A method for continuous production of polyethylene wax by thermal cracking in an externally rotating self-stirring reactor

A polyethylene wax and self-stirring technology, which is applied in the field of polymer materials, can solve the problems of easily damaged stirring devices or extrusion devices, high labor intensity of workers, and inability to continuously produce, etc., and achieves short cracking cycle, low production cost, and low manufacturing cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

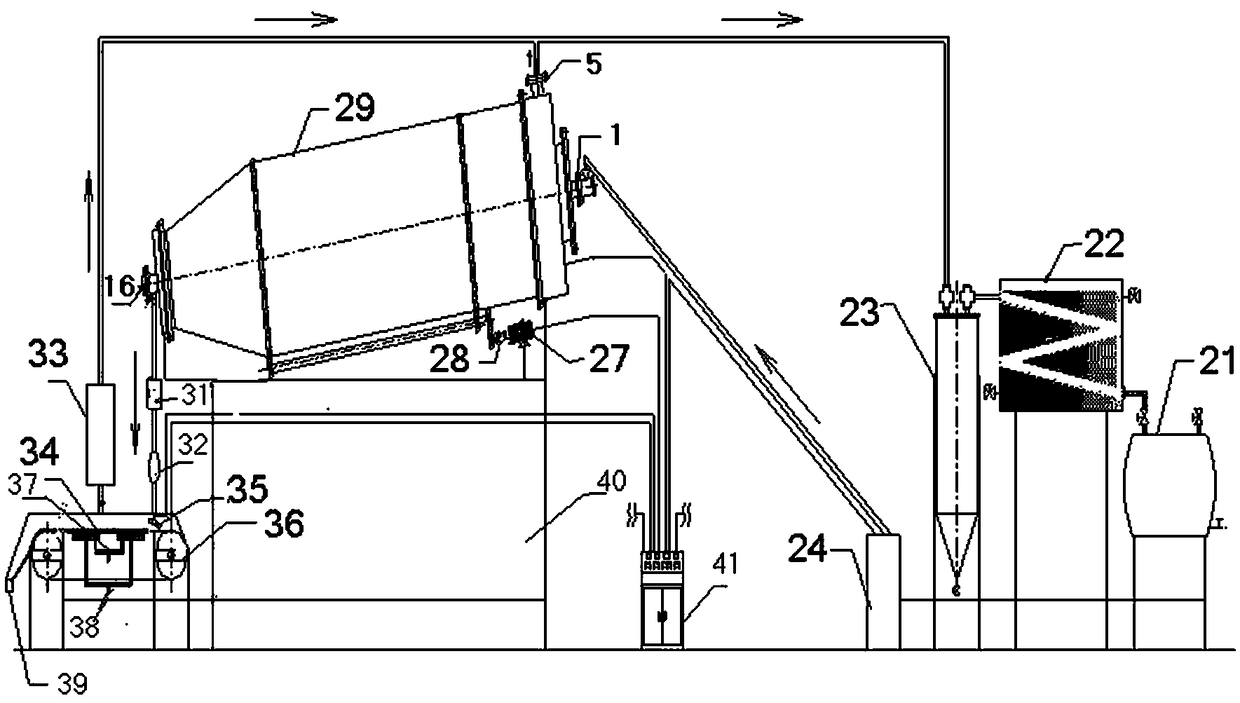

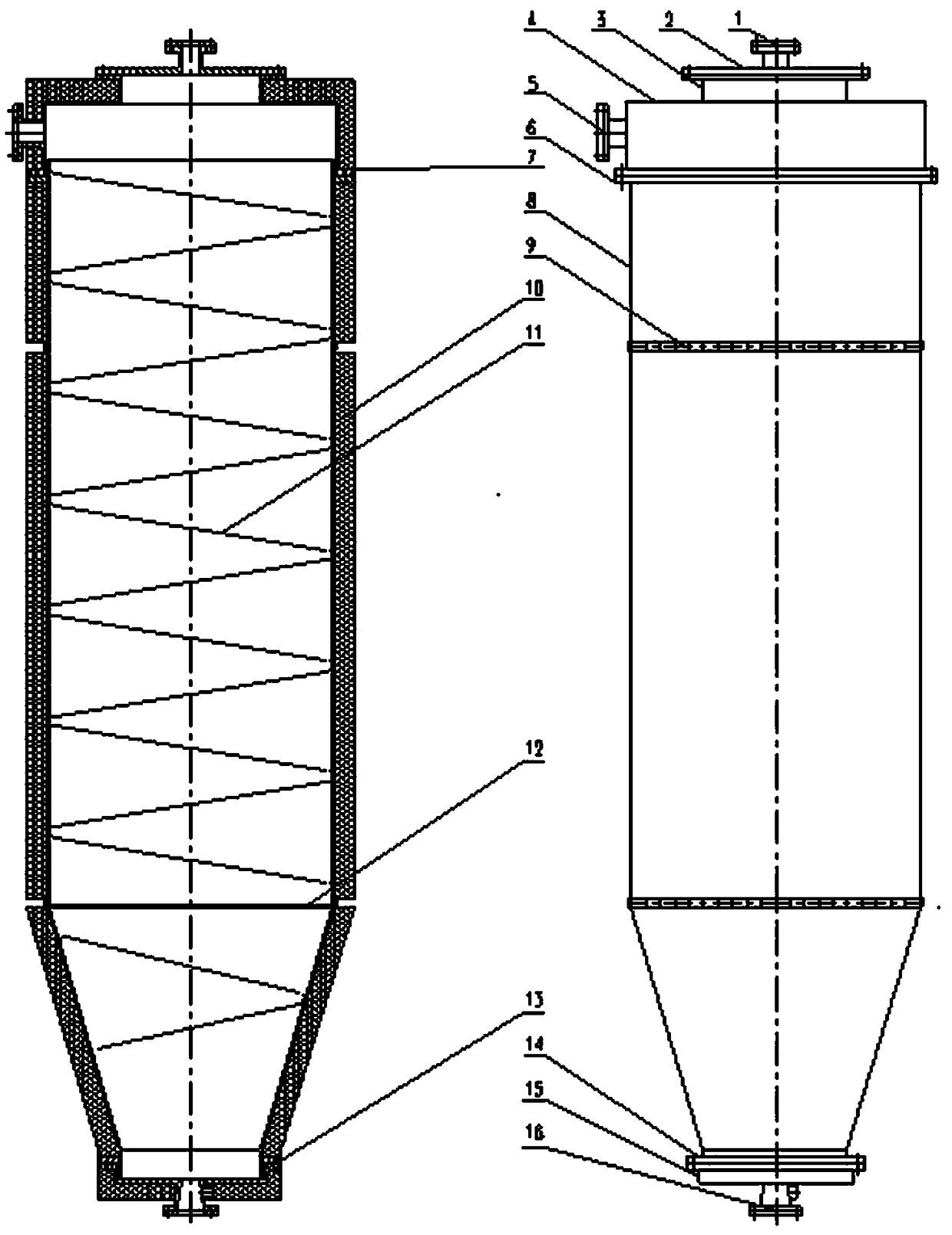

Method used

Image

Examples

Embodiment 1

[0028]Firstly, the waste PE is sorted, cleaned and dried for pretreatment, and the pretreated waste PE is evenly sent into the external rotating self-stirring reactor through a fully automatic feeder, and the catalyst Al-MCM-48 is mixed and added, and the catalyst Al-MCM- 48 The amount added is 0.1% of the weight of waste PE, and the reactor is closed. Then turn on the electric heater of the external rotating self-stirring reactor to heat, stir while heating, and heat up to the cracking temperature of 300±5°C. After 10 minutes, the temperature is accurately controlled by the temperature sensor and kept at a constant temperature of 290±5°C for 4 hours, then stop heating. Then it goes through the continuous discharge filter system to cool down and enters the distributor for direct granulation, and then it is cooled to obtain spherical or flake polyethylene wax. The yield of this method reaches 94% to 96%. When the temperature of the product dropped to room temperature, it was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com