Sizing agent composition for ramie fabric and preparing method and application thereof

A composition and fabric technology, applied in the directions of plant fibers, textiles and papermaking, improved hand-feeling fibers, etc., can solve the problems of difficult operation, inconvenient for industrial production, and laboratory experiments, and achieve good permeability and improve sizing. Good performance, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

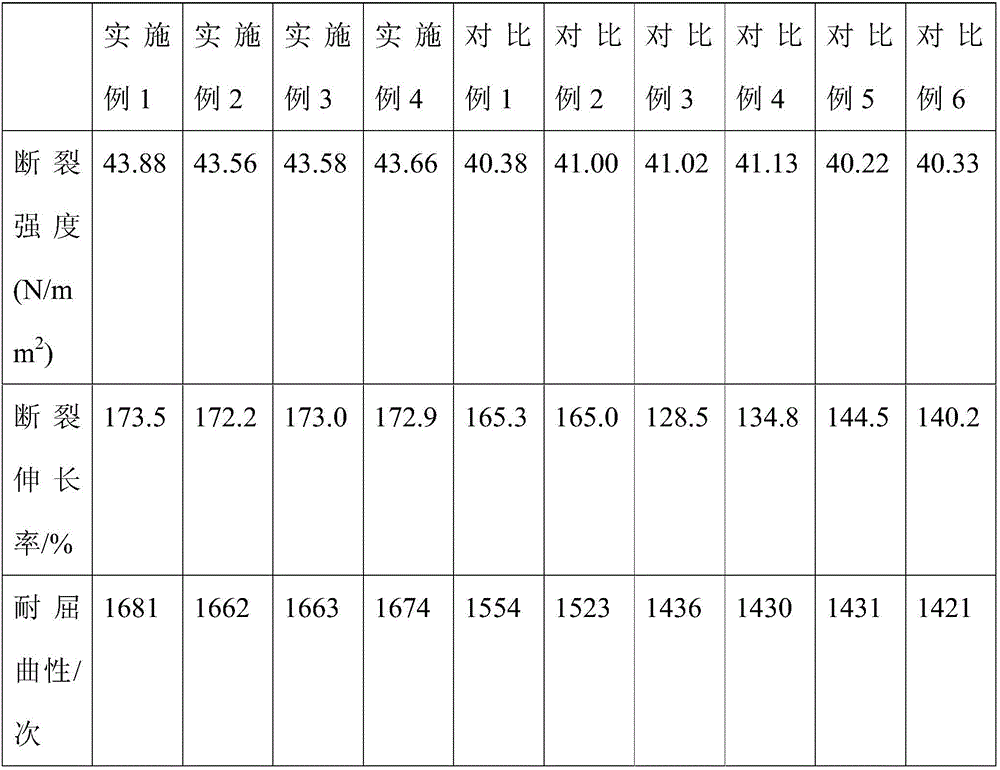

Examples

Embodiment 1

[0046] (1) Preparation of solid acrylate:

[0047] Add 100kg of hydrogenated polybutadiene di(meth)acrylate, 150kg of 1-adamantane (meth)acrylate and 250kg of methacrylic acid-2-ethyl sulfonate into the head tank, stir evenly and set aside;

[0048] Add 200kg of xylene, 100kg of cyclohexane, and 100kg of absolute ethanol to a 1000L high-level tank with stirring, mix well, weigh 5.6kg of benzoyl peroxide and 2.8kg of azobisisobutyronitrile and put them into the high-level tank respectively, and stir Uniform spare;

[0049] Add 1400kg of toluene, 700kg of cyclohexane, and 700kg of absolute ethanol in turn to the 5000L glass-lined reactor equipped with a reflux condenser and mix them uniformly as a solvent for the reaction, then add 0.1kg of xanthate, 0.2kg of sodium bisulfite and Stir 0.1kg of n-dodecanethiol evenly, raise the temperature to 95°C, and drop the monomers and initiators in the above two high level tanks into the 5000L reaction kettle at the same time, and the addi...

Embodiment 2

[0055] (1) Preparation of solid acrylate:

[0056] Add 200kg of hydrogenated polybutadiene di(meth)acrylate, 100kg of 1-adamantane (meth)acrylate and 200kg of methacrylic acid-2-ethyl sulfonate into the head tank, stir evenly for later use;

[0057] Add 200kg of xylene, 100kg of cyclohexane, and 100kg of absolute ethanol to a 1000L high-level tank with stirring, mix well, weigh 5.6kg of benzoyl peroxide and 2.8kg of azobisisobutyronitrile and put them into the high-level tank respectively, and stir Uniform spare;

[0058] Add 1400kg of toluene, 700kg of cyclohexane, and 700kg of absolute ethanol in turn to the 5000L glass-lined reactor equipped with a reflux condenser and mix them uniformly as a solvent for the reaction, then add 0.2kg of xanthate, 0.1kg of sodium bisulfite and Stir 0.1kg of n-dodecanethiol evenly, raise the temperature to 95°C, and drop the monomers and initiators in the above two high level tanks into the 5000L reaction kettle at the same time, and the addi...

Embodiment 3

[0064] (1) Preparation of solid acrylate:

[0065] Add 120kg hydrogenated polyisoprene di(meth)acrylate, 170kg norbornyl (meth)acrylate and 210kg methacrylic acid-2-ethyl sulfonate into the head tank, stir evenly for subsequent use;

[0066]Add 200kg of xylene, 100kg of cyclohexane, and 100kg of absolute ethanol to a 1000L high-level tank with stirring, mix well, weigh 5.6kg of benzoyl peroxide and 2.8kg of azobisisobutyronitrile and put them into the high-level tank respectively, and stir Uniform spare;

[0067] Add 1400kg of toluene, 700kg of cyclohexane, and 700kg of absolute ethanol in turn to the 5000L glass-lined reactor equipped with a reflux condenser and mix them uniformly as a solvent for the reaction, then add 0.1kg of xanthate, 0.2kg of sodium bisulfite and Stir 0.1kg of n-dodecanethiol evenly, raise the temperature to 95°C, and drop the monomers and initiators in the above two high level tanks into the 5000L reaction kettle at the same time, and the addition is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com