Silicon infrared optical detector structure and manufacturing method therefor

A manufacturing method and photodetector technology, applied in photovoltaic power generation, semiconductor devices, final product manufacturing, etc., can solve the problems of shortening the lifetime of non-equilibrium carriers, not easy to ionize, and difficult to control the energy level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

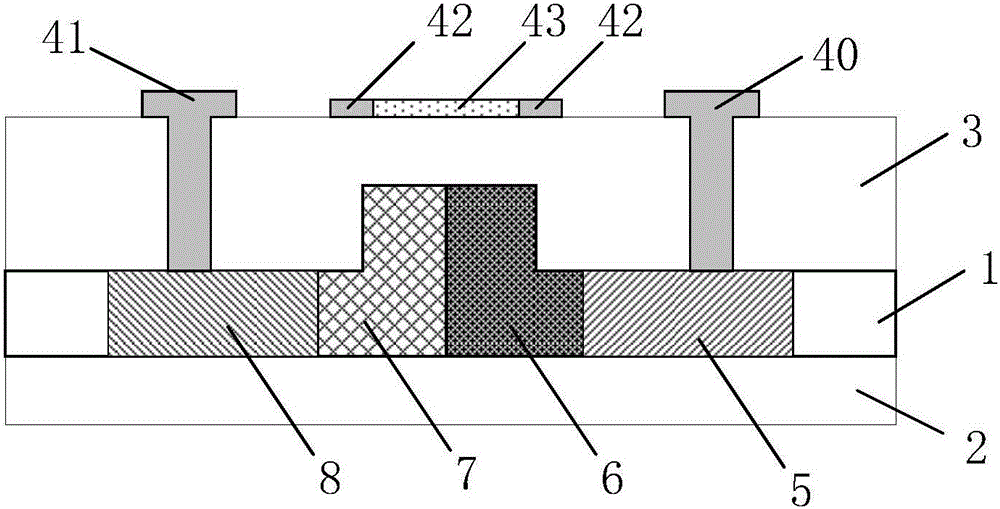

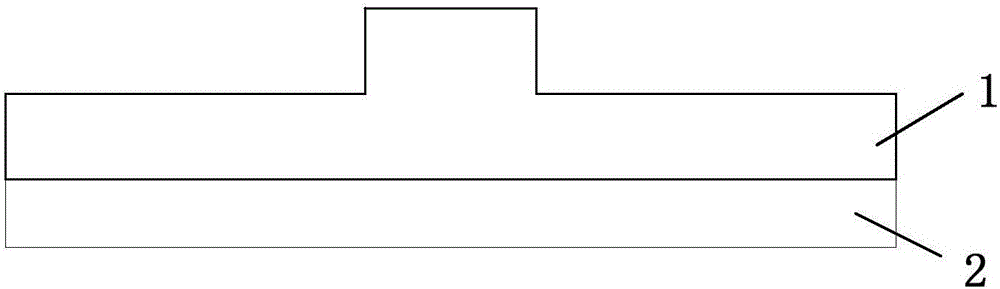

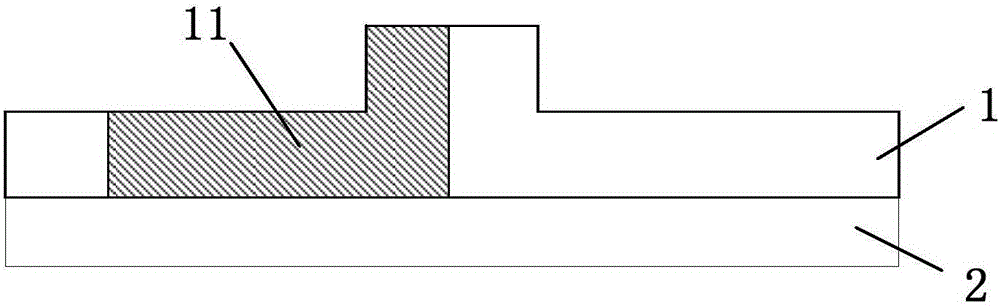

[0055] Such as figure 1 Shown: the structure of the silicon infrared photodetector of the present invention comprises a dielectric layer 2, a single crystal silicon layer 1 and a passivation layer 3 arranged in sequence from bottom to top, and a resistance heater is arranged on the surface of the passivation layer 3, and the resistance heating The device includes the electrode 42 of the resistance heater and the resistance part 43 of the resistance heater; the upper surface of the single crystal silicon layer 1 is etched to form a ridge-shaped optical waveguide, and the single crystal silicon layer 1 is provided with a re-donor compensation Superheavy acceptor doped region (P ++ N +) 7, superheavy donor doped region with heavy acceptor compensation (N++P+) 6, superheavy acceptor doped region (P++) 8 and superheavy donor doped Region (N++) 5, superheavy acceptor doped region (P ++ N + ) 7 with heavy donor compensation and superheavy donor doped region (N++P+) 6 with heavy accep...

Embodiment 2

[0075] Such as Figure 15 Shown: the structure of the silicon infrared photodetector of the present invention includes a single crystal silicon substrate 10, and the upper surface of the single crystal silicon substrate 10 is etched to form a ridge-shaped optical waveguide; on the single crystal silicon substrate 10 The upper surface is covered with a passivation layer 3, and the passivation layer 3 evenly covers the ridge optical waveguide and the two wings of the ridge optical waveguide; in the single crystal silicon substrate 10, a superheavy acceptor doped region ( P ++ N +) 7, super heavy donor doped region with heavy acceptor compensation (N++P+) 6, super heavy acceptor doped region (P++) 8, super heavy donor doped region (N ++) 5 and heavy Acceptor doped region (P+)9, superheavy acceptor doped region with heavy donor compensation (P++N+)7 and superheavy donor doped region with heavy acceptor compensation (N++P+)6 Arranged along the side walls and top of the ridge optic...

Embodiment 3

[0084] Such as Figure 21Shown: the structure of the silicon infrared detector of the present invention, including a dielectric layer 2, a single crystal silicon layer 1 and a passivation layer 3 arranged in sequence from bottom to top, and the upper surface of the single crystal silicon layer 1 is etched to form a ridge Shaped optical waveguide, the superheavy acceptor doped region (P ++ N + ) 7, the superheavy acceptor doped region (P++) 8 and the heavy donor doped region ( N+) 15, superheavy acceptor doped region (P++ N+) 7 with heavy donor compensation located in the region of the ridge optical waveguide, superheavy acceptor doped region (P++) 8 and heavy donor doped region (N+ ) 15 are located on the two wings of the ridge optical waveguide; the upper surface of the passivation layer 3 is close to a plane, and an N-type electrode 40 and a P-type electrode 41 are arranged in the passivation layer 3, the N-type electrode 40 is the cathode of the detector, and the P The N-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com