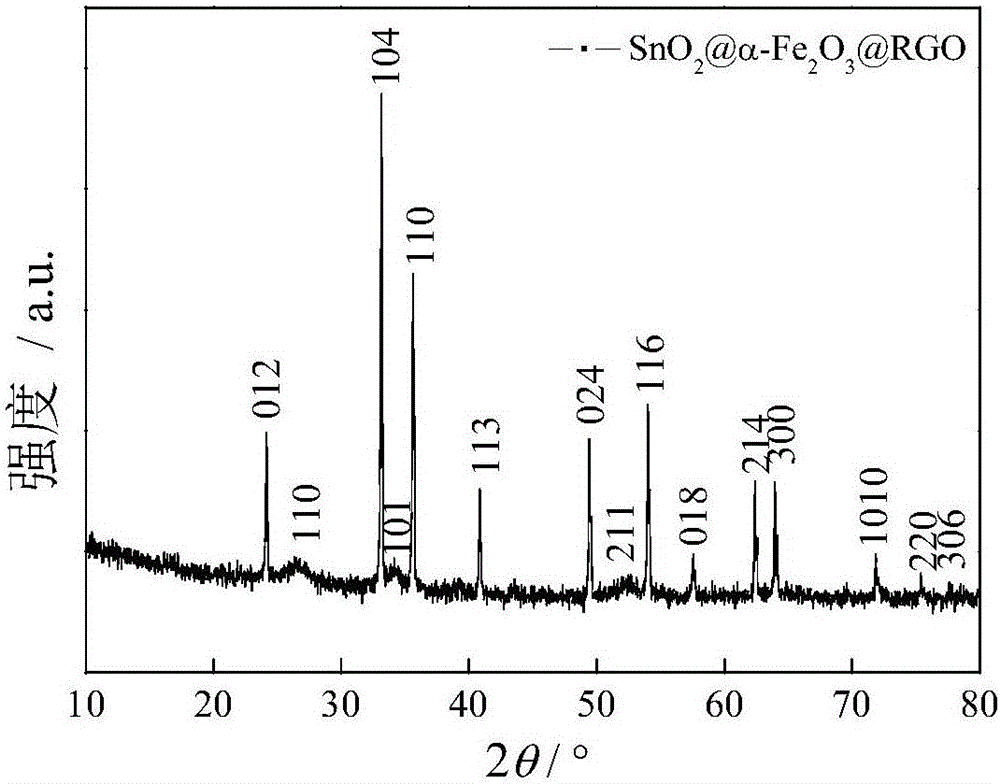

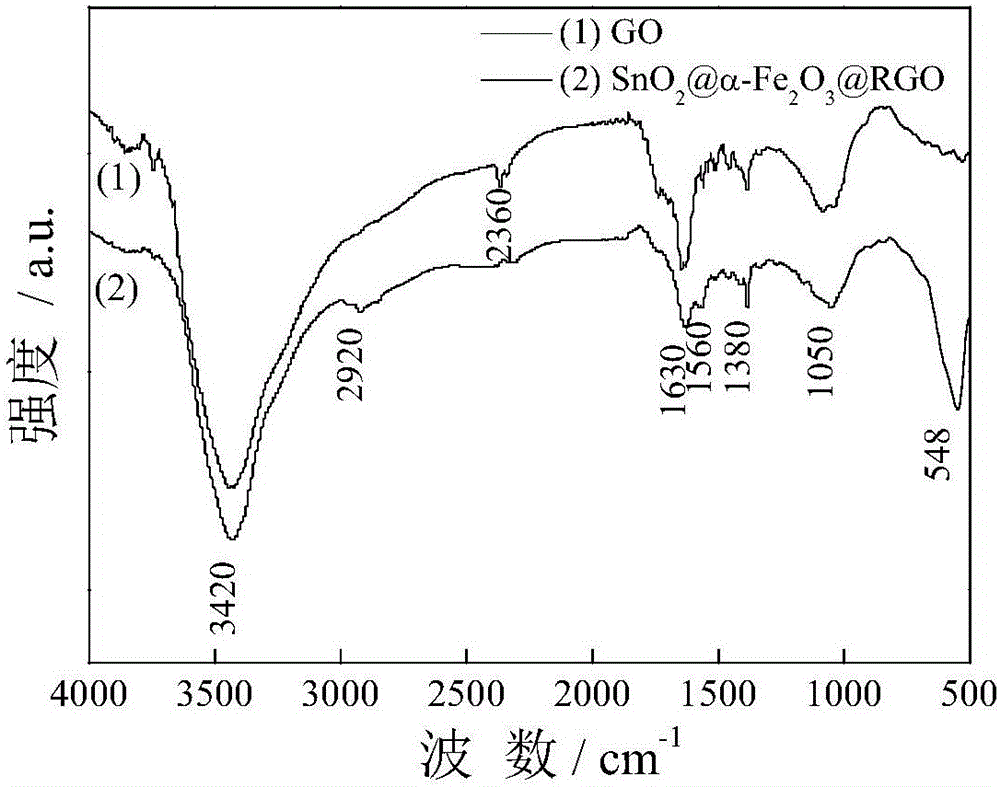

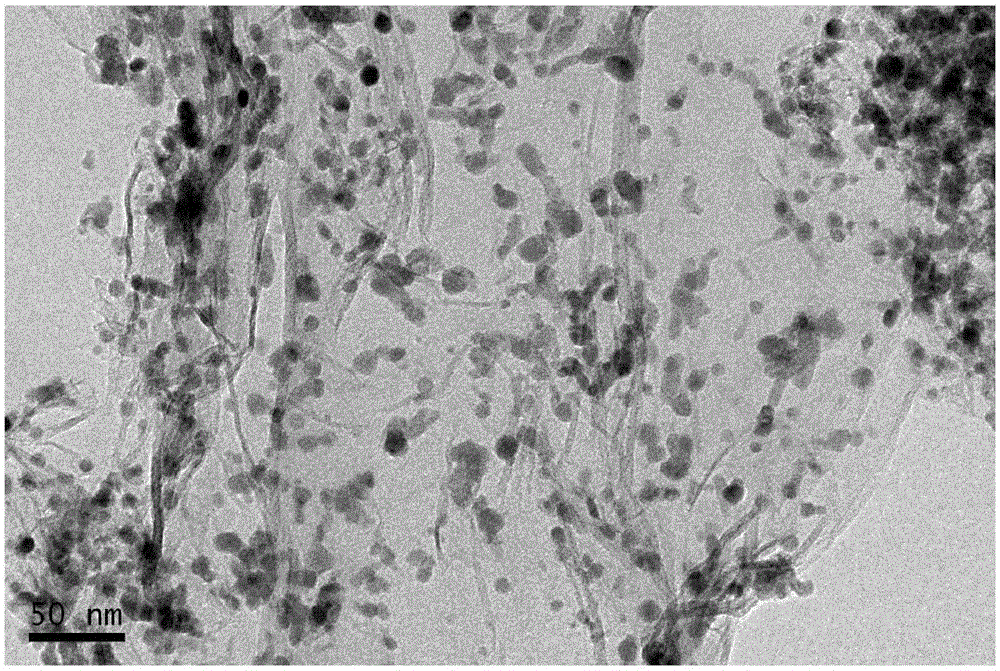

Reduced graphene oxide, tin dioxide and ferric oxide composite material

A technology of ferric oxide and tin dioxide, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve the problems of high density and poor thermal stability, achieve low density, promote peeling, and improve microwave absorption. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The reduced graphene oxide, tin dioxide and ferric oxide composite material of the present invention is prepared according to the following method, comprising steps:

[0033] (1) Preparation of graphene oxide

[0034] Add 3.0g of natural graphite powder and 25g of potassium permanganate into the beaker, mix well, then slowly add 200mL of concentrated sulfuric acid and 20mL of phosphoric acid; stir well, put it into an oil bath, and stir at 70°C for 18 hours; stir After cooling to room temperature, slowly pour the above mixed solution into a plastic beaker filled with 400mL of ice, add 5mL of hydrogen peroxide drop by drop, the solution turns bright yellow to obtain a graphene oxide solution; washing, and then washing with absolute ethanol until nearly neutral, and vacuum drying at 40° C. for 18 hours to obtain graphene oxide powder.

[0035] (2) Preparation of reduced graphene oxide, tin dioxide and ferric oxide microwave absorbing materials

[0036]Add 50 mg of graph...

Embodiment 2

[0038] (1) Preparation of graphene oxide

[0039] Add 3.0g of natural graphite powder and 18g of potassium permanganate into the beaker, mix well, then slowly add 450mL of concentrated sulfuric acid and 30mL of phosphoric acid; stir well, put it in an oil bath, and stir at 50°C for 24 hours; stir After cooling to room temperature, slowly pour the above mixed solution into a plastic beaker filled with 400mL ice, add 10mL hydrogen peroxide drop by drop, the solution turns bright yellow to obtain a graphene oxide solution; washing, and then washing with absolute ethanol until nearly neutral, and vacuum drying at 40° C. for 18 hours to obtain graphene oxide powder.

[0040] (2) Preparation of reduced graphene oxide, tin dioxide and ferric oxide microwave absorbing materials

[0041] Add 80 mg of graphene oxide into a mixed solution of 20 mL of ethanol and 50 mL of deionized water, ultrasonically disperse for 1 hour, then add 0.5406 g of ferric chloride hexahydrate and 5.406 g of ...

Embodiment 3

[0043] (1) Preparation of graphene oxide

[0044] Add 3.0g of natural graphite powder and 18g of potassium permanganate into the beaker, mix well, then slowly add 150mL of concentrated sulfuric acid and 10mL of phosphoric acid; stir well, put it in an oil bath, and stir at 80°C for 12 hours; stir After cooling to room temperature, slowly pour the above mixed solution into a plastic beaker filled with 400mL of ice, add 5mL of hydrogen peroxide drop by drop, the solution turns bright yellow to obtain a graphene oxide solution; washing, and then washing with absolute ethanol until nearly neutral, and vacuum drying at 40° C. for 18 hours to obtain graphene oxide powder.

[0045] (2) Preparation of reduced graphene oxide, tin dioxide and ferric oxide microwave absorbing materials

[0046] Add 20 mg of graphene oxide into a mixed solution of 20 mL of ethanol and 50 mL of deionized water, ultrasonically disperse for 1 hour, then add 0.5406 g of ferric chloride hexahydrate and 0.5406...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com