Antistatic ceramic tile prepared from fly ash and preparation method thereof

A fly ash, anti-static technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further described below in conjunction with embodiment.

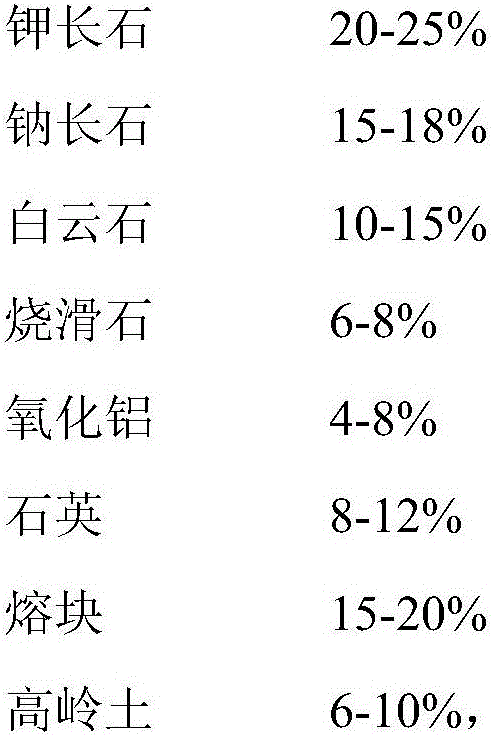

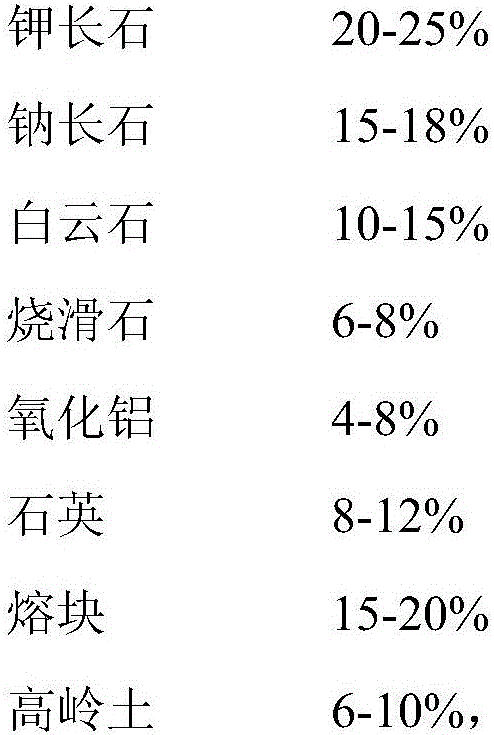

[0048] The chemical weight percentage composition of the raw materials used is shown in Table 1.

[0049] The chemical weight percentage composition of the raw materials used in Table 1

[0050]

SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

65.33

19.66

0.02

0.06

0.04

10.80

3.32

0.68

72.33

15.38

0.07

0.69

0.13

2.01

8.77

0.38

29.6

20.5

49

burning talc

64.3

34.06

Aluminum oxide

99.9

Kaolin

52.5

38.23

8.40

99.20

0.09

0.70

white clay

71.42

14.91

0.7

0.06

1.77

3.18

1.22

0.55

6.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com