Anti-oxidation material and preparation method thereof

An anti-oxidation, a certain amount of technology, applied in the direction of polyether coatings, coatings, etc., can solve the problem of increasing the content of harmful substances, and achieve the effects of inhibiting oxidation reactions, good chemical stability and mechanical strength, and high-efficiency anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

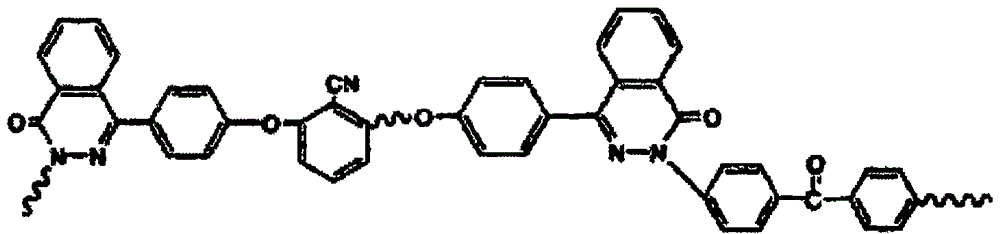

Method used

Image

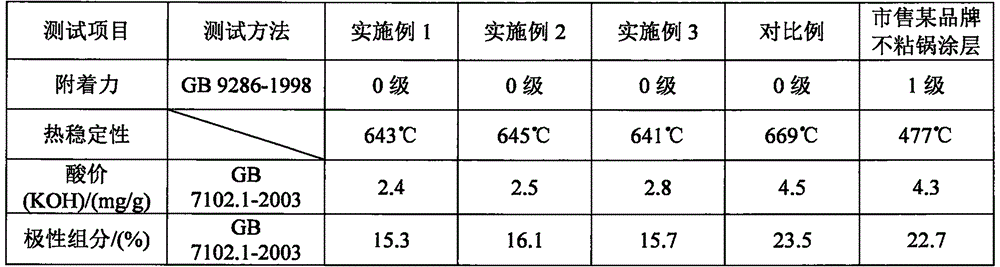

Examples

Embodiment 1

[0027] An antioxidant material is provided, prepared by the following method:

[0028] (1) Heating 100 parts by mass of polyarylether nitrile ketone to 120°C, dehydrating under reduced pressure for 90 minutes, removing the remaining moisture in the raw materials, and then reducing the system temperature to normal temperature;

[0029] (2) Dissolve 20 parts by mass of astaxanthin in 100 parts by mass of dimethylformamide that has been distilled to remove water, and then add the polyarylether nitrile ketone obtained in step (1) to the aforementioned solution Mix evenly, and react at 50°C for 120 minutes to obtain the first reactant;

[0030] (3) Add 10 parts by mass of silane coupling agent KH792 to the first reactant, and react at 50° C. for 60 minutes to obtain the second reactant;

[0031] (4) the methyl triethoxysilane of 5 mass parts, the methyl tert-butyl ether of 20 mass parts, the azodicarbonamide of 3 mass parts, the diphenyldimethoxysilane of 20 mass parts, 30 parts ...

Embodiment 2

[0034] An antioxidant material is provided, prepared by the following method:

[0035] (1) Heating 150 parts by mass of polyarylether nitrile ketone to 80°C, dehydrating under reduced pressure for 150 minutes, removing the remaining moisture in the raw materials, and then lowering the system temperature to normal temperature;

[0036] (2) Dissolve 10 parts by mass of astaxanthin in 80 parts by mass of dimethylformamide that has been distilled to remove water, and then add the polyarylether nitrile ketone obtained in step (1) to the aforementioned solution Mix evenly, and react at 80°C for 60 minutes to obtain the first reactant;

[0037] (3) Add 20 parts by mass of silane coupling agent KH792 to the first reactant, and react at 80° C. for 30 minutes to obtain the second reactant;

[0038] (4) the methyl triethoxysilane of 10 mass parts, the methyl tert-butyl ether of 12 mass parts, the azodicarbonamide of 8 mass parts, the diphenyldimethoxysilane of 10 mass parts, 50 parts b...

Embodiment 3

[0041] An antioxidant material is provided, prepared by the following method:

[0042] (1) Heating 130 parts by mass of polyarylether nitrile ketone to 100°C, dehydrating under reduced pressure for 120 minutes, removing the remaining moisture in the raw materials, and then reducing the system temperature to normal temperature;

[0043] (2) Dissolve 15 parts by mass of astaxanthin in 90 parts by mass of dimethylformamide that has been distilled to remove water, and then add the polyarylether nitrile ketone obtained in step (1) to the aforementioned solution Mix evenly and react at 70°C for 100 minutes to obtain the first reactant;

[0044] (3) Add 15 parts by mass of silane coupling agent KH792 to the first reactant, and react at 70° C. for 50 minutes to obtain the second reactant;

[0045] (4) the methyl triethoxysilane of 8 mass parts, the methyl tert-butyl ether of 15 mass parts, the azodicarbonamide of 5 mass parts, the diphenyldimethoxysilane of 15 mass parts, 40 parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com