Method for preparing conducting polyaniline nanotubes with fructose as template

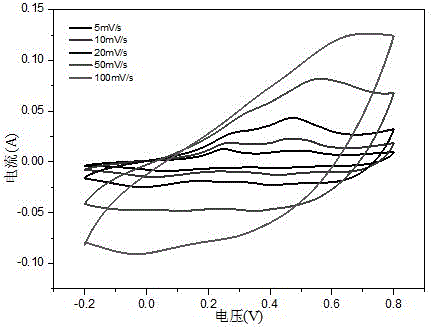

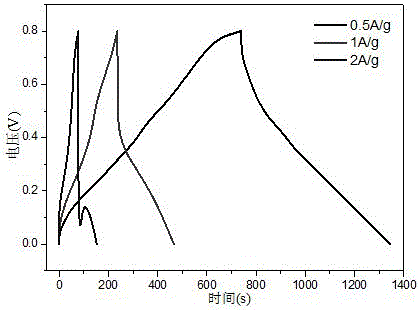

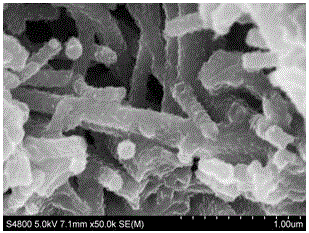

A conductive polyaniline and nanotube technology, applied in the field of conductive polymer material preparation, can solve the problems of irregularity, uncontrollable diameter of polyaniline nanotubes, affecting the electrochemical performance of polyaniline, etc. The effect of good electrochemical performance and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 0.132 g of fructose and add it to a flask containing 30 mL of deionized water, stir at room temperature for 0.5 h, then transfer the flask to an ice-water bath, then add 1 mL of aniline and 10 mL of 1 mol / L hydrochloric acid into the flask solution, stirred for 1 h under the condition of an ice-water bath to prepare a mixed solution, then added dropwise ammonium persulfate solution to the mixed solution, stirred for 12 h under the condition of an ice-water bath, and then the reactant was washed with deionized water, Suction filtration until the filtrate was neutral, the resulting filter cake was dried in a vacuum oven at 50 °C for 24 h, and collected by grinding to obtain conductive polyaniline nanotubes.

[0017] The molar ratio of fructose to aniline is 1:15; the molar ratio of ammonium persulfate to aniline is 1:1.

Embodiment 2

[0019] Weigh 0.164 g of fructose and add it to a flask containing 30 mL of deionized water, stir at room temperature for 0.5 h, then transfer the flask to an ice-water bath, then add 1 mL of aniline and 10 mL of 1 mol / L hydrochloric acid into the flask solution, stirred for 1 h under the condition of an ice-water bath to prepare a mixed solution, then added dropwise ammonium persulfate solution to the mixed solution, stirred for 12 h under the condition of an ice-water bath, and then the reactant was washed with deionized water, Suction filtration until the filtrate was neutral, the resulting filter cake was dried in a vacuum oven at 50 °C for 24 h, and collected by grinding to obtain conductive polyaniline nanotubes.

[0020] The substance ratio of fructose to aniline is 1:12; the substance ratio of ammonium persulfate to aniline is 1:1.

Embodiment 3

[0022] Weigh 0.219 g of fructose and add it to a flask containing 30 mL of deionized water, stir at room temperature for 0.5 h, then transfer the flask to an ice-water bath, then add 1 mL of aniline and 10 mL of 1 mol / L hydrochloric acid into the flask solution, stirred for 1 h under the condition of an ice-water bath to prepare a mixed solution, then added dropwise ammonium persulfate solution to the mixed solution, stirred for 12 h under the condition of an ice-water bath, and then the reactant was washed with deionized water, Suction filtration until the filtrate was neutral, the resulting filter cake was dried in a vacuum oven at 50 °C for 24 h, and collected by grinding to obtain conductive polyaniline nanotubes.

[0023] The substance ratio of fructose to aniline is 1:9; the substance ratio of ammonium persulfate to aniline is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com