Modulation-doped multi-period strain-compensated quantum well epitaxial layer and growth method thereof

A technology of strain compensation and modulation doping, which is applied in the direction of phonon exciters, laser components, electrical components, etc., can solve the problems affecting the luminous efficiency of quantum wells, lattice relaxation, and the quality of epitaxial growth of large-strain multi-period quantum well materials Difficulties and other problems, to achieve the effect of improving external quantum efficiency, reducing Auger recombination, and increasing relaxation oscillation frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

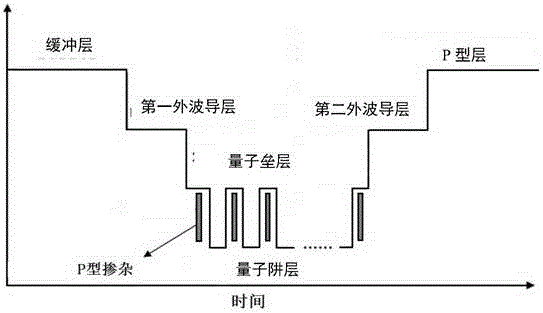

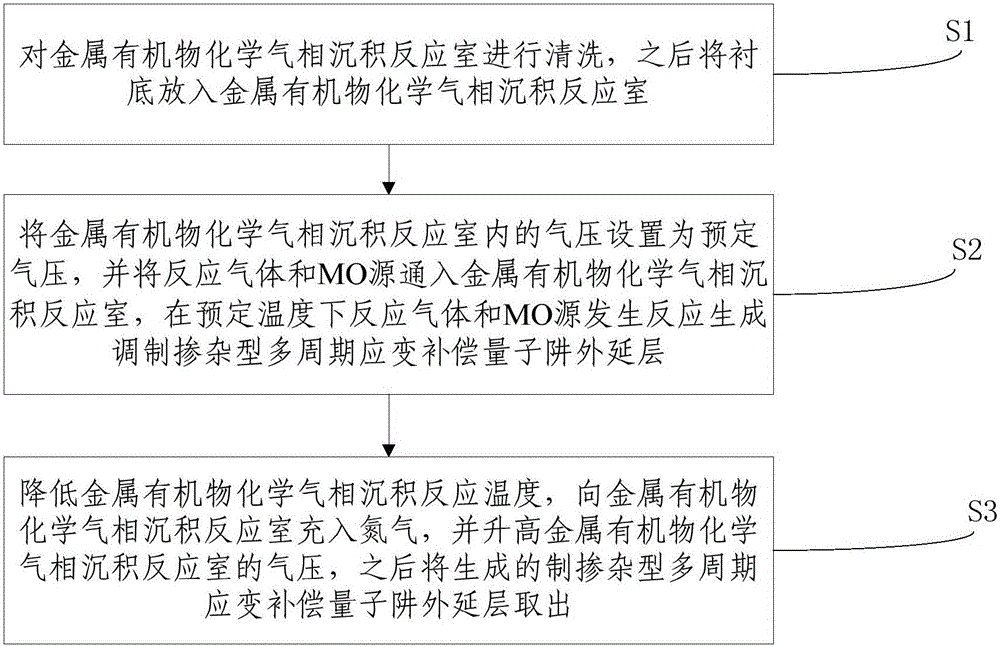

[0040] A modulation doped multi-period strain compensation quantum well epitaxial layer growth method, such as figure 1 As shown, the method includes the following steps:

[0041] S1. Baking and cleaning the metal-organic chemical vapor deposition MOCVD reaction chamber to remove foreign matter on the surface, and then placing the substrate on the base of the metal-organic chemical vapor deposition reaction chamber MOCVD; wherein the substrate is an InP substrate Bottom, the baking temperature is 740 degrees;

[0042] S2. Set the pressure in the metal-organic chemical vapor deposition reaction chamber to a predetermined pressure, and pass the reaction gas and the MO source into the metal-organic chemical va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com