A kind of L-polylactic acid composite material synergistically reinforced by barium titanate and graphene oxide and its preparation method

A technology of L-polylactic acid and composite material, which is applied in the field of L-polylactic acid composite material and its preparation, can solve the problems of enhancing the piezoelectric performance of the scaffold, insufficient mechanical strength, low cell activity, etc., so as to improve the hydrophilic ability and enhance the mechanical properties. , enhance the effect of interface polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

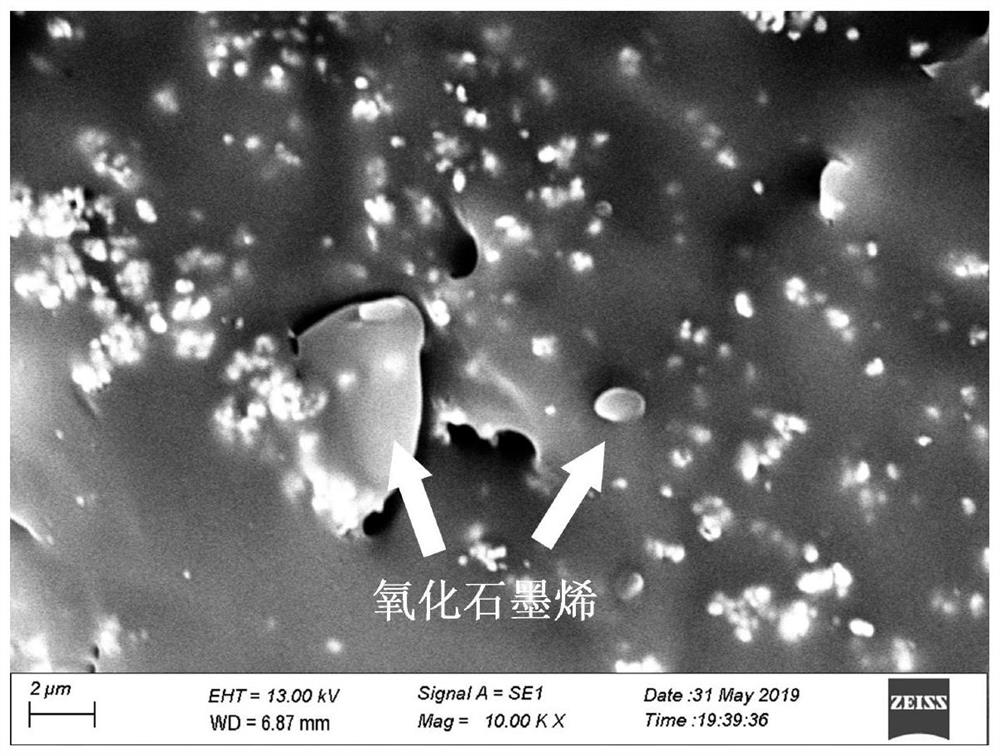

[0034] (1) Use an electronic balance to weigh 0.2g of GO powder with a particle size of 5-15 μm, add it to a beaker containing 30mL of absolute ethanol solution, and obtain a uniform and stable GO suspension under the action of mechanical stirring and ultrasound .

[0035] (2) Use an electronic balance to weigh 10g of BaTiO 3 Powder, the particle size is 0.1 ~ 1μm, added to a beaker filled with 50mL of absolute ethanol solution, under the action of mechanical stirring and ultrasonic, uniform and stable BaTiO 3 suspension.

[0036] (3) Use an electronic balance to weigh 89.8g of PLLA powder with a particle size of 60 μm and a melting point of 180°C, add it to a beaker containing 250mL of absolute ethanol solution, and obtain a uniform and stable powder under the action of mechanical stirring and ultrasound. PLLA suspension; then slowly add PLLA suspension to BaTiO 3and GO in the mixed suspension, and then the mixed solution was uniformly mixed by mechanical stirring and ultr...

Embodiment 2

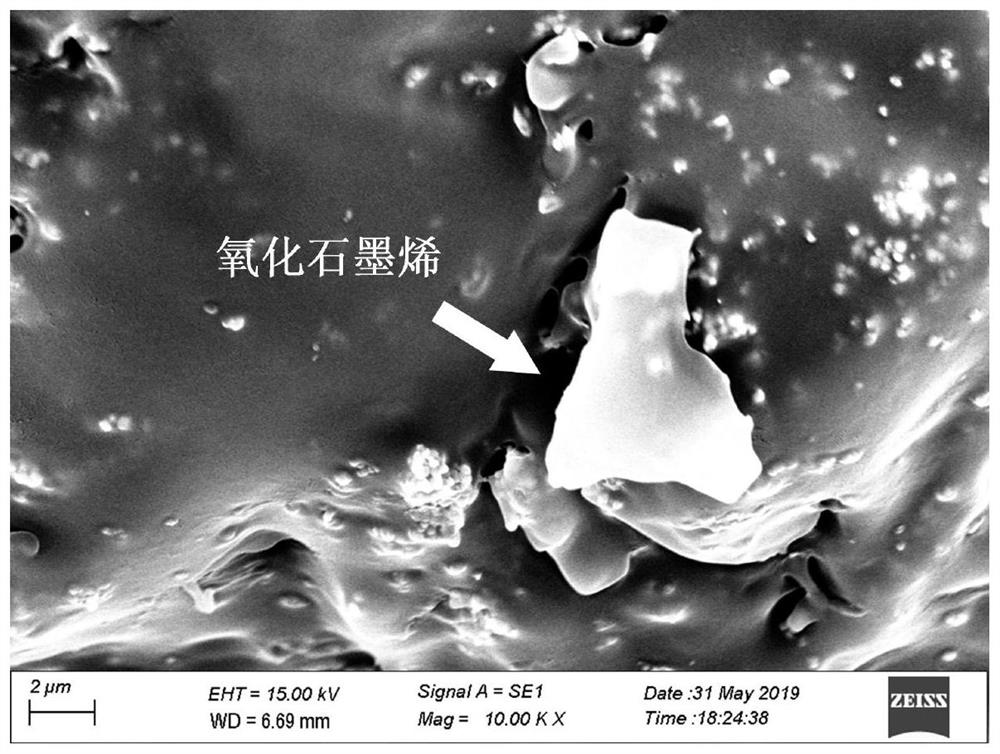

[0042] (1) Use an electronic balance to weigh 0.1g of GO powder with a particle size of 5-15 μm, add it to a beaker containing 30mL of absolute ethanol solution, and obtain a uniform and stable GO suspension under the action of mechanical stirring and ultrasound .

[0043] (2) Use an electronic balance to weigh 10g of BaTiO 3 Powder, the particle size is 0.1 ~ 1μm, added to a beaker filled with 50mL of absolute ethanol solution, under the action of mechanical stirring and ultrasonic, uniform and stable BaTiO 3 suspension.

[0044] (3) Use an electronic balance to weigh 89.9g of PLLA powder with a particle size of 60 μm and a melting point of 180°C, add it to a beaker containing 250mL of absolute ethanol solution, and obtain a uniform and stable powder under the action of mechanical stirring and ultrasound. PLLA suspension; then slowly add PLLA suspension to BaTiO 3 Mix the suspension with GO, and then mix the mixed solution uniformly through magnetic stirring and ultrasonic...

Embodiment 3

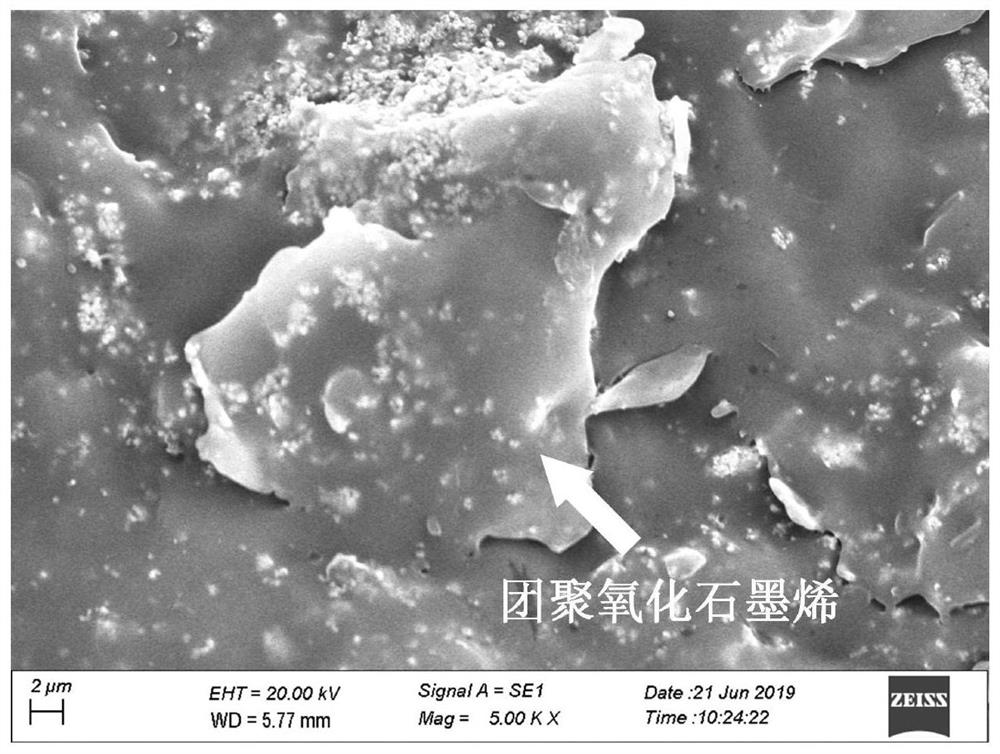

[0050] (1) Use an electronic balance to weigh 0.3g of GO powder with a particle size of 5-15 μm, add it to a beaker containing 30mL of absolute ethanol solution, and obtain a uniform and stable GO suspension under the action of mechanical stirring and ultrasound .

[0051] (2) Use an electronic balance to weigh 10g of BaTiO 3 Powder, the particle size is 0.1 ~ 1μm, added to a beaker filled with 50mL of absolute ethanol solution, under the action of mechanical stirring and ultrasonic, uniform and stable BaTiO 3 suspension.

[0052] (3) Use an electronic balance to weigh 89.7g of PLLA powder with a particle size of 60 μm and a melting point of 180°C, add it to a beaker filled with 250mL of absolute ethanol solution, and obtain a uniform and stable powder under the action of mechanical stirring and ultrasound. PLLA suspension; then slowly add PLLA suspension to BaTiO 3 Mix the suspension with GO, and then mix the mixed solution uniformly through magnetic stirring and ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com