Method for improving mechanical properties of polycaprolactone-based biological elastomer

A technology of elastomer and caprolactone, which is used in prosthesis, medical science and other directions, can solve the problems of limited application and poor mechanical properties, and achieve the effect of wide application range, good curing molding method and high tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] What the present embodiment provides is the preparation of BDM-PMCL different molecular weight prepolymers, the preparation method is with reference to prior patent application CN103626979A[0038], compared with prior patent application, the change is that terephthalyl dimethanol (BDM, initiator ) and 4-methyl-ε-caprolactone (MeCL), the molar ratios of initiator to monomer were 1:50, 1:100, 1:200, 1:250, 1:300, 1:400 ; That is, in the present embodiment, the degree of polymerization n is 50, 100, 200, 250, 300, and 400, respectively, and six gradients are used to obtain the BDM-PMCL prepolymer Ia.

[0041] The end group modification method refers to the prior patent application CN103626979A [0038] to obtain the BDM-PMCL prepolymer Ib, and the composition is shown in Table 1 below.

[0042] Table 1 Synthesis and component characterization of polycaprolactone-based linear prepolymer

[0043]

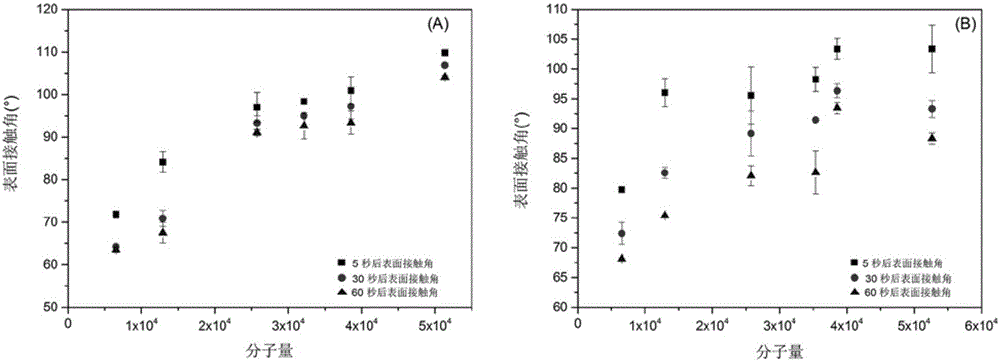

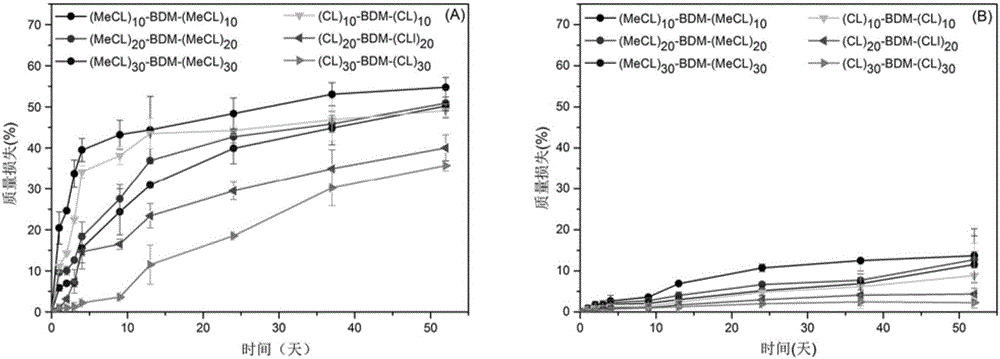

[0044]The BDM-PMCL prepolymer Ib prepared in this embodiment is compared wit...

Embodiment 2

[0050] What the present embodiment provides is the preparation of 4s-PE-PMCL prepolymer, and preparation method refers to prior patent application CN103626979A [0038], changes initiator into pentaerythritol, and changes pentaerythritol (PE) and 4-methyl-ε- The molar ratios of caprolactone (MeCL) are 1:50, 1:100, 1:200, 1:250, 1:300, 1:400 respectively, and the degree of polymerization n is 50, 100, 200 respectively in this embodiment , 250, 300, 400 six gradients to get 4s-PE-PMCL prepolymer IIa.

[0051] The terminal group modification method refers to the prior patent application CN103626979A [0038] to obtain BDM-PMCL prepolymer IIb, and the composition is shown in the following table.

[0052] Table 2 Synthesis and component characterization of polycaprolactone-based star prepolymer

[0053]

[0054] Compared with the corresponding product obtained in the previous patent application CN103626979A, "Synthesis and application of amorphous polyester based on 4-methyl-ε-capr...

Embodiment 3

[0060] This embodiment relates to a method for preparing a bioelastomer with high mechanical properties, comprising the following steps:

[0061] According to the method described in Example 1, prepolymers with different molecular weights are obtained, which are abbreviated as: a: BDM-PMCL 50 , b: BDM-PMCL 100 , c: BDM-PMCL 200 , d: BDM-PMCL 250 , e: BDM-PMCL 300 , f: BDM-PMCL 400 .

[0062] Add photoinitiator (benzoin dimethyl ether) respectively in above-mentioned six kinds of prepolymers, photoinitiator and prepolymer molar ratio are 1:20, add tetrafluoroethylene template after mixing, with 500W, 365nm ultraviolet light The six kinds of cross-linked polymer samples with fixed sizes were obtained by light irradiation for 10 min respectively. National standard sample preparation was adopted to prepare dumbbell-shaped specimens, and the mechanical properties were tested with a universal testing machine, and the tensile test was carried out at room temperature. The resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com