Aged grain rice compound fermented feed and production and preparation method thereof

A composite fermentation and mixed fermentation technology, applied in animal feed, animal feed, application and other directions, can solve the problems of difficult to reflect nutritional value, excessive Aspergillus flavus, poor palatability, etc., to alleviate the pressure and practicability of poultry health hazards Strong, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

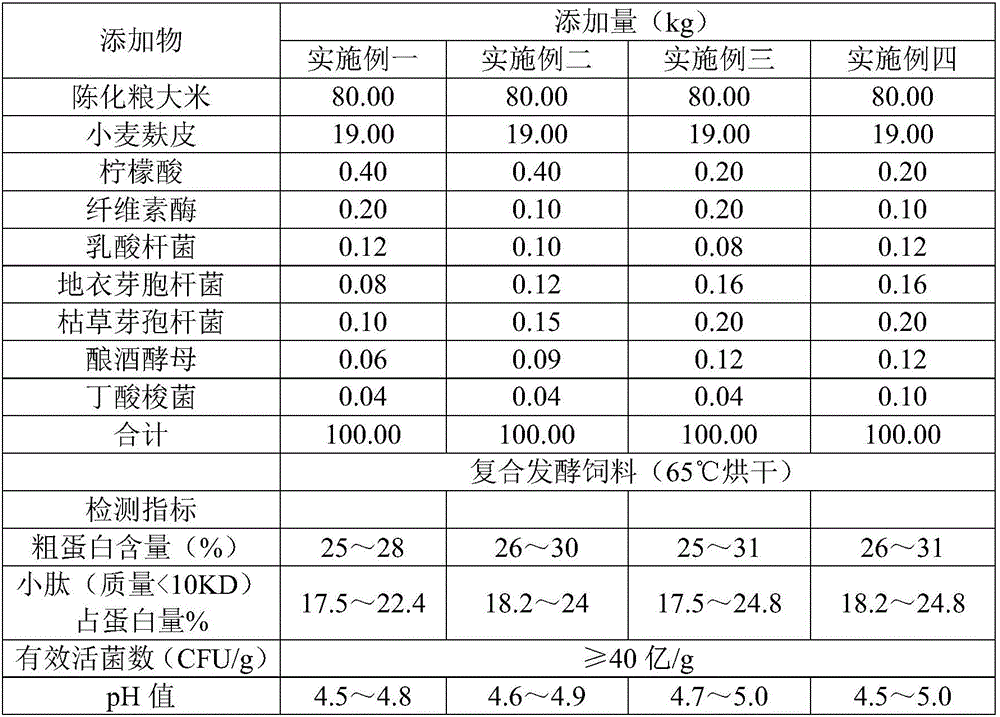

Examples

preparation example Construction

[0022] First of all, it should be explained that the present invention not only provides an aged grain and rice compound fermented feed, but also provides a production and preparation method of the aged grain and rice compound fermented feed. Among them, the production and preparation method of aged grain rice compound fermented feed specifically includes the following steps:

[0023] 1. Dehulling the aged grain rice to obtain the aged grain rice, and performing preliminary crushing treatment on the aged grain rice;

[0024] 2. Carry out secondary crushing and sieving treatment to the aged grain rice after the primary crushing, and obtain the aged grain rice flour meeting the requirements as the main ingredient of fermentation raw material;

[0025] 3. Crushing and sieving the wheat bran to obtain the wheat bran powder meeting the requirements, as a fermentation raw material auxiliary material;

[0026] 4. Weigh the aged grain rice flour obtained in step 2 and the wheat bran ...

Embodiment 1

[0037]Dehulling the aged grain rice to obtain the aged grain rice, and performing preliminary crushing treatment on the aged grain rice; performing secondary crushing on the aged grain rice after the primary crushing, and passing through a 40-60 mesh sieve Processing, to obtain the aging grain rice flour that meets the requirements, as the main ingredient of fermentation raw materials.

[0038] Wheat bran is pulverized and sieved through 40-60 meshes to obtain wheat bran powder meeting requirements, which is used as an auxiliary material for fermentation.

[0039] 80.00 kg of aged rice flour and 19.00 kg of wheat bran powder were weighed and mixed respectively to obtain mixed fermentation raw materials.

[0040] 0.12 kg of Lactobacillus, 0.08 kg of Bacillus licheniformis, 0.10 kg of Bacillus subtilis, 0.06 kg of Saccharomyces cerevisiae and 0.04 kg of Clostridium butyricum were weighed and mixed to obtain mixed strains. Among them, the effective number of live bacteria of Lac...

Embodiment 2

[0045] Dehulling the aged grain rice to obtain the aged grain rice, and performing preliminary crushing treatment on the aged grain rice; performing secondary crushing on the aged grain rice after the primary crushing, and passing through a 40-60 mesh sieve Processing, to obtain the aging grain rice flour that meets the requirements, as the main ingredient of fermentation raw materials.

[0046] Wheat bran is pulverized and sieved through 40-60 meshes to obtain wheat bran powder meeting requirements, which is used as an auxiliary material for fermentation.

[0047] 80.00 kg of aged rice flour and 19.00 kg of wheat bran powder were weighed and mixed respectively to obtain mixed fermentation raw materials.

[0048] 0.10 kg of Lactobacillus, 0.12 kg of Bacillus licheniformis, 0.15 kg of Bacillus subtilis, 0.09 kg of Saccharomyces cerevisiae and 0.04 kg of Clostridium butyricum were weighed and mixed to obtain mixed strains. Among them, the effective number of live bacteria of La...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com