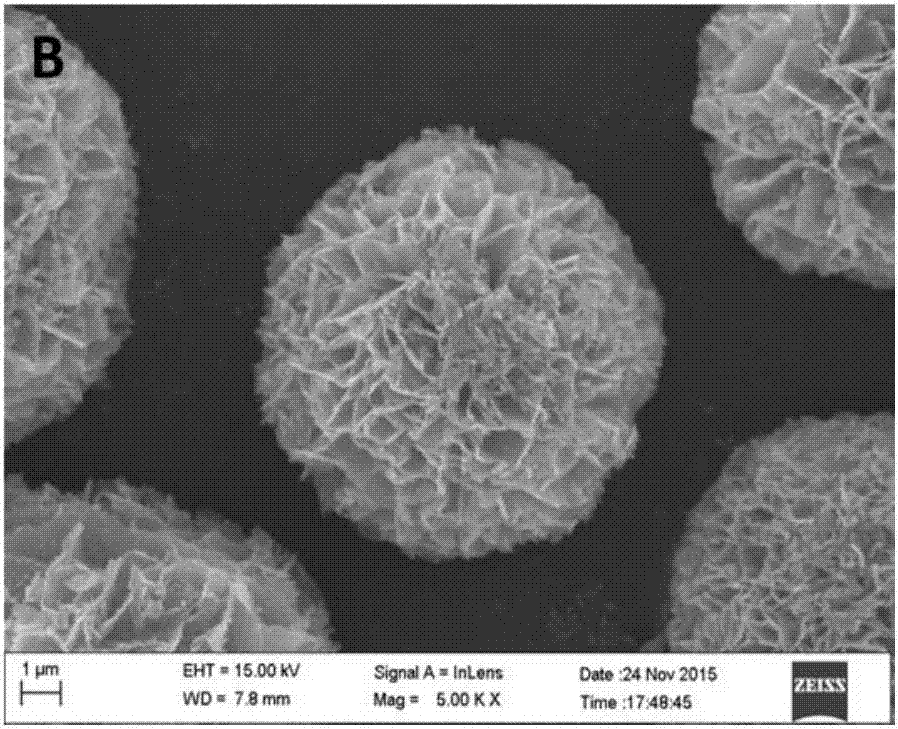

[0067] Follow the steps below to prepare micro-nanoparticles:

[0068] 1) Synthesis of flower-like vanadium oxide precursors formed by self-assembly of nanosheets:

[0069] 1.1) Add commercial vanadium pentoxide into ethylene glycol solution, and vigorously stir in a water bath at 60° C. for 2 hours to make it evenly mixed to form a suspension A; the molar concentration of the suspension A is 0.15 mM;

[0070] 1.2) Add 5 mL of sodium bicarbonate solution to the suspension A, so that the color of the suspension changes from brownish yellow to light yellow to form suspension B, wherein the molar concentration of the sodium bicarbonate solution is 1.25M;

[0071] 1.3) Put the suspension B into an autoclave and heat it at 220°C for 24 hours. After standing at room temperature and cooling, the precursor containing black precipitate can be obtained;

[0072] 1.4) Centrifuge the product mixed solution containing precipitate formed in step 1.3) at a centrifugal speed of 2000-3000 rpm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com