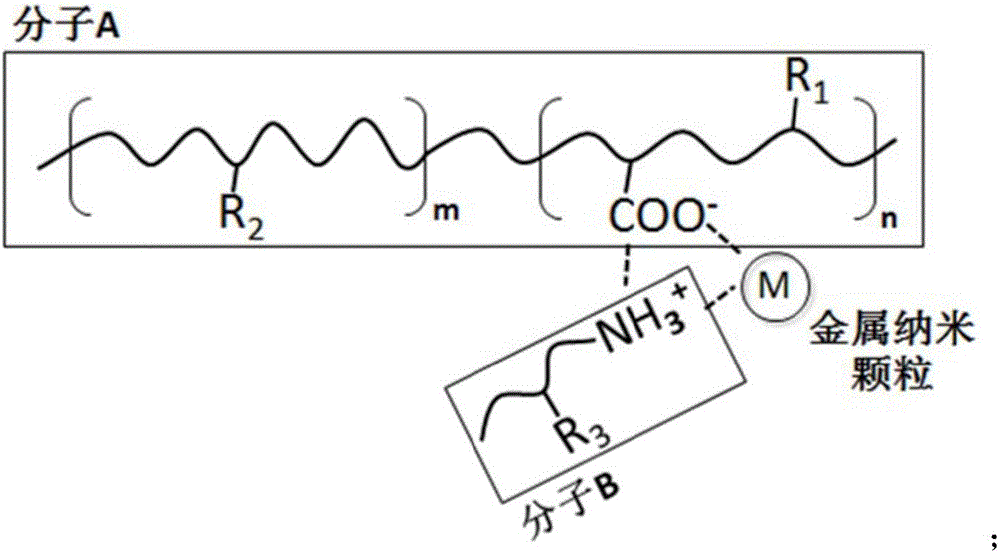

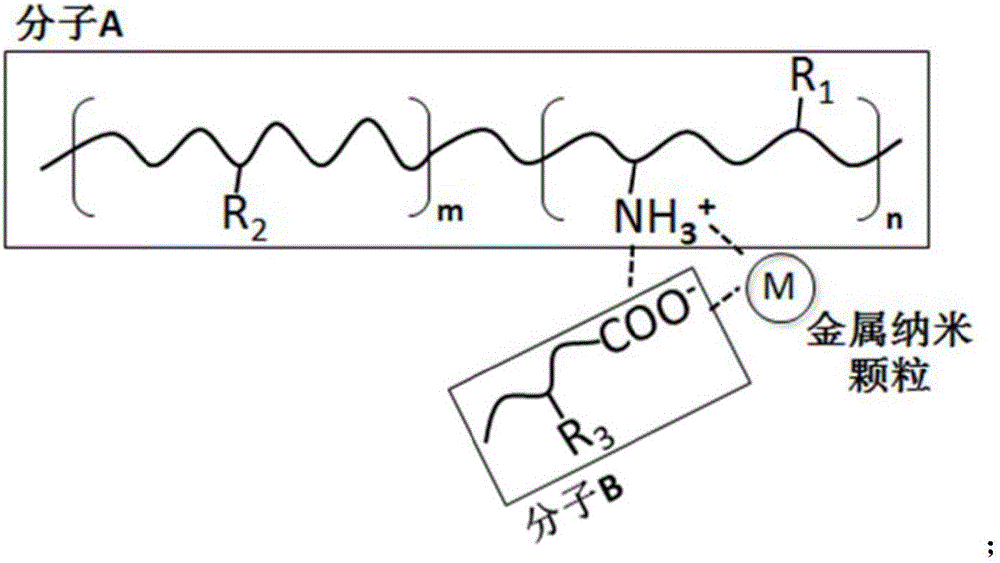

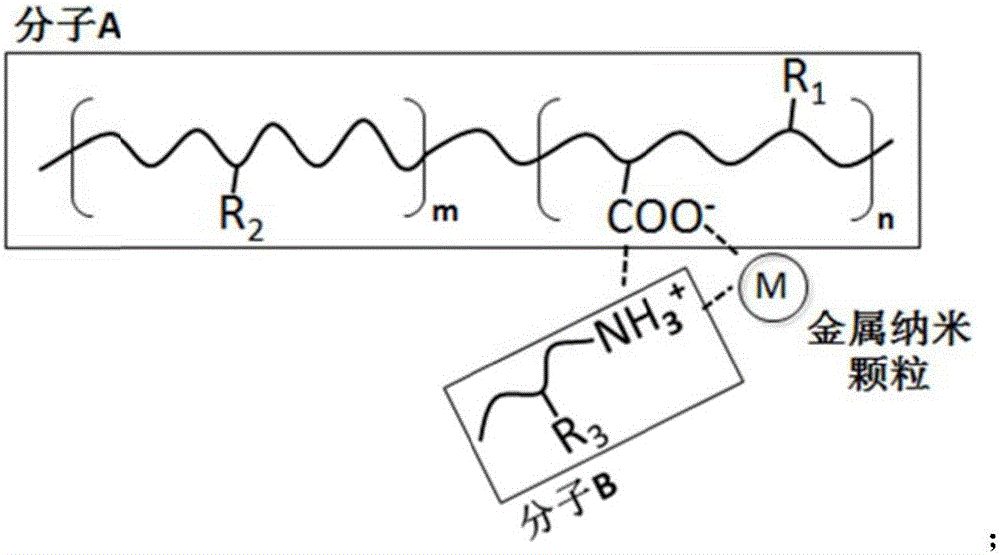

Hybrid material water solution loading metal nanoparticles, and preparation method thereof

A nanoparticle and metal-loaded technology, which is applied in the field of hybrid material aqueous solution loaded with metal nanoparticles and its preparation, can solve the problems of nano-silver product particle size and shape inhomogeneity, unfavorable large-scale industrial production, and no molecular weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A preparation method of an aqueous solution of a hybrid material loaded with Ag nanoparticles. Under the condition of 20° C., the aqueous solution of chitosan containing amino groups with a mass percent concentration of 0.5% and the n-butyric acid containing carboxyl groups with a mass percent concentration of 3 percent are prepared. The aqueous solution is mixed, wherein the relative molecular weight of chitosan is 240000, the molecular weight of n-butyric acid is 88.1, and the molar ratio of chitosan and n-butyric acid is 1:0.3, accompanied by stirring; it is adjusted by 0.1mol / L HCl solution The pH value of the reaction system was brought to 4, and then AgNO with a concentration of 0.005g / mL was added dropwise to the mixture 3 solution, where AgNO 3 The molar ratio to chitosan is 0.1:1, and the stirring is continued for 0.5h after the dropwise addition is completed; the concentration is 0.048g / mL sodium borohydride aqueous solution, wherein AgNO 3 The molar ratio to...

Embodiment 2

[0062] A method for preparing an aqueous solution of a hybrid material loaded with Fe nanoparticles. Under the condition of 60°C, the aqueous solution of carboxymethyl chitosan containing 3% by mass percentage concentration and the carboxyl group-containing chitosan solution of 10% by mass percentage are mixed. N-valeric acid aqueous solution is mixed, and wherein, the relative molecular weight of carboxymethyl chitosan is 10000, and the molecular weight of n-valeric acid is 102.13, and the mol ratio of carboxymethyl chitosan and n-valeric acid is 1:1, with stirring; Using 0.15mol / L of H 2 SO 4 The solution adjusts the pH value of the reaction system to 6, and then drips FeCl with a concentration of 2 g / mL in the mixed solution 2 solution, where FeCl 2 The molar ratio of carboxymethyl chitosan to carboxymethyl chitosan is 10:1, and the stirring is continued for 1 h after the dropwise addition is completed; the concentration is 0.01g / mL potassium borohydride aqueous solution,...

Embodiment 3

[0064] A method for preparing an aqueous solution of a hybrid material loaded with Au nanoparticles. Under the condition of 30° C., an aqueous solution of polyacrylamide containing amino groups with a mass percentage concentration of 1% and a carboxyl-containing n-hexanoic acid aqueous solution with a mass percentage concentration of 4% are prepared. Mix, wherein, the relative molecular weight of polyacrylamide is 1×10 6 , the molecular weight of n-hexanoic acid is 115.15, the molar ratio of polyacrylamide and n-hexanoic acid is 1:0.4, accompanied by stirring; using 0.3mol / L HNO 3 The solution adjusted the pH value of the reaction system to 5, and then added dropwise HAuCl with a concentration of 0.008g / mL in the mixed solution 4 solution, where HAuCl 4 The molar ratio of polyacrylamide to polyacrylamide is 0.5:1, and the stirring is continued for 0.6h after the dropwise addition is completed; a concentration of 0.032g / mL ascorbic acid aqueous solution is added dropwise, in w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com