Ultraviolet-resistant and heat-aging-resistant sheath material for automobile dashboard wire harness and preparation method for ultraviolet-resistant and heat-aging-resistant sheath material

An automotive dashboard, anti-ultraviolet technology, used in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of poor heat aging resistance, poor ultraviolet resistance, etc., and achieve strong heat aging resistance and long aging. , the effect of blocking ultraviolet radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

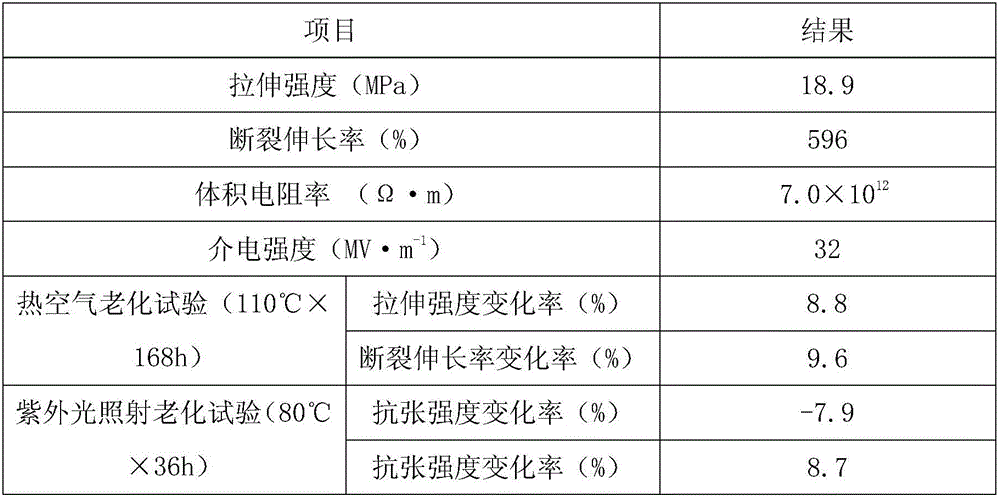

Image

Examples

Embodiment Construction

[0012] An anti-ultraviolet and heat-resistant aging sheath material for automobile instrument panel wiring harness, made of the following raw materials (kg): eva resin 73, trimethylsilyl cage polysilsesquioxane 17, AES resin 23, Petroleum coke residue 17, propylene glycol monosalicylate 16, rare earth tailings 12, erucamide 6, nano-tungsten oxide 8, barium molybdate 7, pyrolysis waste rubber powder 8, isopentyl p-methoxycinnamate Ester 2.5, Cement Slag 12, Diallyl Phthalate 14, Trimethyltin Chloride 4, Pentaerythritol Tetra(2-Ethylhexanoate) 12.

[0013] A preparation method for an anti-ultraviolet and heat-resistant aging sheath material for an automobile instrument panel wiring harness, comprising the following steps:

[0014] (1) Mix petroleum coke slag, rare earth tailings, and cement slag evenly, crush, sieve, then add 20% hydrochloric acid solution equivalent to 5 times the weight of the powder, heat to 56°C in a water bath, ultrasonically oscillate for 35 minutes, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com