Preparation method for mung bean protein with effect of reducing blood fat

A mung bean protein and blood lipid-lowering technology, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of acid-base waste and complicated operation, and achieve low price, simple extraction process and low technical requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 mung bean protein crude extract

[0045] The effects of extraction temperature, extraction time, solid-liquid ratio and ammonium sulfate concentration ratio on the extraction of mung bean protein were studied respectively.

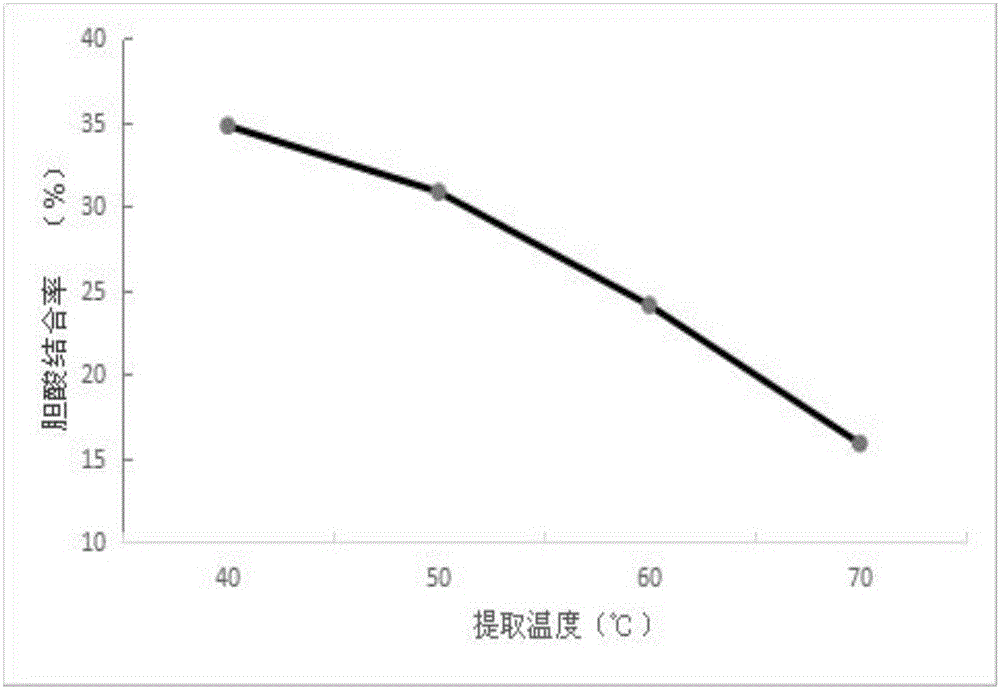

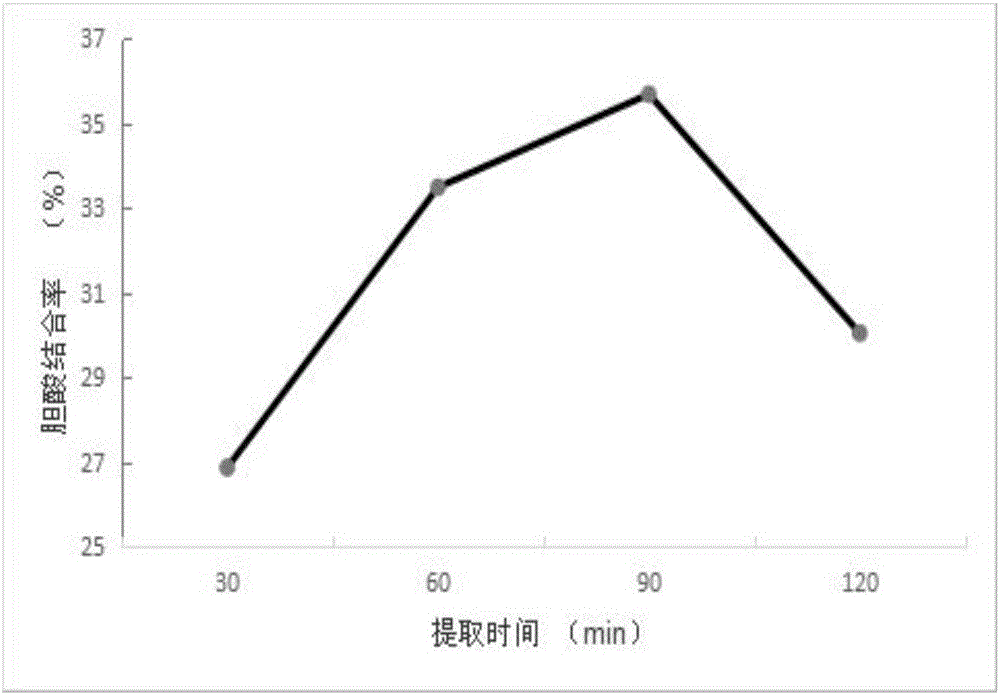

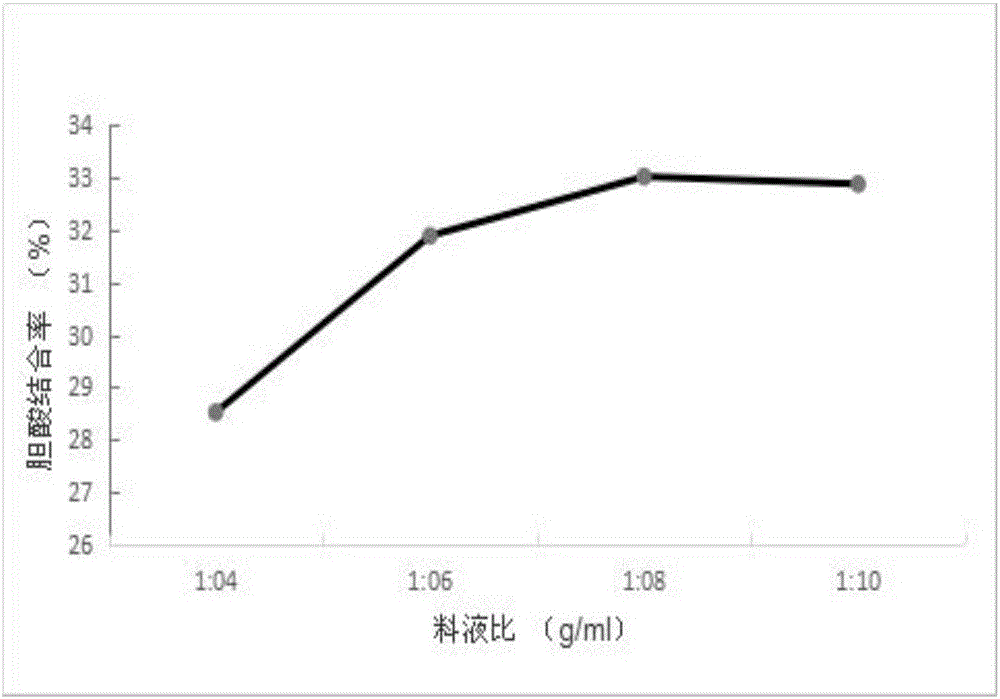

[0046] (1) Effects of extraction temperature, extraction time and ratio of solid to liquid on the extraction amount of mung bean protein.

[0047] Accurately weigh 50g of mung beans and crush them, pass through an 80-mesh sieve, soak with petroleum ether at a solid-to-liquid ratio of 1:2 for 1 day to degrease, and dry. Put the dried sample into a 100mL beaker, add pH7.0 phosphate buffer solution, and centrifuge to collect the supernatant after stirring and extracting for a certain period of time at a certain extraction temperature according to a certain solid-to-liquid ratio.

[0048] Investigate the ratio of solid to liquid 1:4, 1:6, 1:8, 1:10; and extraction time 40°C, 50°C, 60°C, 70°C; stirring extraction time 30m...

Embodiment 2

[0057] Example 2 Static adsorption confirms the optimum pH value of the ion-exchange chromatography buffer system

[0058] Add a certain amount of DEAE-Sepharose FF medium and a certain volume of phosphate buffer solution with a pH value, stir well and let it stand for 15 minutes, absorb the supernatant, and repeat 3 times. Add the same volume of phosphate buffer to the chromatographic medium and wait for balance, then add a certain volume of mung bean crude extract with a known concentration, stir and absorb fully, let stand for 30 minutes, and measure the content of the supernatant by the Coomassie brilliant blue method. protein content.

[0059] Select phosphate buffer solutions with pH values of 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, and 9.0, respectively, and perform static adsorption method. After standing for 30 minutes, measure the protein content in the supernatant, and compare different pH values. Effects on Media Adsorbed Proteins.

[0060] Adsorption rate / %=(ρ...

Embodiment 3

[0065] Embodiment 3 mung bean protein anion exchange chromatography

[0066] (1) Take DEAE-Sepharose FF (manufactured by GE, product number 17-0709-01) as a filler, pack it into a column, and elute with a pH7.5 phosphate buffer solution at a flow rate of 0.5ml / min, and elute overnight until the test line is balanced.

[0067] (2) Dissolve the crude mung bean protein extract in water, centrifuge at 12000r and put it on the column, elute with pH7.5 phosphate buffer solution for 1 times the column volume, and then elute with 0-2N sodium chloride solution gradient for 2-3 times the column volume. The phosphate is a mixed solution of disodium hydrogen phosphate and sodium dihydrogen phosphate. The elution flow rate is: 2ml / min, and the eluent is 4ml / bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com