Fe@C@g-C3N4 nanometer composite and preparation method and application thereof

A nanocomposite, g-c3n4 technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that nanocomposite microwave absorbing materials have not been reported, and achieve excellent microwave absorption Ability, preparation process conditions are simple, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

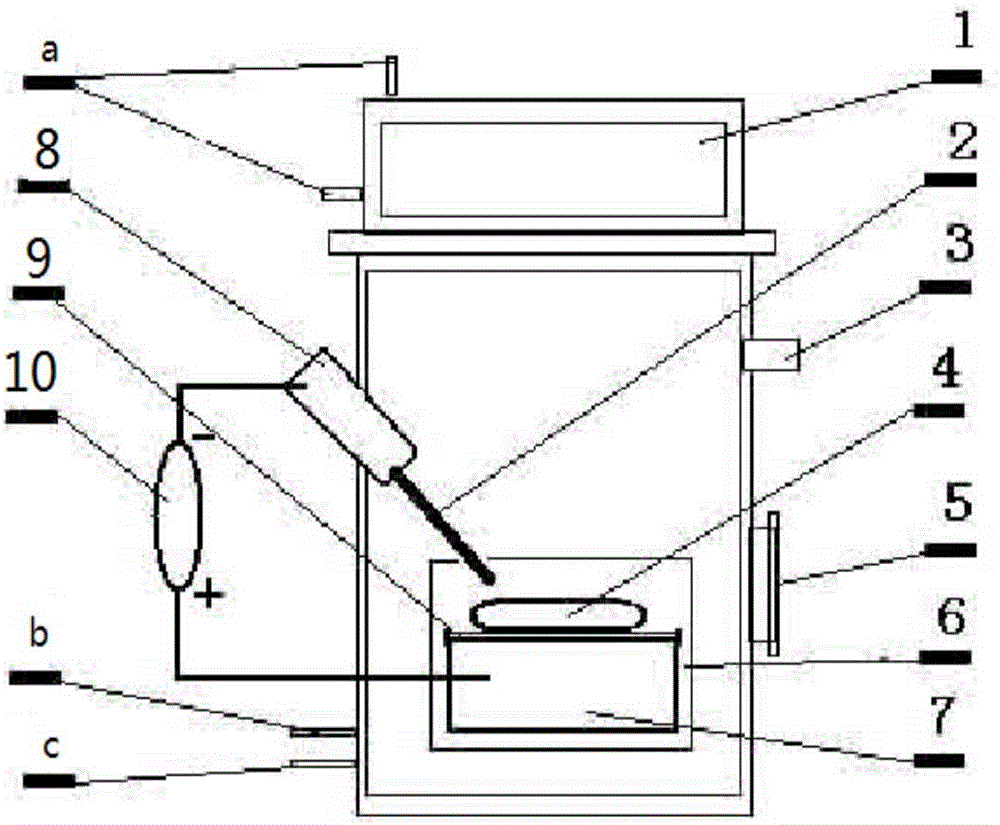

Embodiment 1

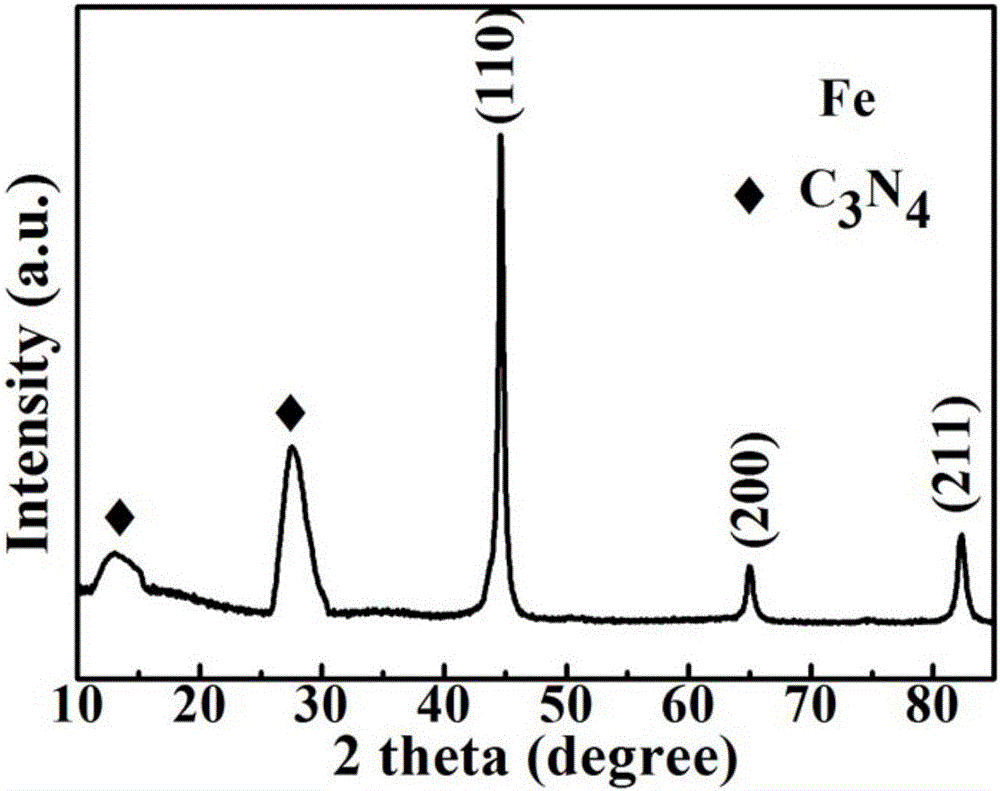

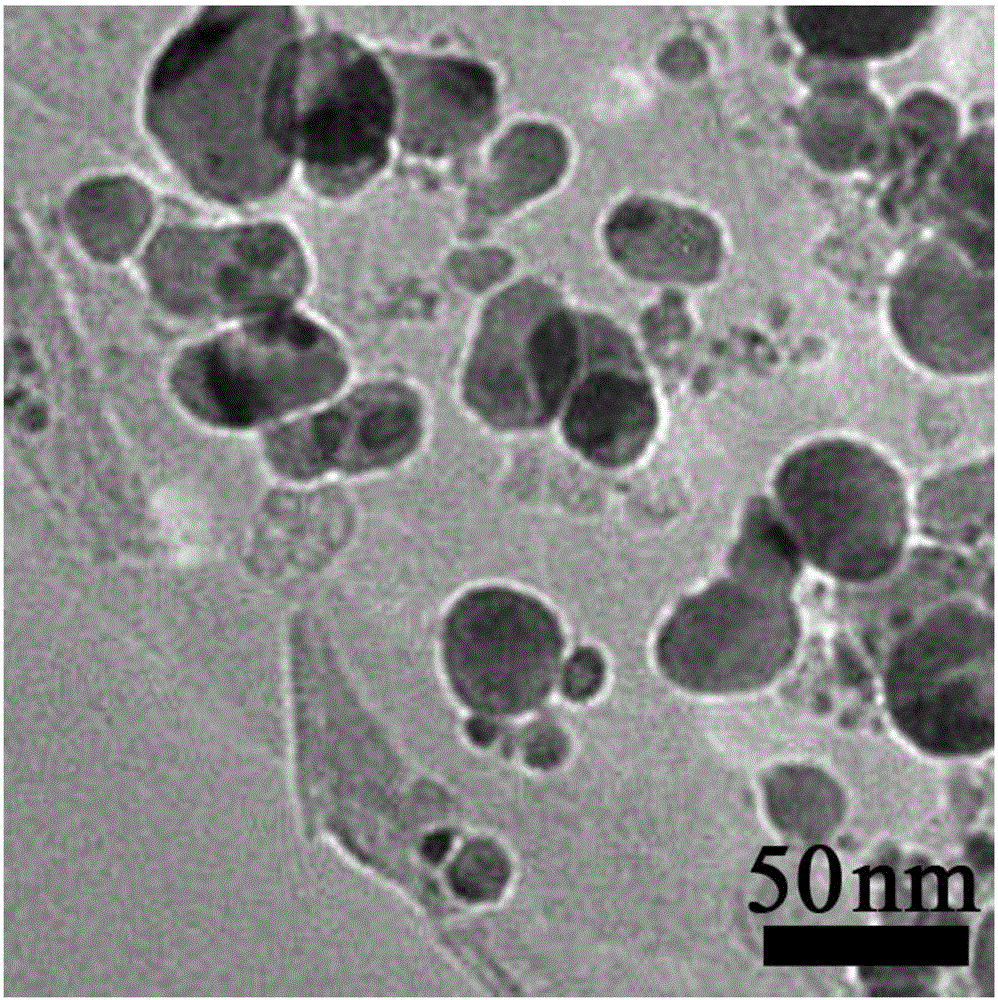

[0032] Will figure 1 The upper cover 1 of the shown device is opened, and graphite is used as the cathode 2 to fix it on the chuck 8. The anode target 4 consumed is a block pressed from pure iron powder and melamine powder (mass ratio 90:10). On the copper anode 7 passing through the cooling water, between the copper anode 7 and the anode target 4 is a graphite crucible 9 . A distance of 30 mm is maintained between the cathode 2 and the anode target 4 . Cover the upper cover 1 of the device, pass cooling water a, and after the whole working chamber is evacuated through the valve 3, argon gas b and methane gas c are introduced, the partial pressure of argon gas is 0.5MPa, and the partial pressure of methane gas is 0.3MPa , connect the DC pulsating power supply 10, the voltage is 40V, adjust the working current and voltage to keep relatively stable during the arc discharge process, and Fe@C@g-C 3 N 4 nanocomposites. The microstructure of the nanocomposite is Fe@C core-shell ...

Embodiment 2

[0034] Will figure 1The upper cover 1 of the device shown is opened, and graphite is used as the cathode 2 to fix it on the chuck 8. The anode target 4 consumed is a block pressed from pure iron powder and melamine powder (mass ratio 70:30). On the copper anode 7 passing through the cooling water, between the copper anode 7 and the anode target 4 is a graphite crucible 9 . A distance of 30 mm is maintained between the cathode 2 and the anode target 4 . Cover the upper cover 1 of the device, pass cooling water a, and after the whole working chamber is evacuated through the valve 3, argon gas b and methane gas c are introduced, the partial pressure of argon gas is 0.5MPa, and the partial pressure of methane gas is 0.3MPa , connect the DC pulsating power supply 10, the voltage is 10V, adjust the working current and voltage to keep relatively stable during the arc discharge process, and obtain Fe@C@g-C 3 N 4 nanocomposites. The microstructure of the nanocomposite is Fe@C core-...

Embodiment 3

[0036] Will figure 1 The upper cover 1 of the shown device is opened, and graphite is used as the cathode 2 to fix it on the chuck 8. The anode target 4 consumed is a block pressed from pure iron powder and melamine powder (mass ratio 90:10). On the copper anode 7 passing through the cooling water, between the copper anode 7 and the anode target 4 is a graphite crucible 9 . A distance of 2 mm is maintained between the cathode 2 and the anode target 4 . Cover the upper cover 1 of the device, pass cooling water a, and after the whole working chamber is evacuated through the valve 3, argon gas b and methane gas c are introduced, the partial pressure of argon gas is 0.5MPa, and the partial pressure of methane gas is 0.3MPa , connect the DC pulsating power supply 10, the voltage is 20V, adjust the working current and voltage to keep relatively stable during the arc discharge process, and obtain Fe@C@g-C 3 N 4 nanocomposites. The microstructure of the nanocomposite is Fe@C core-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com