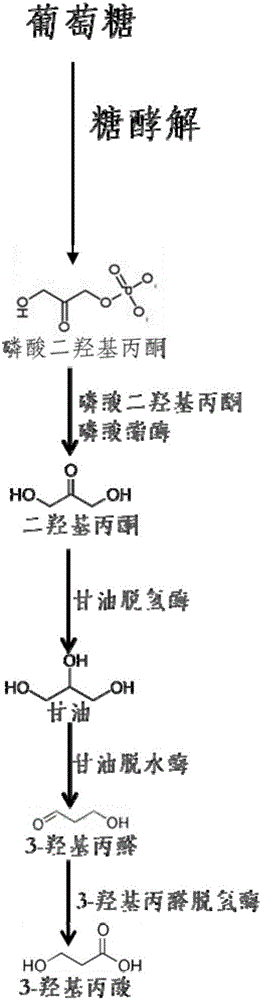

3-hydracrylic-acid-producing recombinant Corynebacterium glutamicum strain, and construction method and application thereof

A technology of Corynebacterium glutamicum and glutamic acid bar, which is applied in the fields of genetic engineering and microbial fermentation, can solve the problems of high price of glycerin, many by-products, and high cost of raw materials, and achieves the solution of biological safety, less by-products, separation of The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

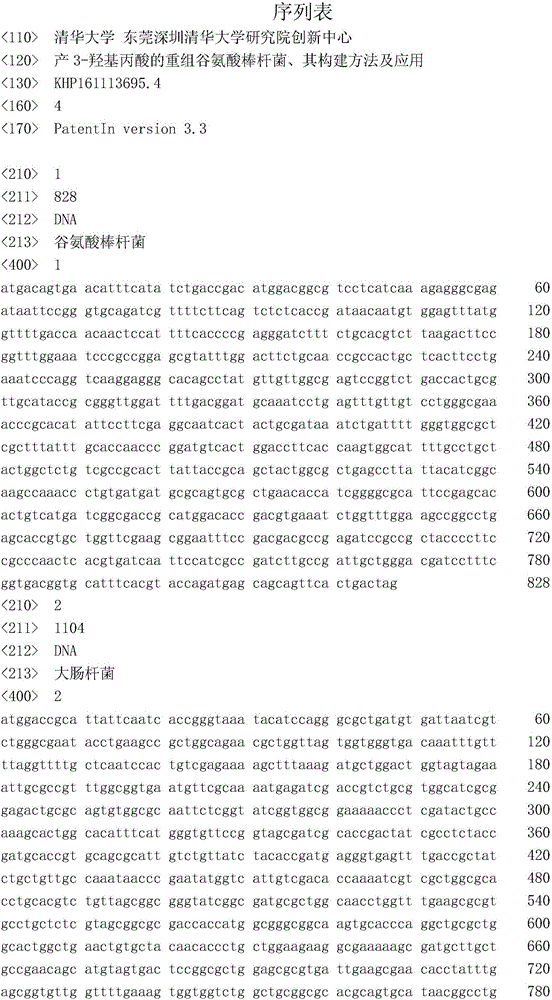

[0036] Example 1 Overexpression of the dihydroxyacetone phosphate phosphatase gene hdpA and the glycerol dehydrogenase gene gldA derived from Escherichia coli in Corynebacterium glutamicum

[0037] Using the genome of Corynebacterium glutamicum ATCC 13032 as a template, PCR was performed with primers hdpA-F (5'-cagctatgaccatgattacgATAAGGCTGATTAGCGGGAAAATTTCG-3') and hdpA-R (5'-CCAGTCGTGTCTAGTCAGTGAACTGCTGCTCATCT-3') to obtain the hdpA gene (hdpA The gene sequence is about 0.9kb (as shown in SEQ ID NO: 1) and the PCR product is purified. Using the genome of Escherichia coli MG1655 as a template, with primers gldA-F (5'-CACTGACTAGACACGACTGGAATGCCGC-3') and gldA-R (5'-atccccgggtaccgagctcgttaTTCCCACTCTTGCAGGAAACGC-3') as primers, PCR was carried out to obtain the gldA gene (gldA gene sequence as SEQ ID NO: 2) about 1.2kb and PCR product purification. The Escherichia coli-Corynebacterium glutamicum shuttle plasmid pEC-K18mob2 (Journal of Biotechnology 104 (2003) 287-299) was diges...

Embodiment 2

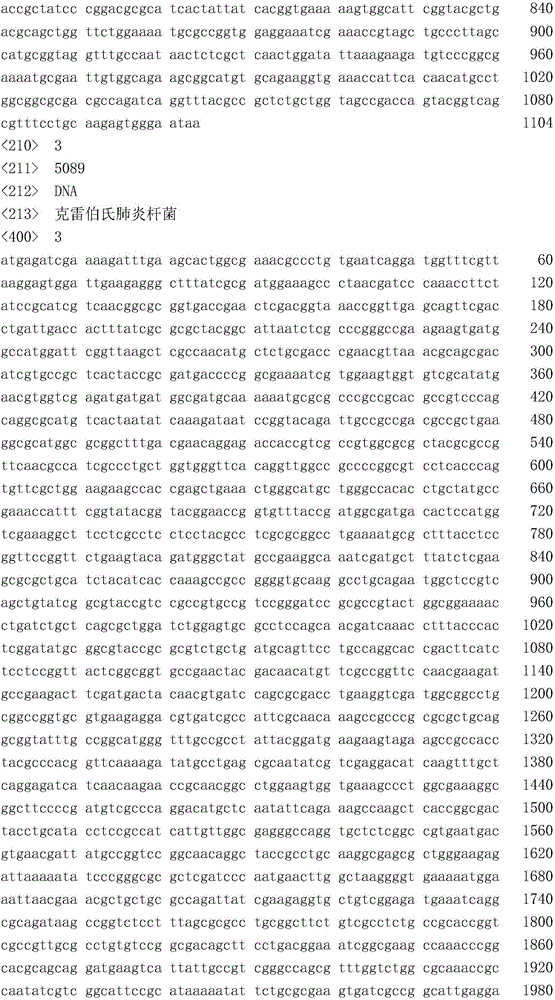

[0038] Example 2 Overexpression of glycerol dehydratase and its activator gene pduCDEGH from Klebsiella pneumoniae and 3-hydroxypropionaldehyde dehydrogenase gene aldH from Escherichia coli

[0039] Using the genome of Klebsiella pneumoniae HR526 as a template, PCR was performed with primers pdu-F (5'-GGAGGCCtgaAAGGAGATATACCATGAGATCGAAAAGATTTG-3') and pdu-R (5'-gctcggtacccggggatcctTTAAGCATGGCGATCCCGAAAT-3') to obtain glycerol dehydratase The pduCDEGH operator fragment (sequence shown in SEQ ID NO: 3) and its activator were purified by PCR. Using the genome of Escherichia coli HR526 as a template, PCR was performed with primers aldH-F (5′-tgcatgcctgcaggtcgactCTGACGTTCACAAACTGCATATATCTGATAGAC-3′) and aldH-R (5′-TATATCTCCTTtcaGGCCTCCAGGCTTATCCA-3′) to obtain 3-hydroxypropionate dehydrogenase Gene aldH fragment (sequence shown in SEQ ID NO: 4) and purified. The Escherichia coli-Corynebacterium glutamicum shuttle plasmid pXMJ19 was digested with XbaI, and the pduCDEGH operon fragm...

Embodiment 3

[0040] Example 3 Fermentative production of 3-hydroxypropionic acid by recombinant Corynebacterium glutamicum

[0041] Corynebacterium glutamicum wild strain ATCC 13032 and recombinant bacteria C. glutamicum / pEC-hdpA-gldA, C. glutamicum / pEC-hdpA-gldA / pXMJ-aldH-pdu were cultured on LB plates overnight. Single bacterium colony was inoculated from this fresh flat board to the 250ml belt baffle shake flask that contains 30ml seed culture medium, 32 ℃ 200rpm cultivated 12 hours, the OD of gained seed solution 600 The value is 10.

[0042] The formulation of the seed medium includes (g / L): Glucose 25, (NH 4 ) 2 SO 4 5.0,K 2 HPO 4 1.5, MgSO 4 1.0, MnSO 4 0.005, FeSO 4 0.005, corn steep liquor 30, kanamycin 0.025.

[0043] Inoculate the seed liquid into 2L fermentation medium with an inoculation amount of 10% (v / v), use a 5L fermenter for fermentation, control the temperature at 32°C, and the ventilation rate at 1vvm, adjust the speed to keep the dissolved oxygen level at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com