A kind of flushing emulsion for wet electrostatic precipitator and preparation method thereof

A wet electrostatic precipitator and emulsion technology, which is applied in the field of washing emulsion, can solve the problems of single purpose and unsatisfactory effect, and achieve the effects of low production cost, excellent material selection, and improved gas-liquid mass transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

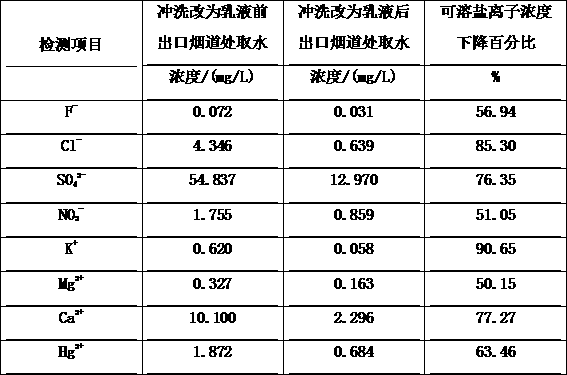

Embodiment 1

[0031] The flushing emulsion for a wet electric precipitator described in this embodiment includes the following components by weight percentage:

[0032] Solvent 7%

[0033] Surfactant 2%

[0034] Additive 0.6%

[0035] NaOH 2%

[0036] Deionized water balance.

[0037] The solvent is made by mixing and stirring oleic acid and acrylic acid at a temperature of 60° C. and a pressure of 0.6 MPa for 5 minutes, and the weight percentage of the oleic acid and acrylic acid is 68% and 32%.

[0038] The surfactant is composed of cetyltrimethylammonium bromide, C12 fatty alcohol polyoxyethylene (9) ether, and sodium lauryl sulfate mixed and stirred in the reactor for 7 minutes. The bottom of the kettle is filled with oxygen for 1 minute, and the oxygen filling amount is 4 liters / min. The weight percentages of the cetyltrimethylammonium bromide, C12 fatty alcohol polyoxyethylene (9) ether, and sodium lauryl sulfate are 30%:40%:30%.

[0039] The additives are made by mixing and stirring sodium benz...

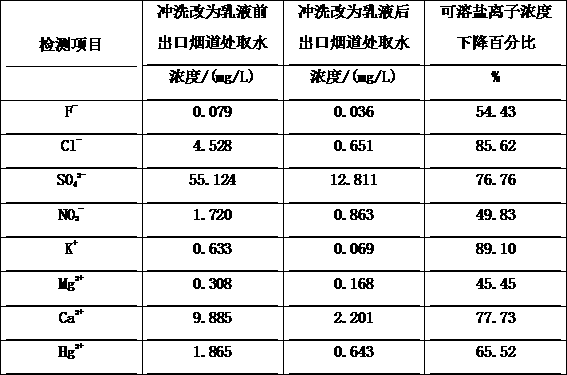

Embodiment 2

[0057] The flushing emulsion for a wet electrostatic precipitator described in this embodiment includes the following components by weight percentage:

[0058] Solvent 5%

[0059] Surfactant 2%

[0060] Additive 0.5%

[0061] NaOH 3%

[0062] Deionized water balance.

[0063] The solvent is made by mixing and stirring oleic acid and acrylic acid at a temperature of 55° C. and a pressure of 0.8 MPa for 4 minutes, and the weight percentage of the oleic acid and acrylic acid is 70% and 30%.

[0064] The surfactant is made of cetyltrimethylammonium bromide, C12 fatty alcohol polyoxyethylene (9) ether, and sodium lauryl sulfate mixed and stirred in the reaction kettle for 8 minutes. The bottom of the kettle is filled with oxygen for 1 minute, and the oxygen filling amount is 4 liters / minute. The weight percentages of the cetyltrimethylammonium bromide, C12 fatty alcohol polyoxyethylene (9) ether, and sodium lauryl sulfate are 29%:44%:27%.

[0065] The additives are made by mixing and stirring...

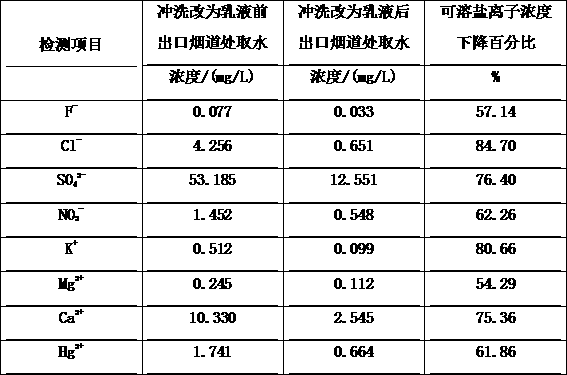

Embodiment 3

[0083] The flushing emulsion for a wet electrostatic precipitator described in this embodiment includes the following components by weight percentage:

[0084] Solvent 10%

[0085] Surfactant 1%

[0086] Additive 0.8%

[0087] NaOH 1%

[0088] Deionized water balance.

[0089] The solvent is made by mixing and stirring oleic acid and acrylic acid at a temperature of 65° C. and a pressure of 0.5 MPa for 6 minutes, and the weight percentage of the oleic acid and acrylic acid is 70% and 30%.

[0090] The surfactant is composed of cetyltrimethylammonium bromide, C12 fatty alcohol polyoxyethylene (9) ether, and sodium lauryl sulfate mixed and stirred in the reaction kettle for 5 minutes. The bottom of the kettle is filled with oxygen for 2 minutes, and the oxygen filling amount is 3 liters / min. The weight percentages of the cetyltrimethylammonium bromide, C12 fatty alcohol polyoxyethylene (9) ether, and sodium lauryl sulfate are 32%: 37%: 31%.

[0091] The additive is made by mixing and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com